Gap sealing structure and bearing

A sealing structure and gap technology, applied in the field of thrust bearings, can solve the problems of no way to reduce the friction force of thrust bearings, can not completely prevent air infiltration, can not save electric energy for a long time, etc., to achieve large axial force, radial stability, low noise small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

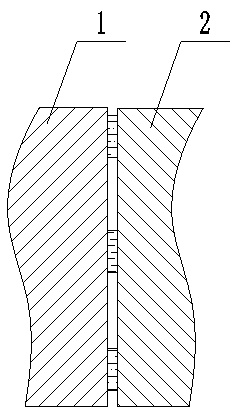

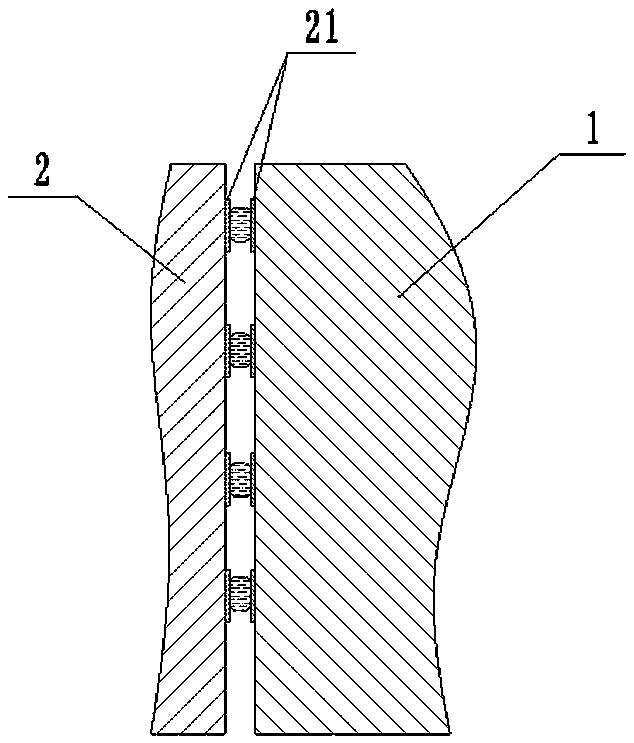

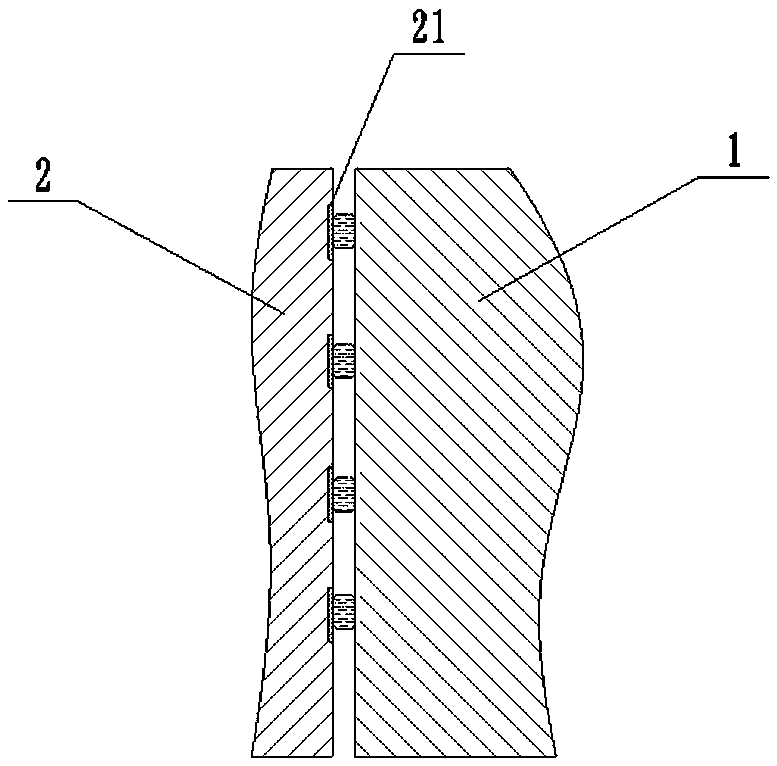

[0047] like figure 1 The gap sealing structure shown includes: a fluid and a holding structure, the fluid forms at least one gap seal in the gap between the walls of the moving body 1 and the static body 2 to be sealed; the holding structure is arranged on one of the moving body 1 and the static body 2 One or two walls are used to keep the fluid in the predetermined sealing position, restrict the movement of the fluid and form a fluid sealing ring between the walls.

[0048] On this basis, the present invention further utilizes the relationship betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com