Closed loop airflow pulverizing system

A technology of airflow crushing and closed-circuit circulation, which is applied in grain processing and other fields, and can solve the problems of quality and waste of raw materials that are difficult to produce by crushing equipment, and achieve the effect of intelligent operation, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

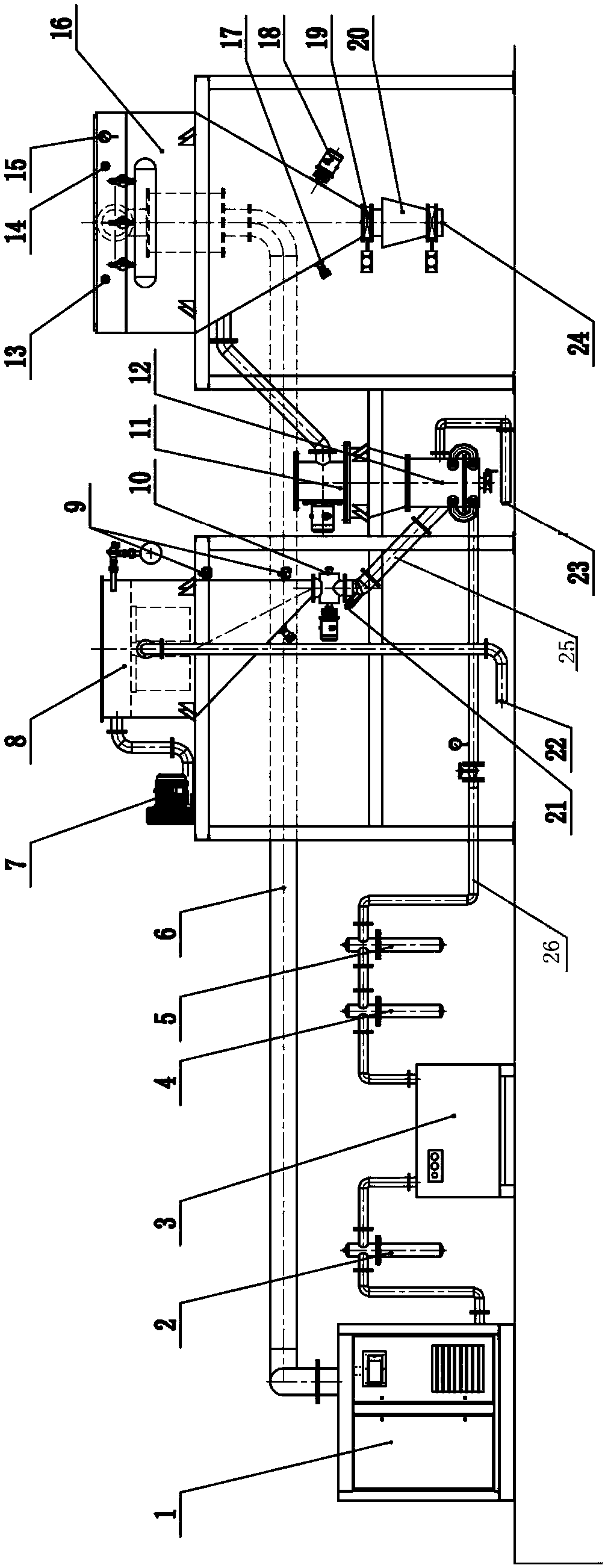

[0024] like figure 1 , figure 2 As shown, the present invention includes a crushing and grading device for crushing materials, a feeding device for feeding, and a powder collecting device for collecting finished powder; it also includes a gas compressor for gas medium circulation, The outlet pipe 26 of the gas compressor is connected to the crushing and grading device, and the inlet pipe 6 of the gas compressor is connected to the exhaust port of the powder collection device; the gas compressor supplies compressed inert gas or pure air. The gas compressor supplies compressed inert gas or pure air. Inert gas sources include nitrogen, argon, and the like.

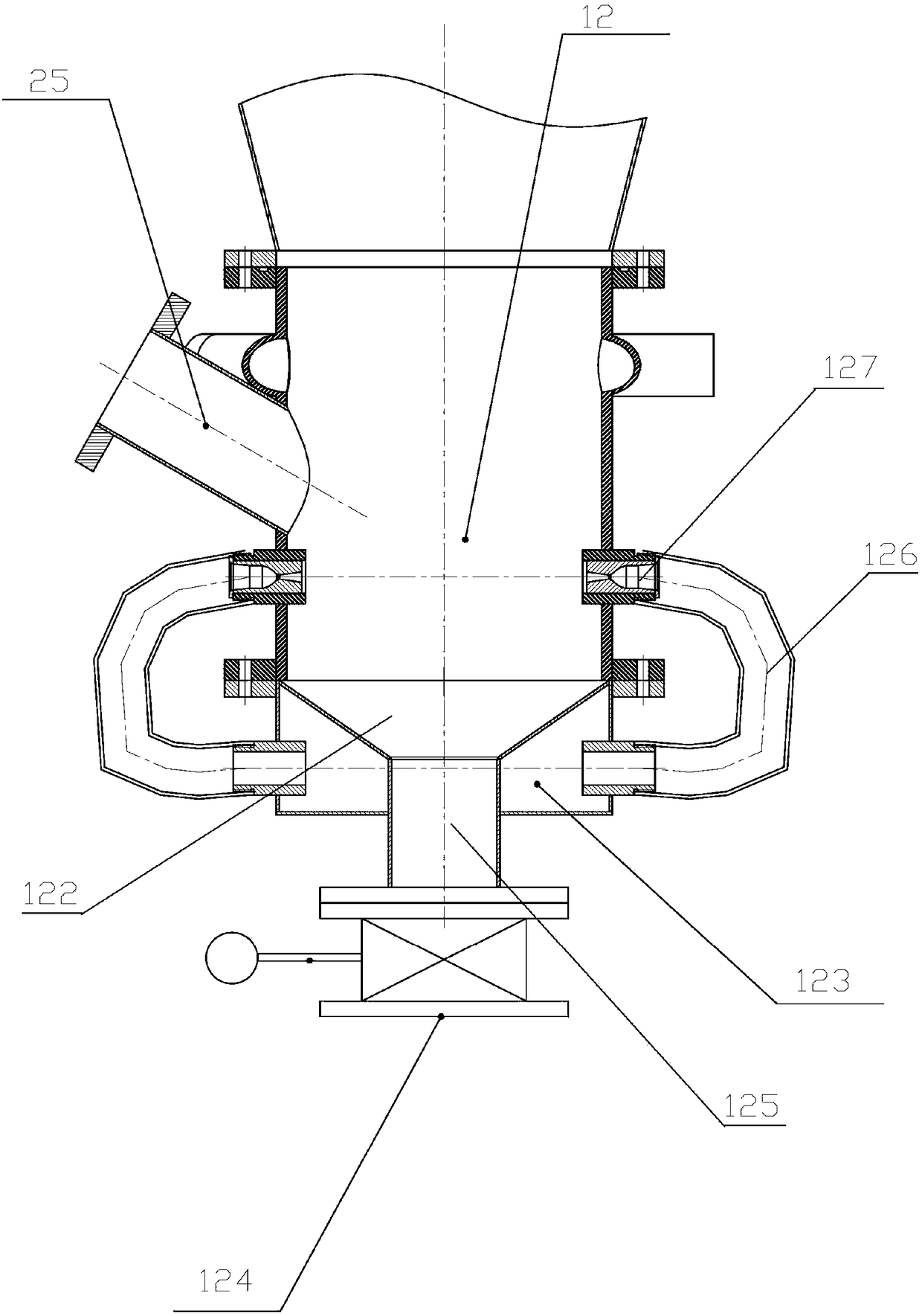

[0025] The crushing and grading device includes a crushing chamber 12 and a classification ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com