Double-layered hoisting type mechanical garage

A mechanical garage and lifting technology, which is applied in the direction of buildings, building types, buildings, etc. where cars are parked, can solve problems such as difficult to meet parking needs, and achieve high space utilization, reliable and stable operation, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

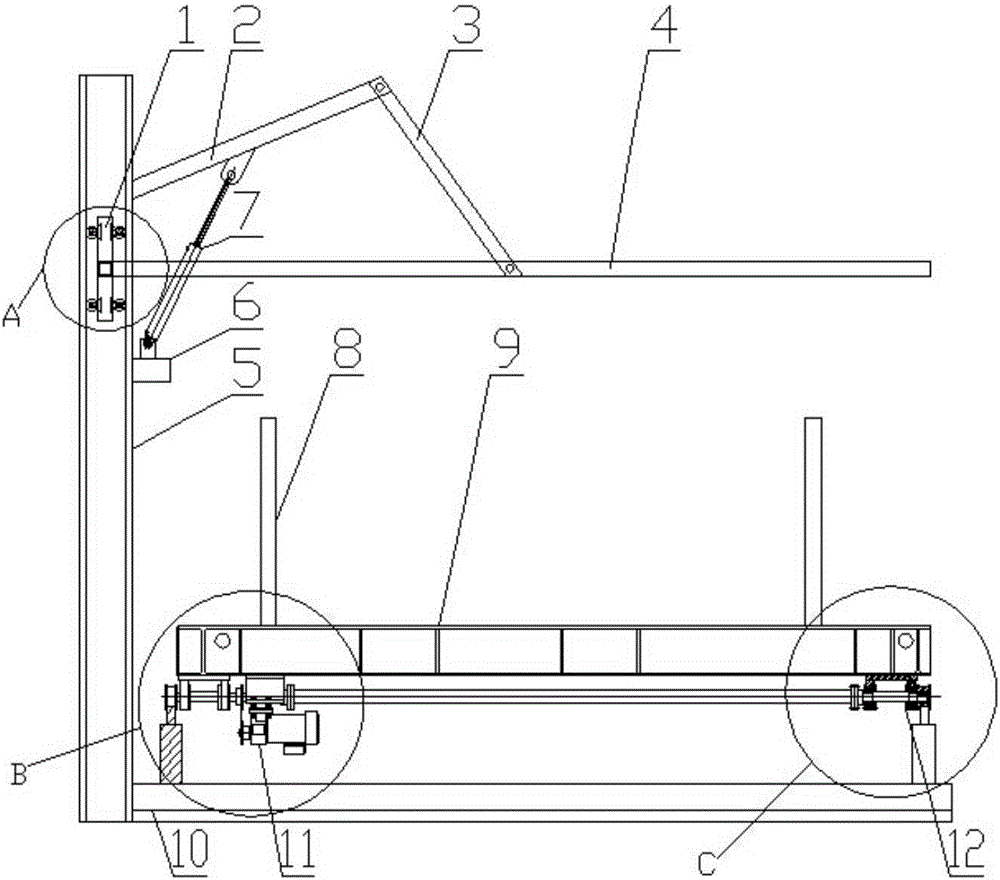

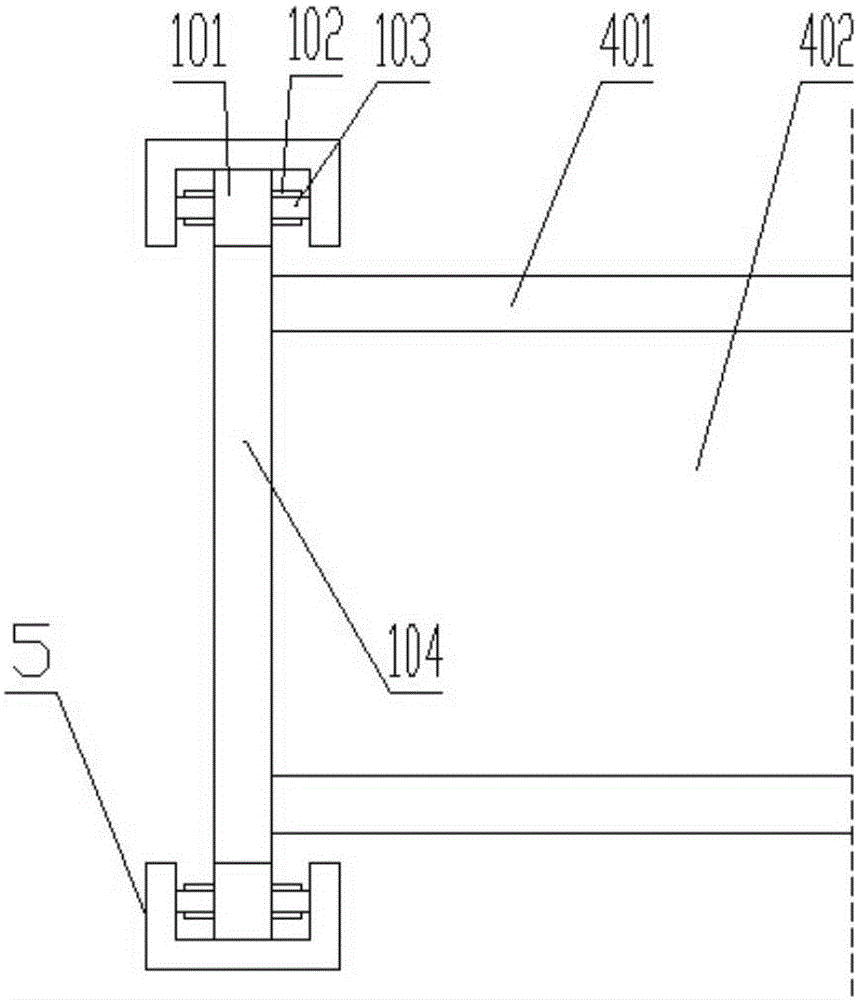

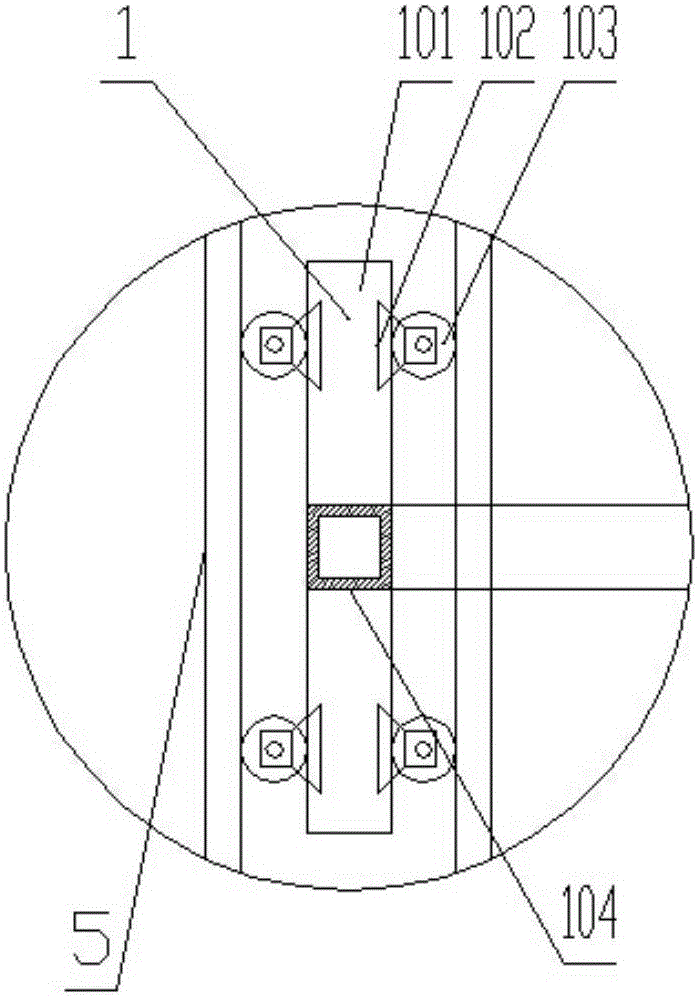

[0025] When parking the car, at first the ground vehicle platform 9 is fully parked, and after the ground vehicle platform 9 is fully parked, the small sprocket 1108 rotates with the driving motor 1109, and the small sprocket 1108 drives the large sprocket 1105 to rotate through the chain, and the large sprocket 1105 and horizontal roller 1101 are all installed on the driven shaft 1104, large sprocket 1105 and horizontal roller 1101 rotate simultaneously, ground vehicle-carrying platform 9 is removed from the bottom of empty vehicle-carrying platform 4, and the piston rod of hydraulic cylinder 7 moves toward Inner contraction, the connecting part of the rocker arm 2 and the lifting arm 3 moves downward, the lifting arm 3 drives the vehicle loading platform 4 to move downward, the owner parks the car on the vehicle loading platform 4, and after the owner leaves the car and the vehicle loading platform 4, The piston rod of the hydraulic cylinder 7 is ejected outwards, and the con...

Embodiment 2

[0027] When picking up the car, if the vehicle to be taken is parked on the ground vehicle platform 9, the car owner can directly drive the car away; The wheel 1108 drives the large sprocket 1105 to rotate through the chain, the large sprocket 1105 and the horizontal roller 1101 are all installed on the driven shaft 1104, the large sprocket 1105 and the horizontal roller 1101 rotate simultaneously, and the ground vehicle platform 9 is parked from the vehicle to be taken. The lower part of the vehicle-carrying platform 4 is moved away, the piston rod of the hydraulic cylinder 7 shrinks inwardly, the connecting part of the rocker arm 2 and the lifting arm 3 moves downward, and the lifting arm 3 drives the vehicle-carrying platform 4 to move downward until the vehicle-carrying platform 4 is moved downward. The platform 4 is parked on the ground, and after the owner drives away the vehicle to be picked up, the piston rod of the hydraulic cylinder 7 is pushed out, and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com