Multilayer film neutral gray scale density filter and manufacturing method thereof

一种中性灰度、多层膜的技术,应用在光学、滤光片、光学元件等方向,能够解决易产生鬼影等问题,达到效果好、反射率低、光线平衡衰减好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

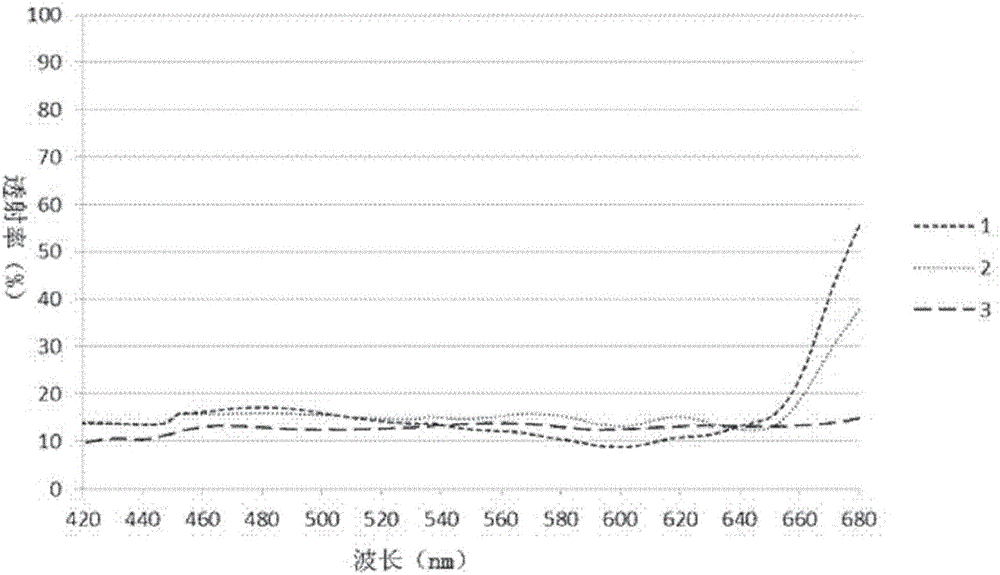

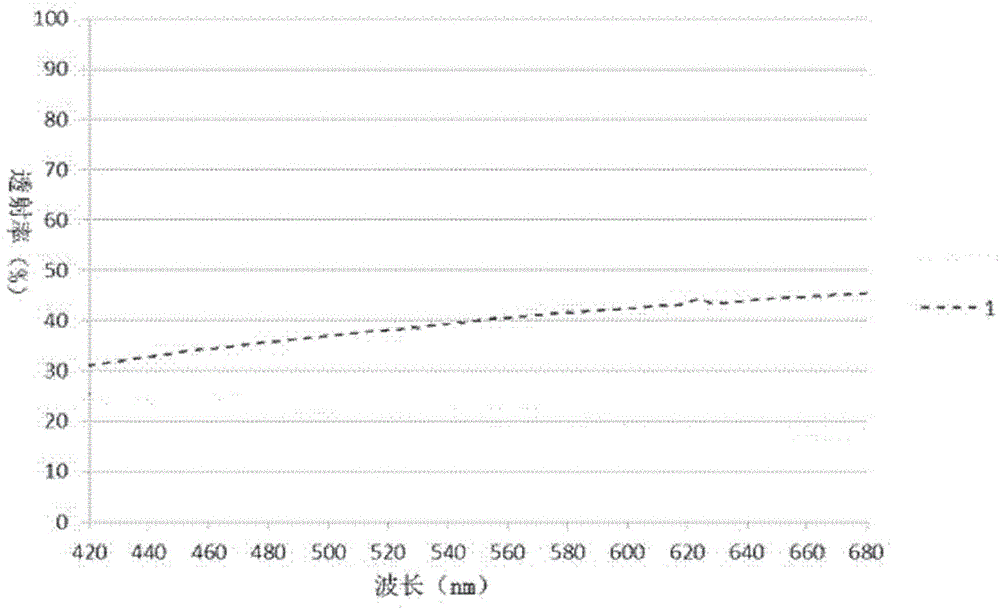

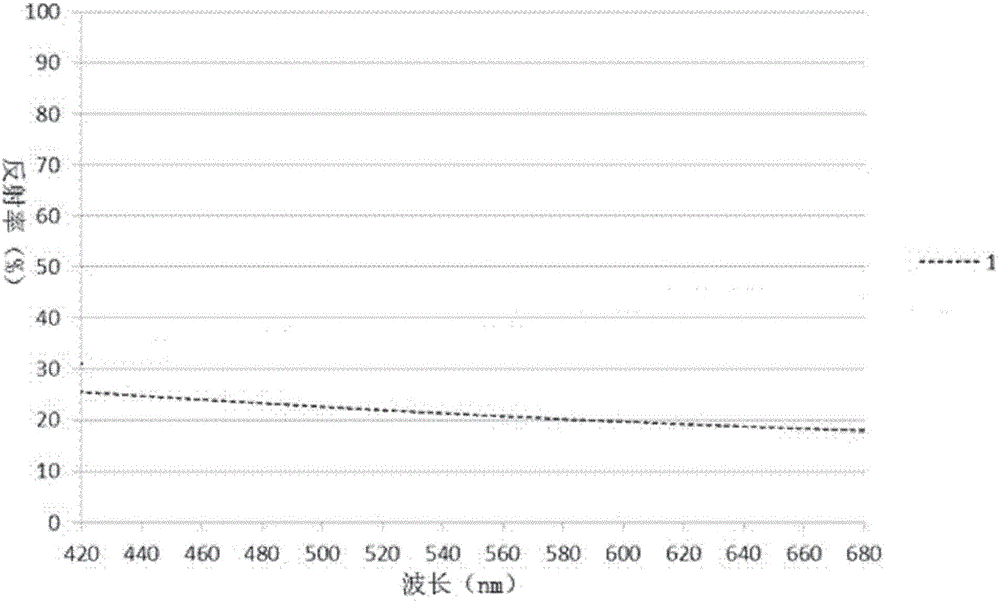

[0031] The neutral gray-scale light reduction filter of multi-layer film layer comprises a substrate, and several layers of film layers are coated on the substrate, and the film layer includes laminated anti-reflection films and metal films, and at least A layer of anti-reflection film, and a multi-layer anti-reflection film may also be provided between two adjacent metal films, and the refractive index of the constituent material of the anti-reflection film is greater than 1.30.

[0032] Preferably, the constituent material of the anti-reflection film includes at least one selected from Al 2 o 3 , AlF 3 , BeO, CaF 2 , CeF 3 , CeO 3 、Cr 2 o 3 、Dy 2 o 3 、Gd 2 o 3 , HfO 2 、Ho 2 o 3 、In 2 o 3 、LaF 3 , MgF 2 , MgO, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| reflectivity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com