Three-dimensional model surface treatment device based on ultrasonic waves

A technology for a surface treatment device and a three-dimensional model, which is applied in the field of ultrasonic-based three-dimensional model surface treatment devices, can solve problems such as increasing the polishing time of objects, reducing work efficiency, explosion, etc., achieving automation, safety and reliability, improving use safety, The effect of reducing the polishing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

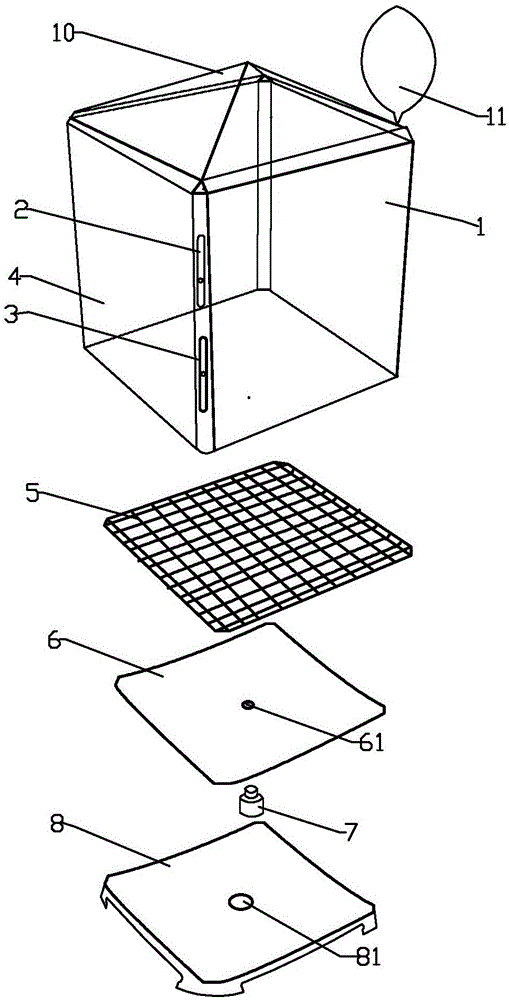

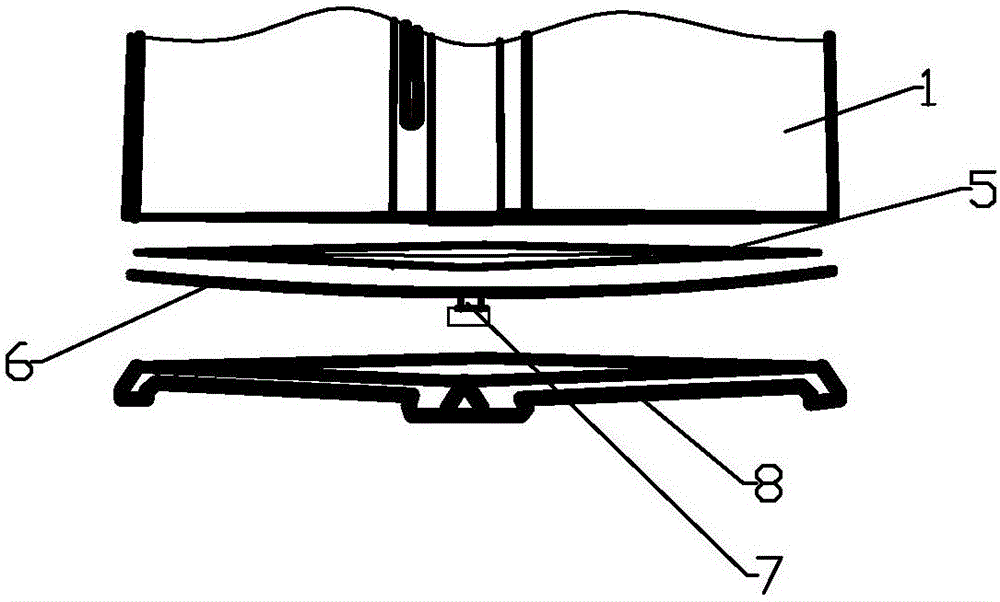

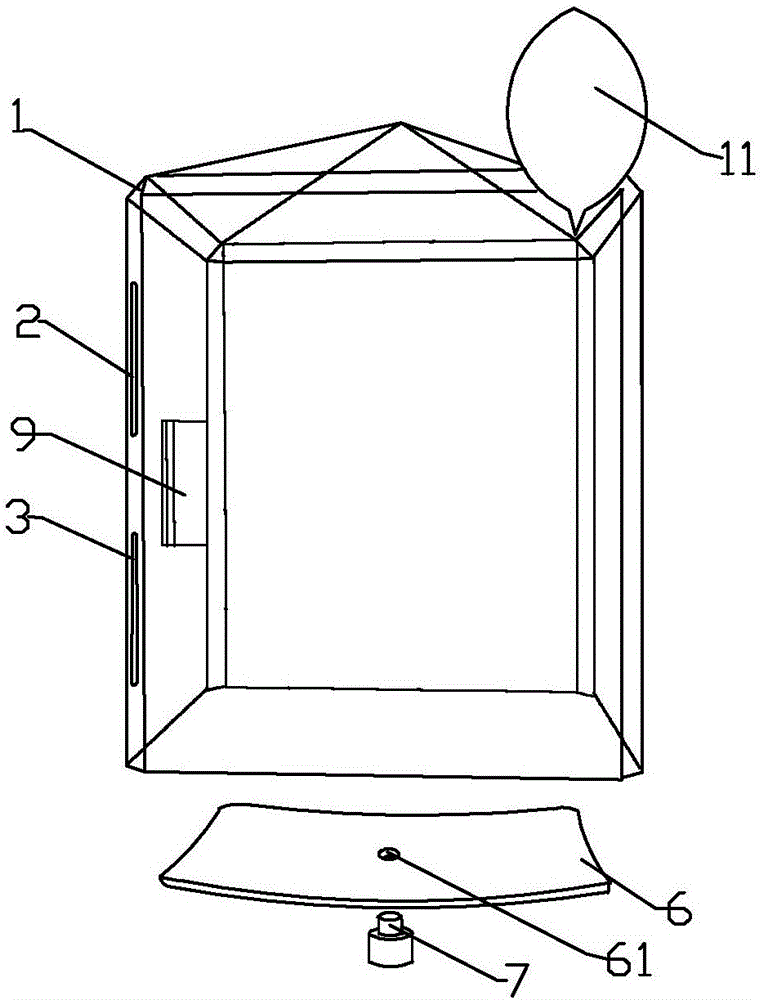

[0019] Such as figure 1 Shown, the specific embodiment of the present invention main body is a box body 1 of a cuboid, and the top of box body 1 has opening and is sealed and fixed with the top cover 10 of pyramid shape, and the bottom of box body 1 is opening design equally, and a base 8 Sealed detachable fixed connection. The central arc surface of the base 8 is concave, and an arc liquid medicine collector 6 is placed on the concave arc surface. The arc-shaped liquid medicine collector 6 is an arc-shaped sheet with a concave center, and a hole 61 is opened in the center thereof. The ultrasonic nebulizer 7 is arranged at the bottom of the arc-shaped liquid medicine collector 6, and the liquid inlet of the ultrasonic atomizer 7 is aligned with the opening 61 in the center of the arc-shaped liquid medicine collector 6 to receive the arc-shaped liquid medicine collection. The medicinal liquid collected in device 6. The liquid medicine returns to the ultrasonic nebulizer 7 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com