An electric combined vibration type grain grading device

A grading device and vibrating technology, which is applied in the field of separation devices for removing impurities in grains, to achieve stable operation, high stratification efficiency, and avoid linear vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

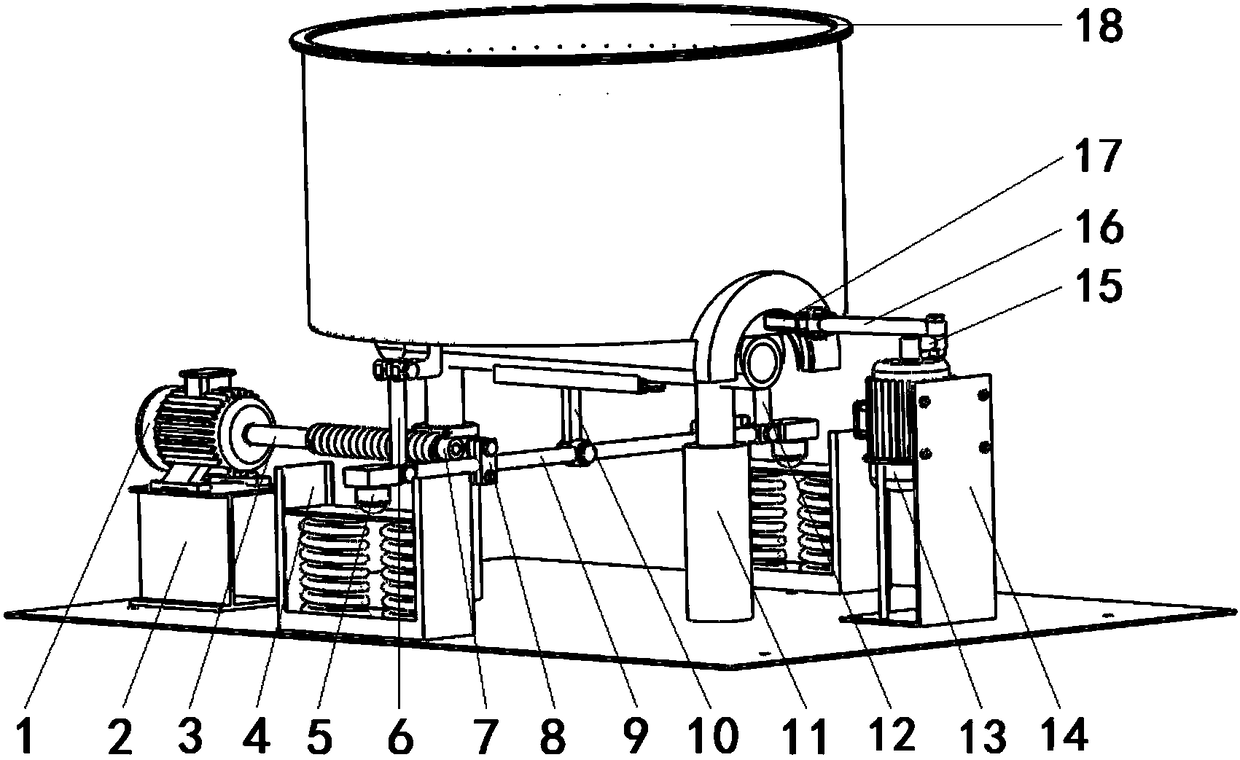

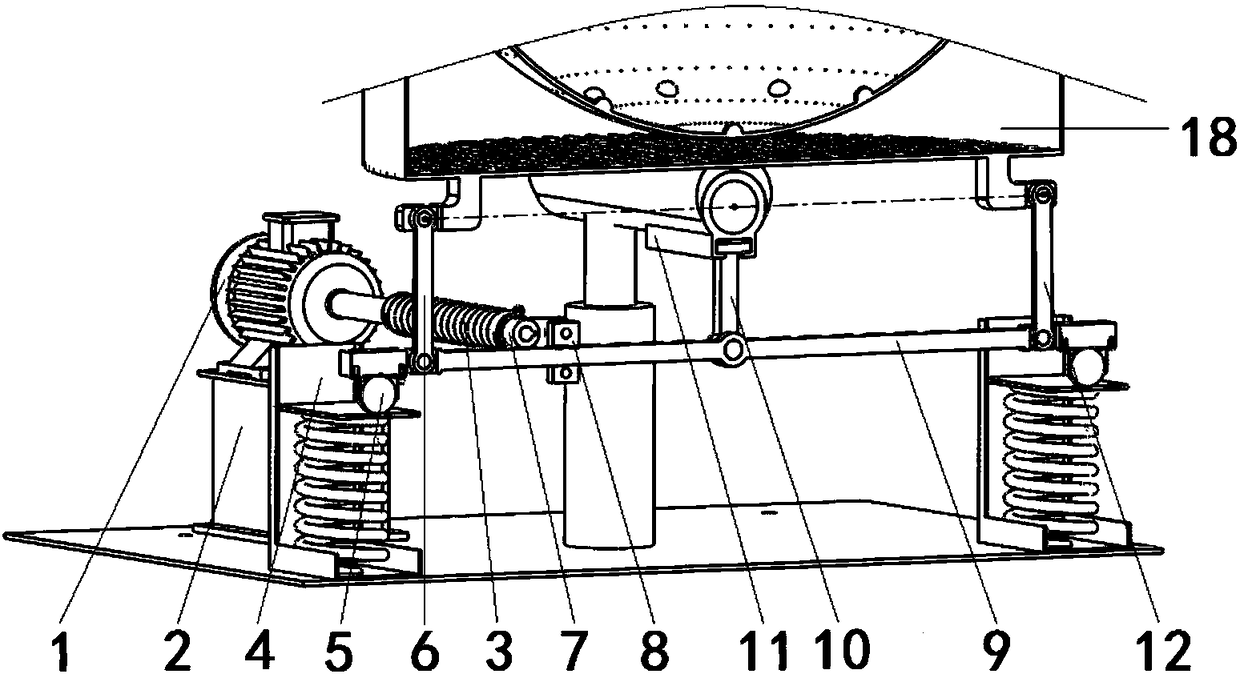

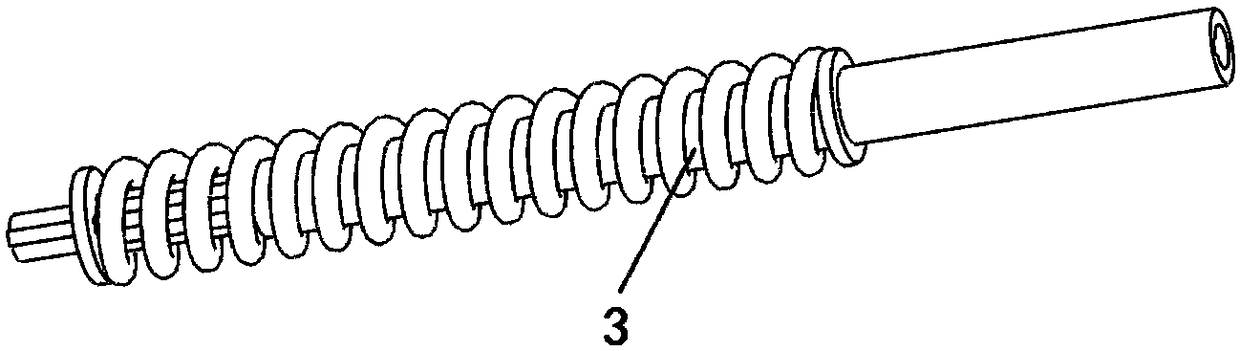

[0027] Such as Figure 1-15 As shown, an electric combined vibration type grain grading device is composed of a rear-end frequency conversion motor 1, a rear-end motor seat 2, a transmission shaft 3, a spring sliding support 4, a universal roller 5, a left connecting rod 6, a rear crank 7, Slider 8, connecting rod 9, lower connecting piece 10, base 11, right connecting rod 12, front-end variable frequency motor 13, front-end motor seat 14, front crank 15, front connecting rod 16, front connecting piece 17, grain bin 18, etc. composition. Wherein rear crank 7, slide block 8, connecting frame rod 9, lower end connector 10 etc. form a swing guide rod mechanism. This mechanism swings back and forth around the hinge point between the connecting frame rod 9 and the lower end connecting piece 10 through the drive shaft 3 and driven by the rear-end variable frequency motor 1; at the same time, through the left connecting rod 6 and right connecting rod 12, the grain bin 18 around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com