Cast tube crusher

A crusher and cast pipe technology, applied in grain processing and other directions, can solve the problems of cast iron scraps and cement blocks splashing, labor costs, personal injury to workers, etc., achieving remarkable crushing effect, high work efficiency, and controllable crushing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is described in further detail:

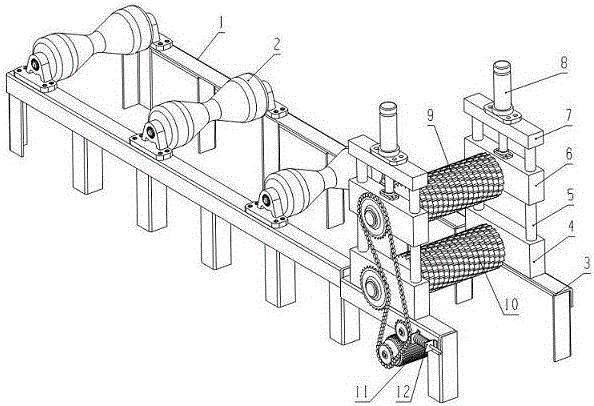

[0022] Such as figure 1 Shown is a structural diagram of the present invention. The invention is a machine for crushing defective cast pipes, and simultaneously separates the cement lining on the inner wall of the cast pipe from the cast pipe body during the crushing process. The present invention mainly includes a first support 1 placed horizontally on the ground and a second support 3 installed on one side of the first support 1 . The first support 1 has a rectangular structure and includes two beams arranged parallel to each other and several mutually symmetrical vertical feet arranged under the two beams. Three bearing frames are evenly installed on the two beams of the first support 1, the positions of the bearing frames on the two beams are corresponding, and bearings are installed on the bearing frames. Three conveying rollers 2 are installed on the two beams of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com