Spiral grain type solid-liquid rocket engine

A solid-liquid rocket and engine technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low burning rate of solid-liquid rocket engines, and achieve the effects of easy processing, increased burning rate, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] Below in conjunction with accompanying drawing this patent is described further.

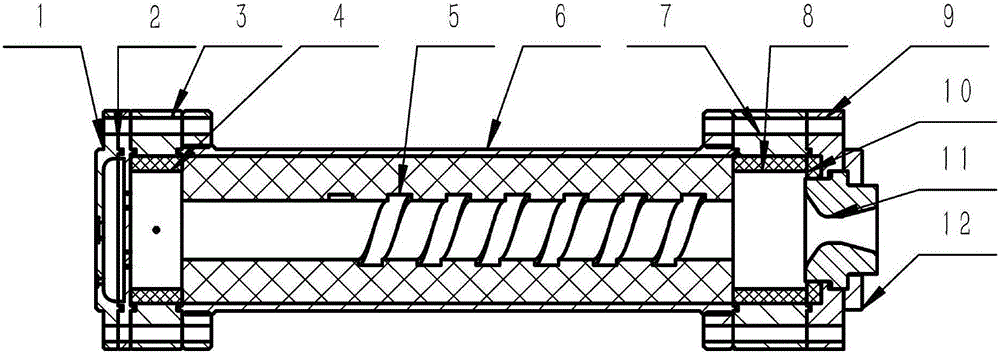

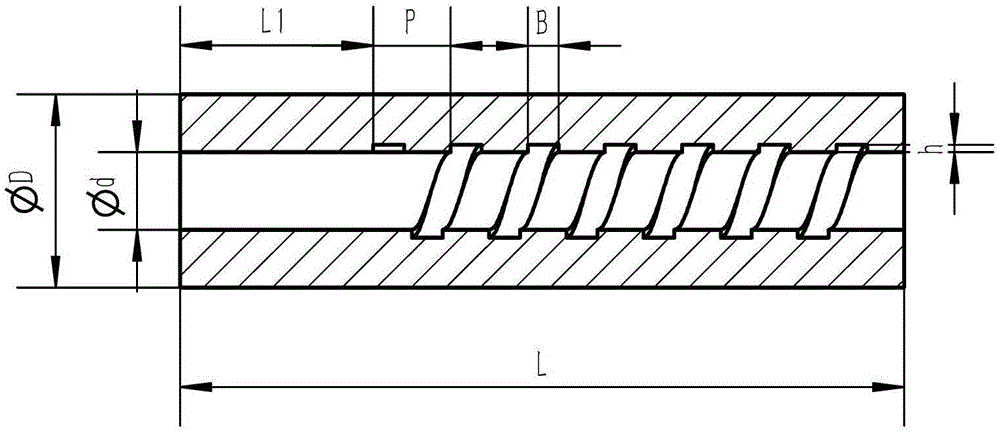

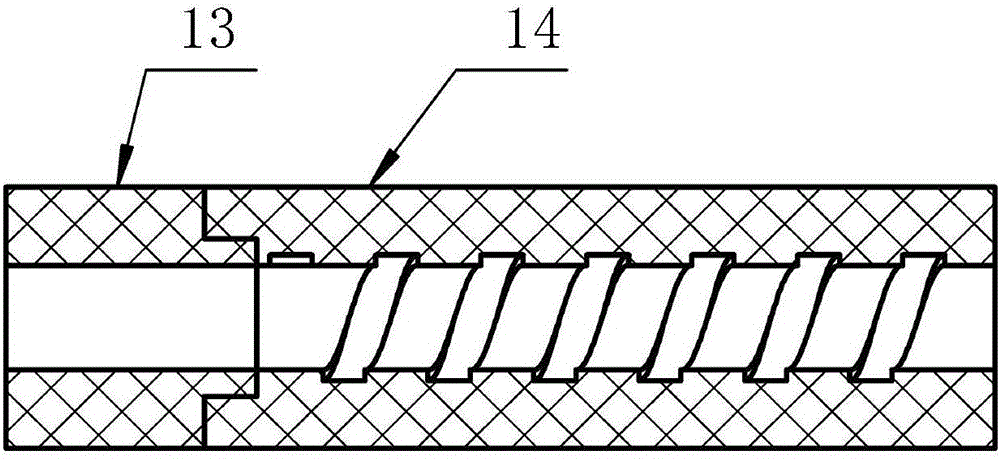

[0023] The patented spiral drug-type solid-liquid rocket engine of the present invention includes a head cover 1, an injection panel 2, a front combustion chamber casing 3, a front combustion chamber insulation layer 4, a charge column 5, a combustion chamber casing 6, and a rear combustion chamber casing 7. After combustion chamber heat insulation layer 8, rear head shell 9, rear head heat insulation layer 10, nozzle 11 and nozzle pressure plate 12, such as figure 1 shown.

[0024] The head cover 1, the injection panel 2, the front combustion chamber housing 3, the combustion chamber housing 6, the rear combustion chamber housing 7, and the rear head housing 9 are all made of stainless steel 1Cr18Ni9Ti material, and from front to back Set coaxially, pass through the head cover 1, the injection panel 2, and the outer edge of the front combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com