A mobile feeding tool for long seam welding

A long weld seam and tooling technology, which is applied in the field of mobile feeding tooling for long weld seam welding, can solve the problems of long weld seam welding limitations, etc., and achieve the effects of reducing equipment scale, simple structure, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

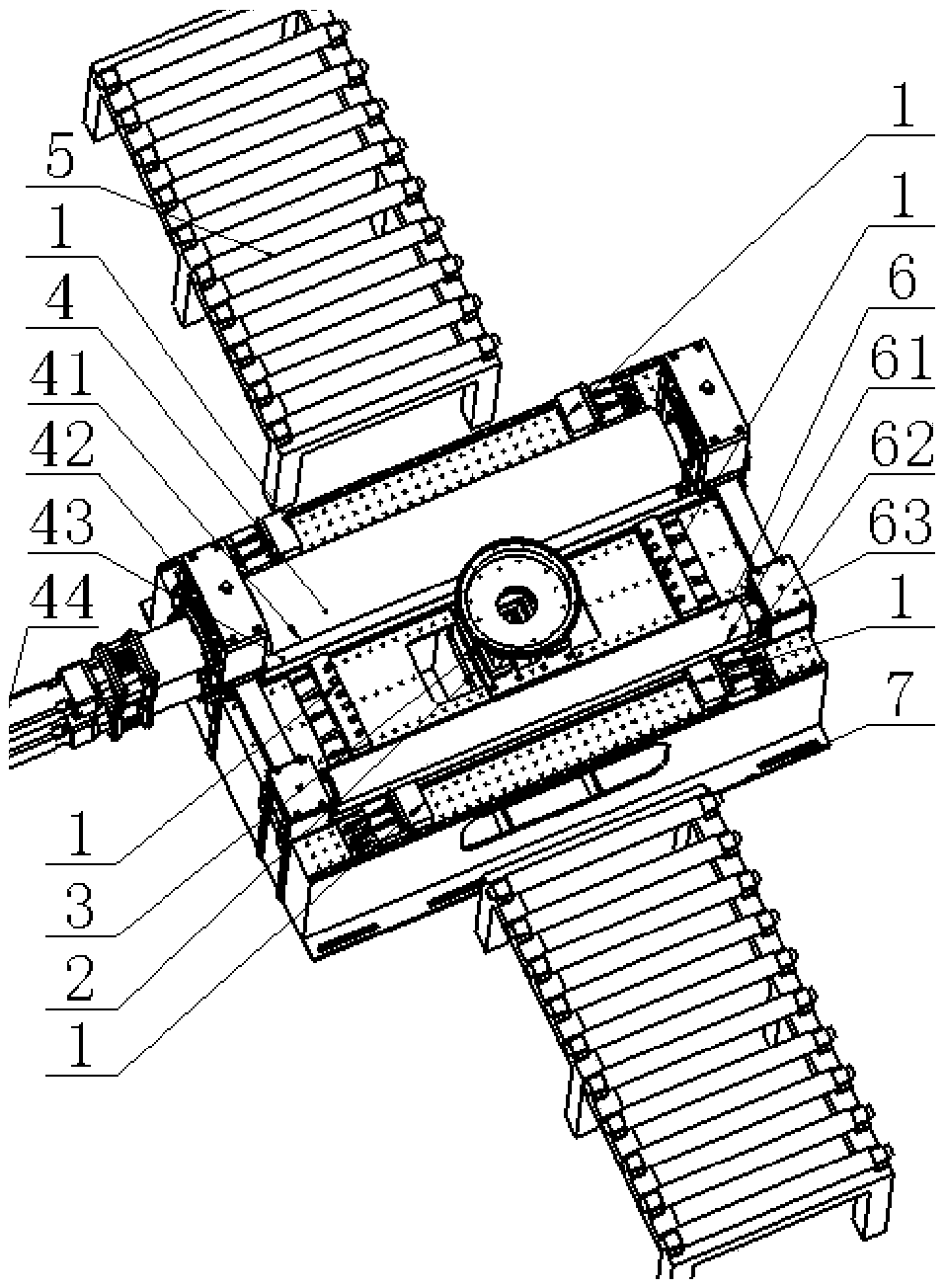

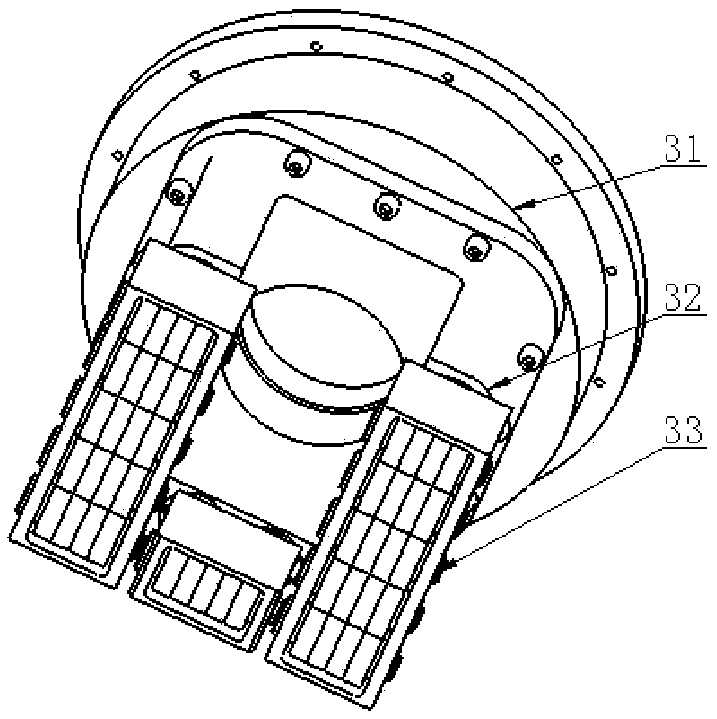

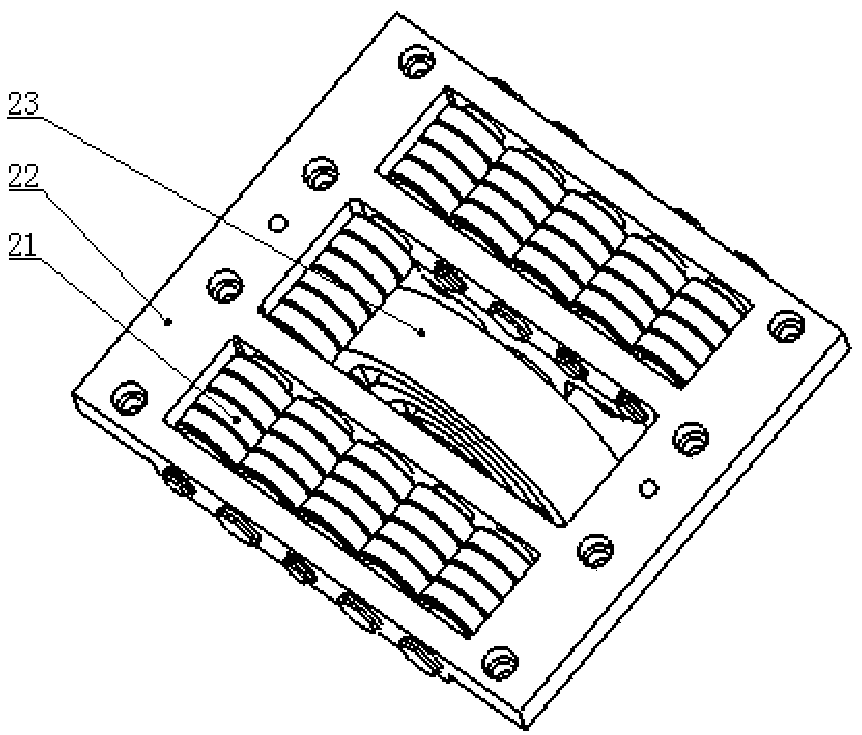

[0032] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0033] Such as Figure 1-6 As shown, the mobile feeding tool for long weld seam welding of the present invention includes a lateral limit mechanism 1, a back support mechanism 2, an upper side pressing mechanism 3, a driving roller mechanism 4, a supporting plate mechanism 5, a driven roller mechanism 6 and Substrate7. Wherein the lateral limit mechanism 1 and the back support mechanism 2 are all connected with the base body 7 by bolts, and the mutual positional relationship between the side limit mechanism 1 and the back support mechanism 2 and the base body 7 is changed by changing the connecting threaded holes respectively; The tightening mechanism 3 is connected with the headstock of the welding equipment by bolts to provide the pressing force during the friction stir welding process of the aluminum plate. Through the move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com