Method for masking bitterness of collagen peptide composition

一种胶原蛋白肽、组合物的技术,应用在苦味掩盖领域,能够解决不愉快臭味等问题,达到效果有效、降低苦味的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

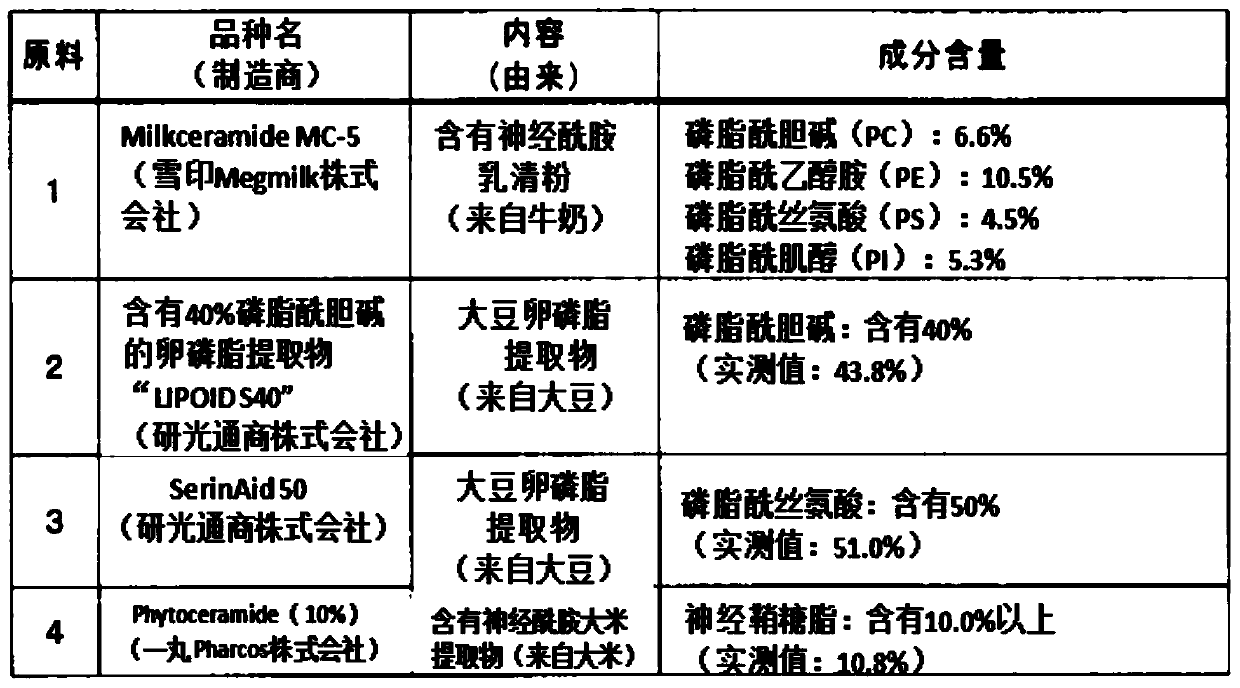

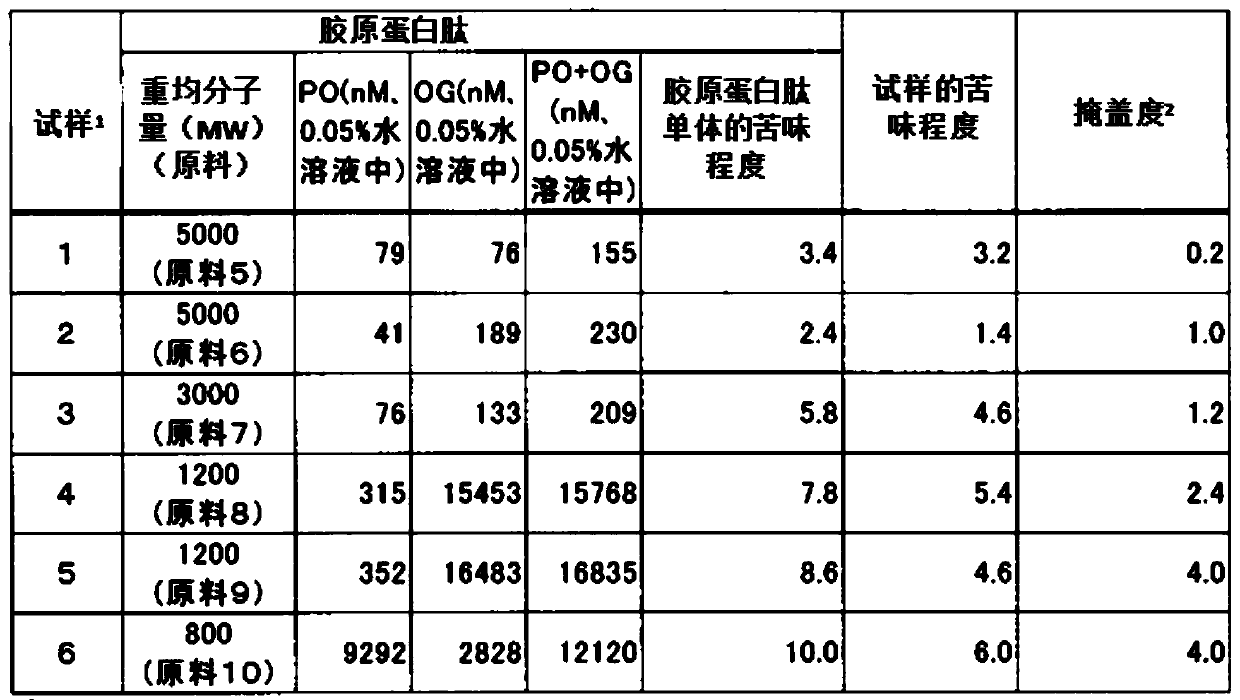

[0097] Example 1: Masking Effect of Bitter Ceramide Raw Materials on Collagen Peptides

[0098]

[0099] In order to confirm the bitterness-masking effect of the ceramide raw material, first, the degree of bitterness of the collagen peptide was evaluated.

[0100] (Evaluation method)

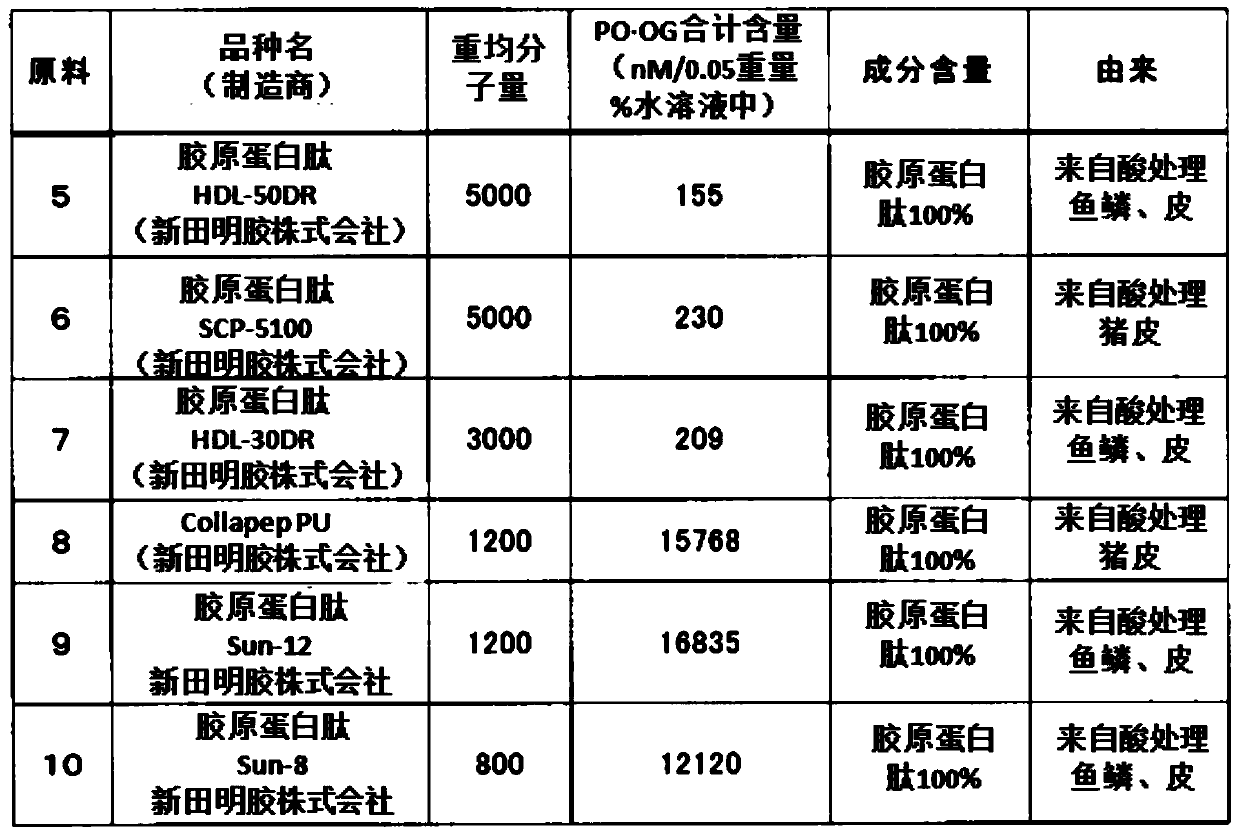

[0101] Collagen peptides (raw materials 5 to 10 in Table 2) with different weight average molecular weights or origins were used for sensory evaluation. Specifically, the powder (0.5 g) of each collagen peptide was ingested, and the bitterness of the collagen peptide monomer was evaluated. degree. In addition, the PO (Pro-Hyp) content and the OG (Hyp-Gly) content of each collagen peptide were measured, and the correlation between these contents and bitterness was evaluated together. Here, the sensory evaluation was carried out by five trained panelists. The sensory evaluation was performed on a scale of 10 from 0 (no bitterness felt at all) to 10 (most bitterness felt). The degree of bitte...

Embodiment 2

[0122] Example 2: Evaluation of the Mixing Ratio of Collagen Peptides and Various Glycerophospholipids

[0123] Using high concentrations of neutral and acidic glycerophospholipids, the compounding ratio of collagen peptides and various glycerophospholipids effective in masking the bitter taste of collagen peptides was studied.

[0124]

[0125]According to the method of Example 1, the collagen peptide (raw material 9 in Table 2) and the neutral glycerophospholipid raw material (raw material 2 in Table 1) or the acidic glycerophospholipid raw material (raw material 3 in Table 1) were mixed in the ratio shown in Table 4 , Samples 7-13 were prepared, and sensory evaluation was performed. The results are shown in Table 4.

[0126]

[0127] First, as shown in Table 4, it was found that the higher the ratio of the glycerophospholipid to the collagen peptide, the higher the masking effect, and the effect was significant when the neutral glycerophospholipid was used. In additio...

Embodiment 3

[0133] Example 3: Research on the Optimum Ratio of Neutral Glycerophospholipids and Acidic Glycerophospholipids

[0134] The optimum ratio of neutral glycerophospholipids and acid glycerophospholipids, which show the bitter taste masking effect of collagen peptides, was studied by changing the compounding ratio of glycerophospholipids contained in raw materials.

[0135]

[0136] Raw materials having a high glycerophospholipid content (raw materials 2 and 3 in Table 1) were blended at the ratios shown in Table 5 to prepare ceramide raw materials. The obtained ceramide raw material was mixed with collagen peptide (raw material 9 in Table 2) to prepare samples 19 to 23, and the masking effect of each sample was evaluated. Table 5 shows the results. It should be noted that the preparation and sensory evaluation of samples were carried out according to the method in Example 1.

[0137]

[0138] As shown in Table 5, it was found that when the ratio of neutral glycerophospholip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com