Temperature-control automatic on-off type water fire extinguishing control valve

A valve control, opening and closing technology, applied in valve details, valve device, fire rescue and other directions, can solve the problems of water cut off, secondary combustion of combustibles, short spray water time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

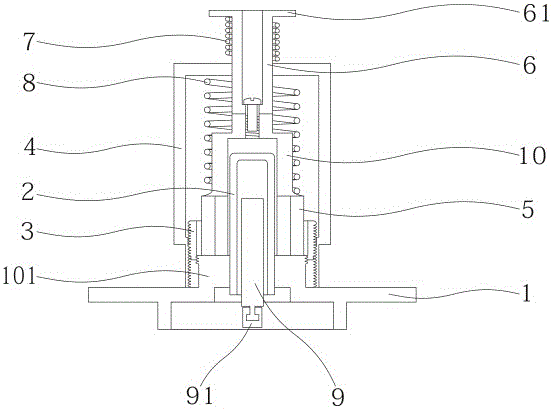

[0017] like figure 1 The structure of the temperature-controlled automatic opening and closing water fire extinguishing control valve shown includes a connecting end cover 1, a sleeve 2, an intermediate connecting section 3, a fixed cap 4, a magnetic ring sleeve 5, a telescopic rod 6, and a one-way memory alloy telescopic spring. 7, compression spring 8, movable column 9.

[0018] The center of the connecting end cover 1 is provided with an upwardly protruding connecting block 101, and a stepped hole is provided on the connecting end cover 1 corresponding to the connecting block 101; the rear part of the connecting block 101 is connected with a cylinder shaped sleeve 2; the outside of the connecting block 101 is provided with external threads, the fixed cap 4 is connected to the connecting block 101 through the intermediate connecting section 3, and the inner edge of the bottom of the fixed cap 4 is threaded, so Said middle connecting section 3 is threaded inside and outside,...

Embodiment 2

[0020] Embodiment 2 Improvement of the one-way memory alloy telescopic spring:

[0021] CuZnAl memory alloy spring

[0022] The spring is made of CuZnAl memory alloy wire and utilizes the two-way memory effect of shape memory alloy. This kind of spring fully demonstrates the typical structural form of industrial shape memory alloy elements.

[0023] With hot water or hot air as the heat source, the stretching temperature is 80°C-95°C, the free state is 45mm at low temperature (room temperature), and the stretched state is 200mm at high temperature (80°C-95°C).

[0024] The present invention has also carried out further improvement to CuZnAl memory alloy spring, and its preparation method is as follows:

[0025] (1) Determine memory alloy becomes, according to mass percentage:

[0026] Zn18%, Al4.5%, Ni1.1%, Ti0.2%, Fe0.05%, the rest is Cu;

[0027] (2) Preprocessing:

[0028] Put the memory alloy into the pretreatment solution and keep it at 30°C for 15-20 minutes. The fo...

Embodiment 3

[0033] Embodiment 3 Improvement of the one-way memory alloy telescopic spring:

[0034] CuZnAl memory alloy spring

[0035] The spring is made of CuZnAl memory alloy wire and utilizes the two-way memory effect of shape memory alloy. This kind of spring fully demonstrates the typical structural form of industrial shape memory alloy elements.

[0036] With hot water or hot air as the heat source, the stretching temperature is 80°C-95°C, the free state is 45mm at low temperature (room temperature), and the stretched state is 200mm at high temperature (80°C-95°C).

[0037] The present invention has also carried out further improvement to CuZnAl memory alloy spring, and its preparation method is as follows:

[0038] (1) Determine memory alloy becomes, according to mass percentage:

[0039] Zn21%, Al4.3%, Ni1.1%, Ti0.2%, Fe0.05%, the rest is Cu;

[0040] (2) Preprocessing:

[0041] Put the memory alloy into the pretreatment solution and keep it at 30°C for 15-20 minutes. The fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com