Preparation method of Chinese prickly ash sauce

A production method and technology of Sichuan pepper sauce, which are applied in the direction of fat oil/fat refining, fat production, fat oil/fat production, etc., can solve the problems of low utilization rate of pepper particles, and achieve the effect of high utilization rate and simple and intelligent operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of pepper sauce preparation method, comprises the following steps:

[0026] A. Raw material preparation: choose dried peppercorns with uniform size and no impurities as raw materials for standby;

[0027] B. Pulverization: Put the prepared pepper raw materials into a pulverizer for crushing, and then sieve through a sieving machine after crushing, and select pepper powder with a particle size of 20 mesh to 60 mesh;

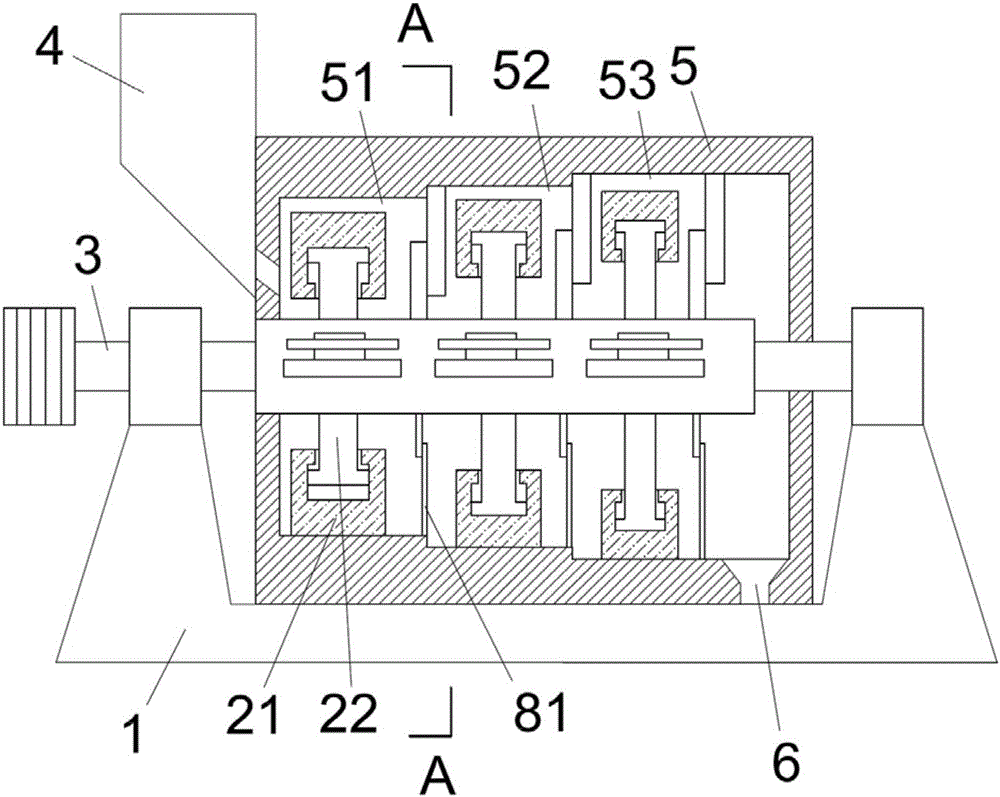

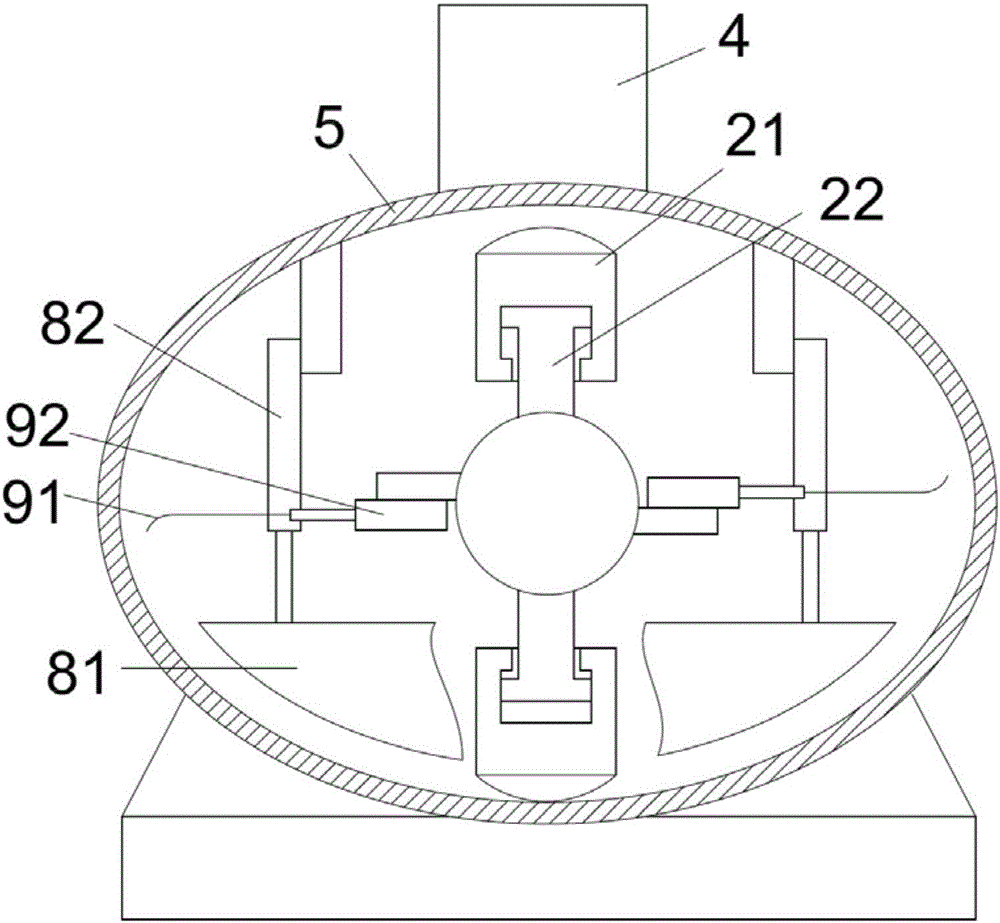

[0028] refer to figure 1 , figure 2 , the pulverizer includes a cylinder 5, the cylinder 5 adopts an elliptical structure in cross section, one end of the cylinder 5 is provided with a material inlet 4 for putting in the prickly ash principle, and the other end of the cylinder 5 is provided with a device for collecting prickly ash powder. Outlet 6, a support frame 1 is provided at the bottom of the cylinder body 5, a power spindle 3 passes through the middle of the cylinder body 5, both ends of the power spindle 3 are supported by the support fram...

Embodiment 2

[0038] A kind of pepper sauce preparation method, comprises the following steps:

[0039] A. Raw material preparation: choose dried peppercorns with uniform size and no impurities as raw materials for standby;

[0040] B. Pulverization: Put the prepared pepper raw materials into a pulverizer for crushing, and then sieve through a sieving machine after crushing, and select pepper powder with a particle size of 40 mesh to 50 mesh;

[0041] refer to figure 1 , figure 2 , the pulverizer includes a cylinder 5, the cylinder 5 adopts an elliptical structure in cross section, one end of the cylinder 5 is provided with a material inlet 4 for putting in the prickly ash principle, and the other end of the cylinder 5 is provided with a device for collecting prickly ash powder. Outlet 6, a support frame 1 is provided at the bottom of the cylinder body 5, a power spindle 3 passes through the middle of the cylinder body 5, both ends of the power spindle 3 are supported by the support fram...

Embodiment 3

[0051] A kind of pepper sauce preparation method, comprises the following steps:

[0052] A. Raw material preparation: choose dried peppercorns with uniform size and no impurities as raw materials for standby;

[0053] B. Pulverization: Put the prepared pepper raw materials into a pulverizer for crushing, and then sieve through a sieving machine after crushing, and select pepper powder with a particle size of 50 mesh to 80 mesh;

[0054] refer to figure 1 , figure 2 , the pulverizer includes a cylinder 5, the cylinder 5 adopts an elliptical structure in cross section, one end of the cylinder 5 is provided with a material inlet 4 for putting in the prickly ash principle, and the other end of the cylinder 5 is provided with a device for collecting prickly ash powder. Outlet 6, a support frame 1 is provided at the bottom of the cylinder body 5, a power spindle 3 passes through the middle of the cylinder body 5, both ends of the power spindle 3 are supported by the support fram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com