A method for manufacturing light-weight and high-strength bionic insect wings

A manufacturing method and high-strength technology, applied in the direction of helicopters, ground equipment, aircraft parts, etc., can solve the problems of high strength and light weight, poor splicing and bonding, and low strength, so as to improve work efficiency and The effect of processing precision, short preparation cycle and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

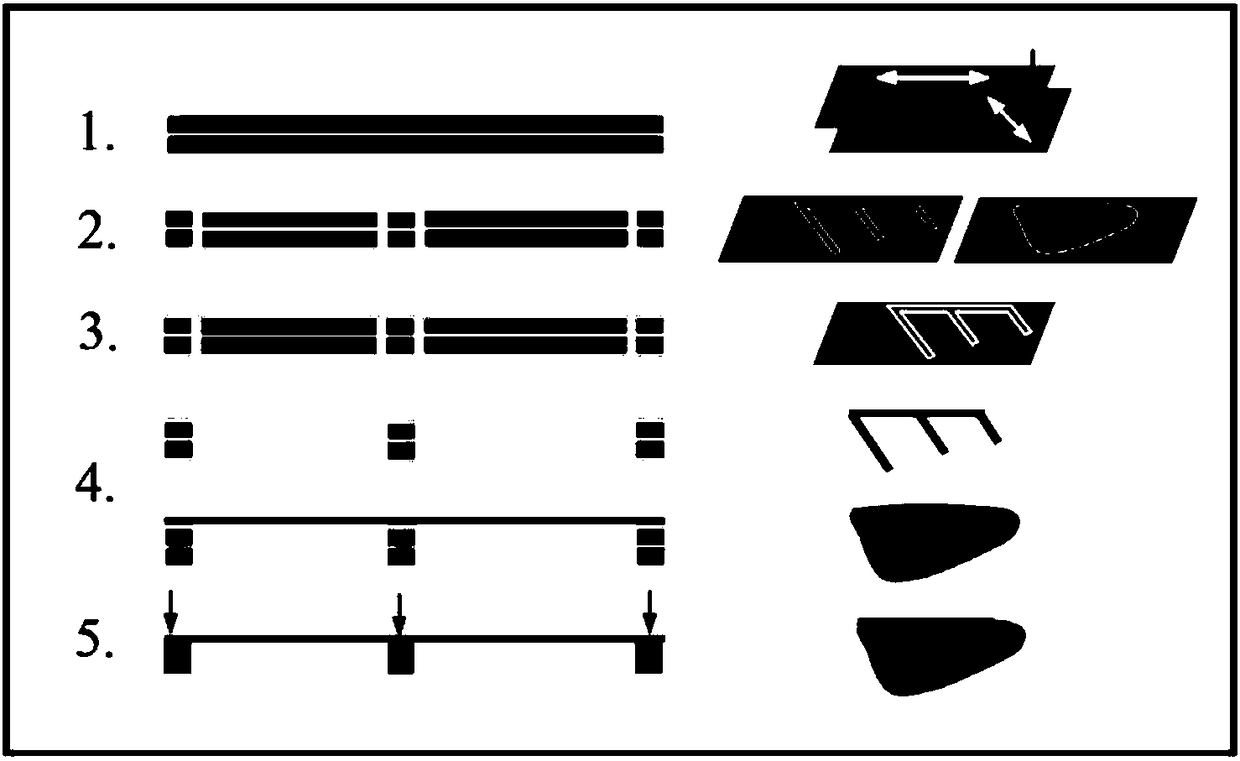

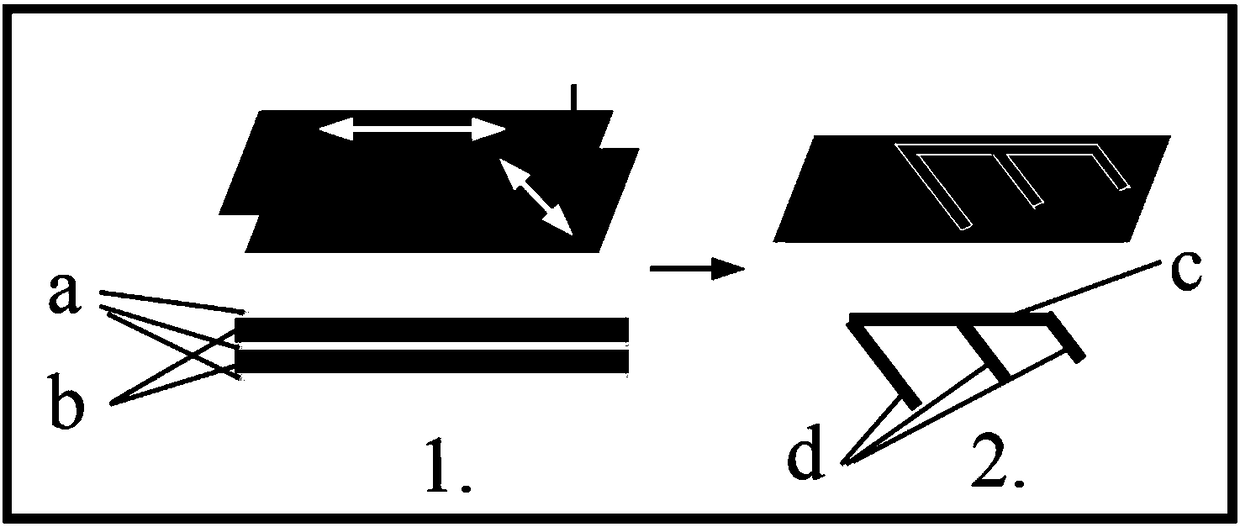

[0031] Such as figure 1 As shown, the present invention provides an implementation example based on a manufacturing method of a light-weight and high-strength bionic insect wing, and the process flow includes:

[0032] 1. Stack and press two pieces of unidirectional carbon fiber prepregs with fiber directions at a certain angle. Among them, the direction of one layer of carbon fiber is the direction of the spar, and the direction of the other layer of carbon fiber is the direction of the rib (in this embodiment example , the thickness of the single-layer carbon fiber prepreg is 30 μm, the content of carbon fiber in the prepreg is 48%, and the two layers of carbon fiber prepreg fibers are stacked and compacted at an angle of 60°);

[0033] 2. Use mechanical drawing to design the shape of the wing support skeleton and the shape of the wing surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com