Wall reinforcement passing method and reinforcement passing tool for prefabricated construction of block buildings

A reinforcing bar-piercing tool and bar-piercing technology, which are applied in construction, building structure, and building material processing, can solve the problems of low construction efficiency, long time-consuming bar-piercing, complicated bar-piercing operations, etc. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

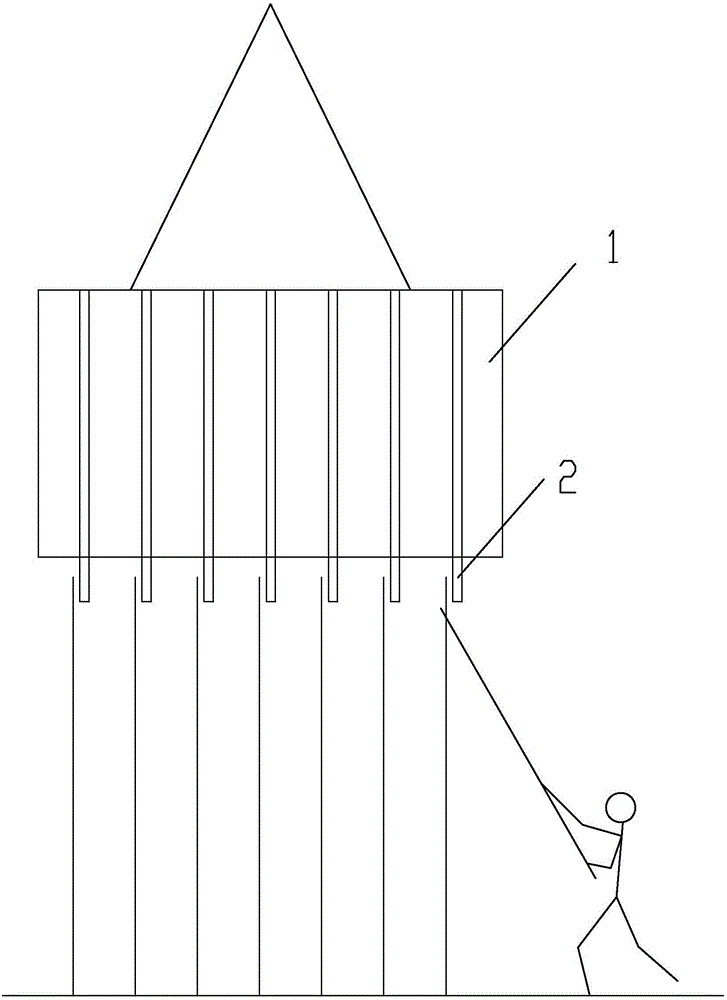

[0027] Specific embodiment one: combine 1 to Figure 6 Illustrate this embodiment, a method for threading reinforcement of a block building assembled construction wall piece in this embodiment, it includes the following steps:

[0028] Step 1: Preparatory work before threading the reinforcement: hang the wall piece 1 directly above the design position of the floor, so that the reinforcement guide pipe 2 overlaps with the reinforcement 3;

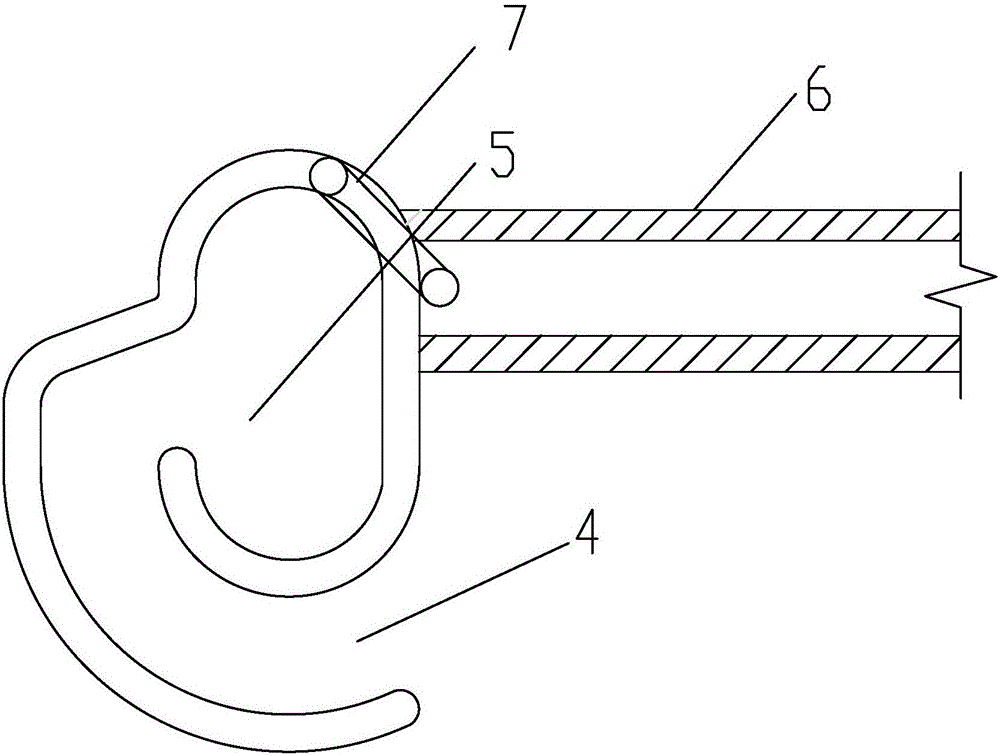

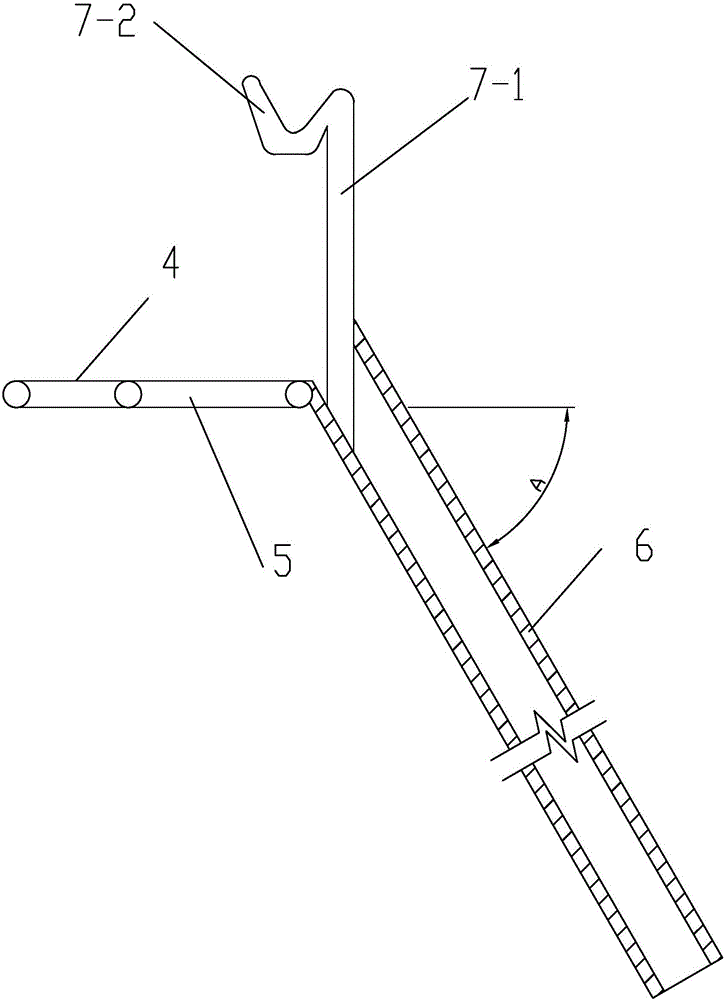

[0029] Step 2: Thread the steel bar 3 in the bar threading tool: at a height that is easy to operate, slide the vertical steel bar 3 into the bar limit ring 5 along the in-out slideway 4 of the bar threading tool;

[0030] Step 3: Alignment of the bar threading tool with the steel bar guide tube 2: move the bar threading tool upward along the length direction of the vertically set steel bar, and move the bar to the position of the steel bar guide tube 2 with the handle 6;

[0031] Step 4: The support of the cantilever frame 7 to the steel b...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination image 3 and Figure 6 To illustrate this embodiment, in the first step of this embodiment, the steel bar guide pipe 2 and the vertical steel bar 3 are partially overlapped by 13cm-18cm. In the actual operation process, the preferred overlapping size is 15cm. With such arrangement, when the operator rotates the grip bar, the steel bar and the bar piercing tool move relatively in the plane, and when the two overlap, the conditions for enclosing the guide tube with the steel bar are met. The overlapping length of the guide tube and the steel bar ensures that the steel bar will not come out of the guide tube. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: combination Figure 1 to Figure 6 Illustrate this embodiment, a method for threading reinforcement of a block building assembled construction wall piece in this embodiment, it includes the following steps:

[0036] Step 1: Preparatory work before threading the reinforcement: hang the wall piece 1 directly above the design position of the floor, so that the reinforcement guide pipe 2 overlaps with the reinforcement 3;

[0037] Step 2: Thread the steel bar 3 in the bar threading tool: at a height that is easy to operate, slide the vertical steel bar 3 into the bar limit ring 5 along the in-out slideway 4 of the bar threading tool;

[0038] Step 3: Alignment of the bar threading tool with the steel bar guide tube 2: move the bar threading tool upward along the length direction of the vertically set steel bar, and move the bar to the position of the steel bar guide tube 2 with the handle 6;

[0039] Step 4: The support of the cantilever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com