Full-range image detecting system and method thereof

An image detection and image technology, which is applied in the field of detection system, can solve the problems of affecting the process, the speed of focusing is not fast enough, prolonging the detection time, etc., and achieves the effect of low cost, fast focusing speed and breaking through the bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

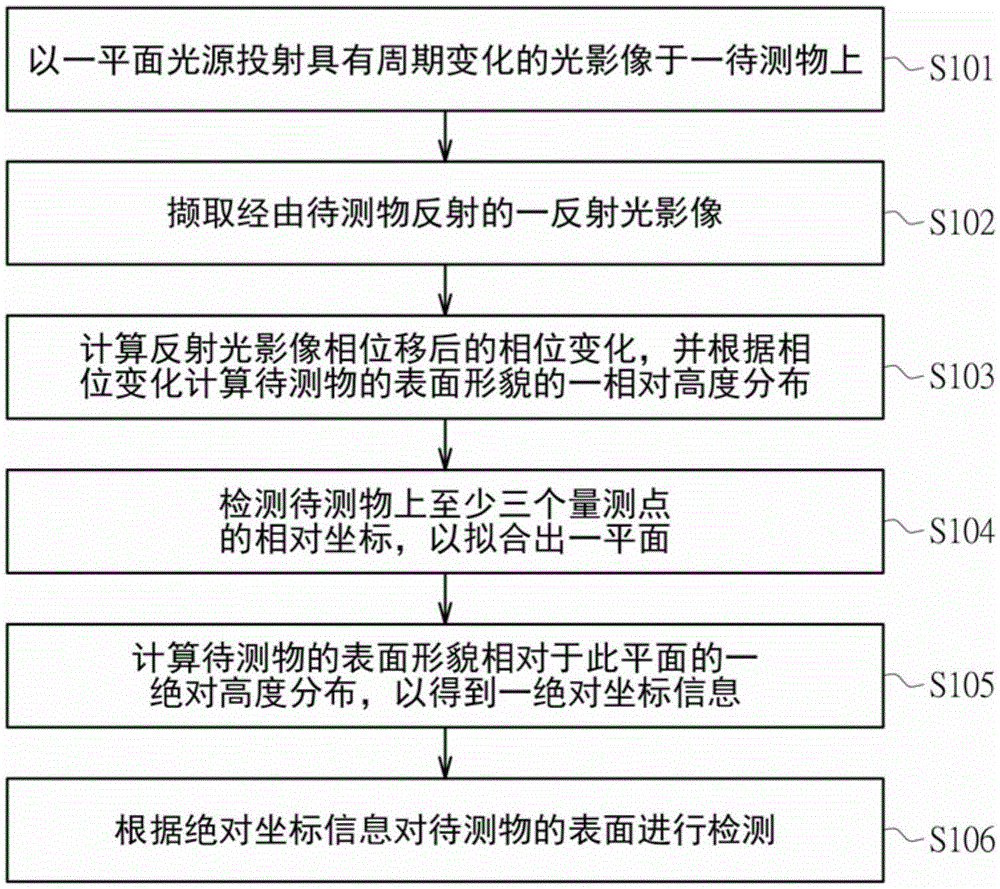

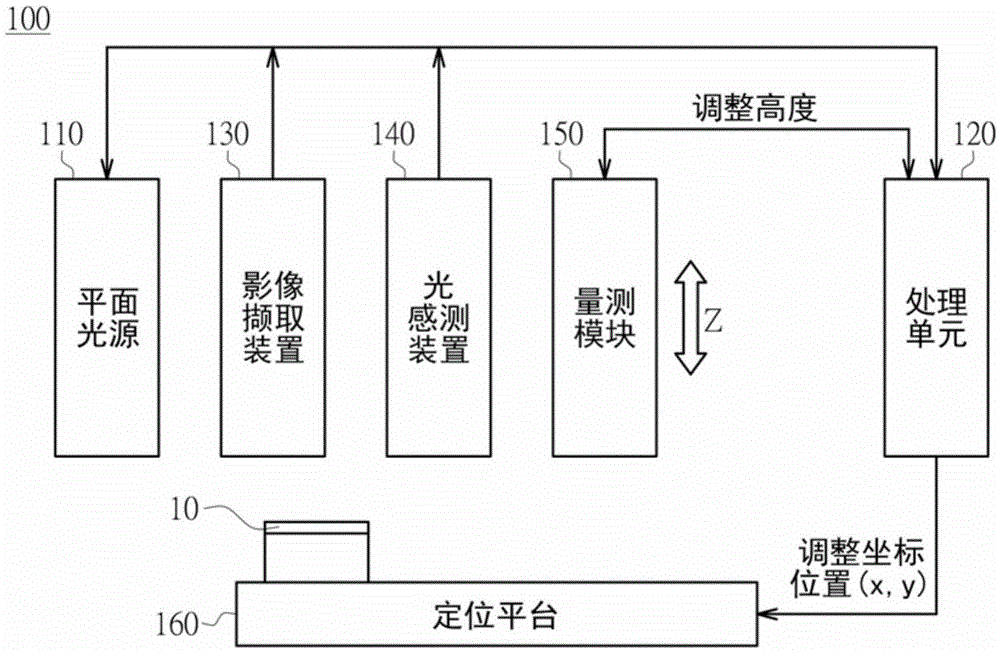

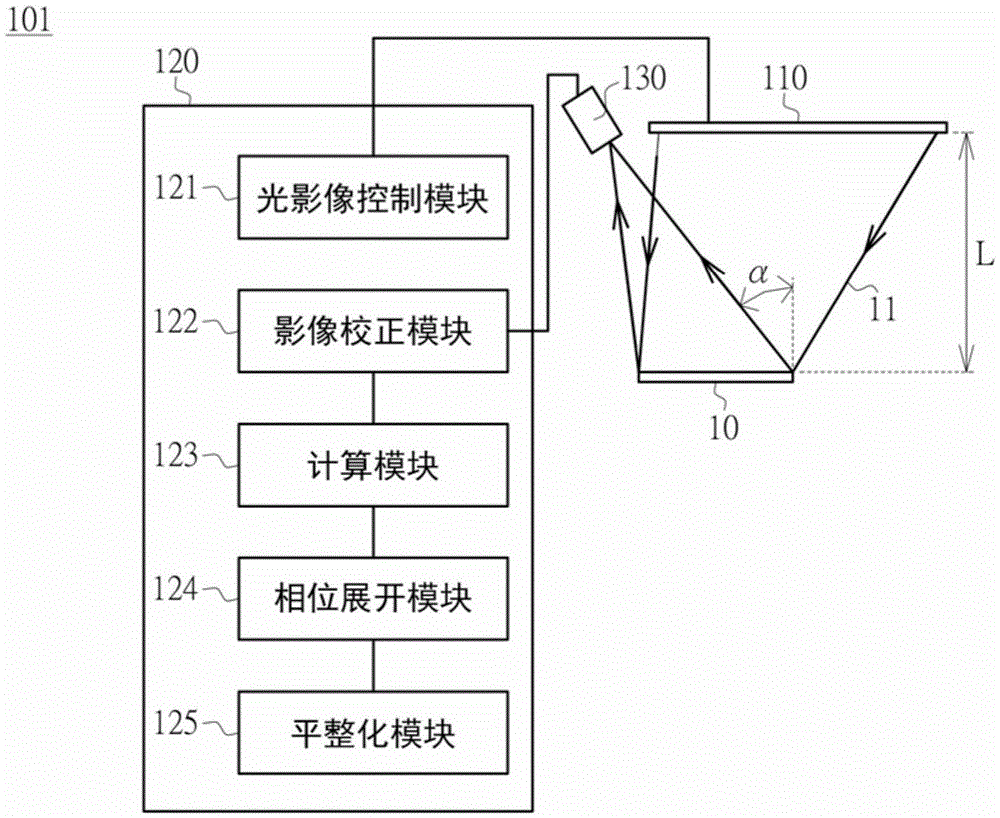

[0040] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0041] The global image inspection system and its inspection method of this embodiment measure the surface topography and relative height distribution of the object to be inspected (such as a wafer), and output reference coordinate information (such as the center position of the wafer, alignment Groove position, rotation angle, and image resolution, etc.), as the movement information of the measurement module (such as an optical microscope or optical interferometer) and the positioning platform, shortens the focusing time, and enables the measurement module to perform point-by-point rapid measurement.

[0042] Taking wafer surface detection as an example, the relative height distribution of the surface topography of the wafer is measured first, and the relative height and reference coordinate information of the surface topograp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com