Apparatus for reducing oil leakage in two-stage turbocharger

A turbocharger and supercharger technology, which is applied in the lubrication of turbine/propulsion devices, gas turbine devices, engines, etc., and can solve problems such as lubricating oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An apparatus for reducing lubricant oil leakage in a two-stage turbocharger according to an exemplary embodiment of the present invention, an example of which is shown in the accompanying drawings, will now be described in more detail. Also, the same reference numerals will be used throughout the drawings and specification to refer to the same or like parts.

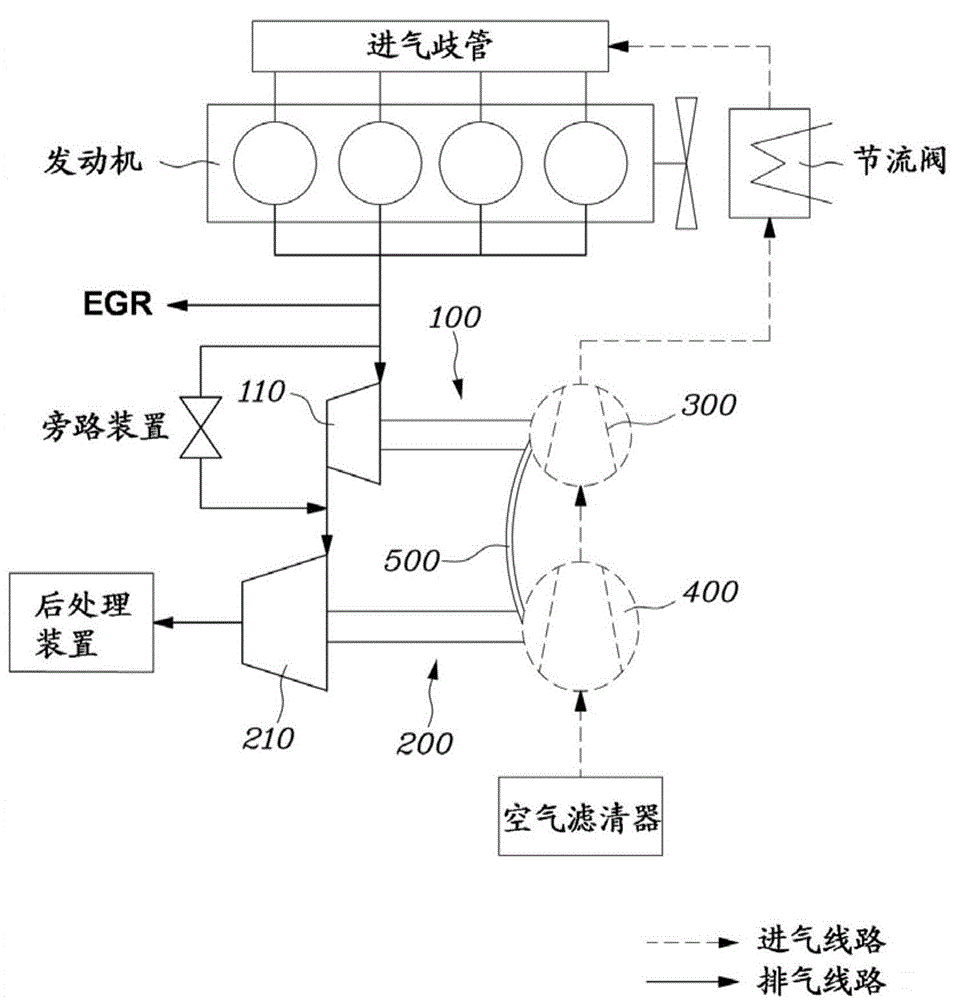

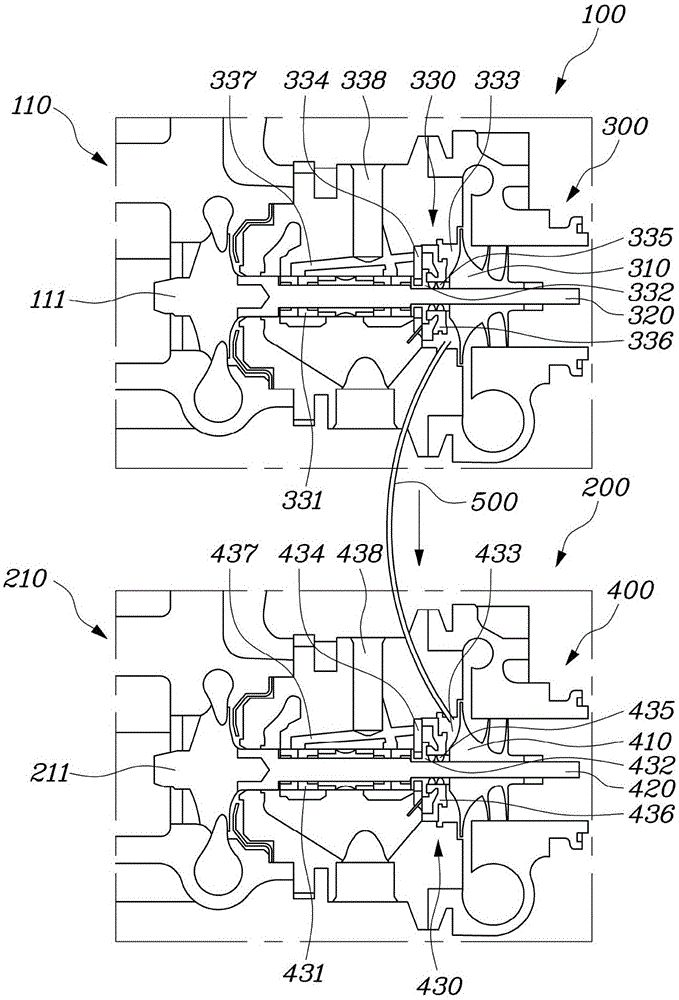

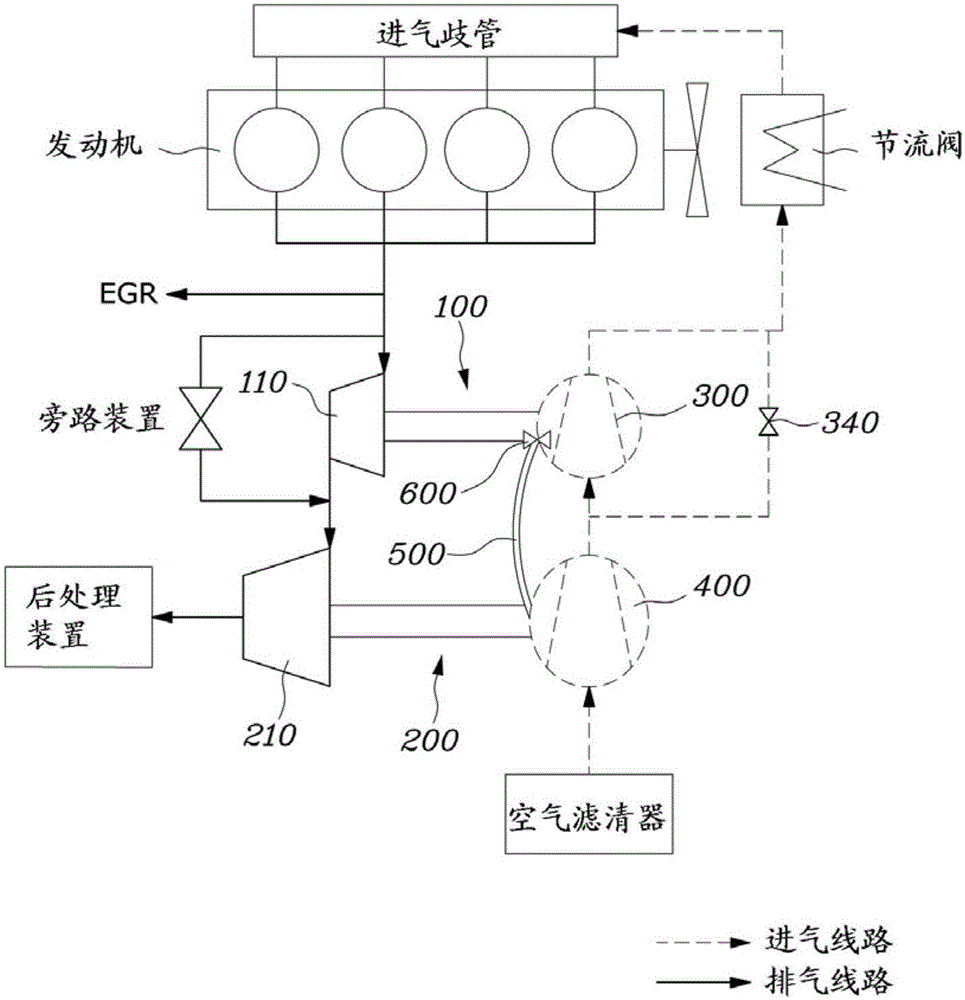

[0017] figure 1 To show a schematic structural view of an exemplary embodiment of an apparatus for reducing lubricating oil leakage in a two-stage turbocharger according to the present invention, figure 2 for figure 1 A detailed view of the transmission side of the middle.

[0018] The apparatus for reducing lubricating oil leakage in a two-stage turbocharger according to the present embodiment includes a transmission part 500 connecting the high-pressure turbocharger 100 to the low-pressure turbocharger 200 so that clean air ( Pressurized air between the back of the compressor wheel and the bearing housing ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com