Cam-type hydraulic polishing machine

A grinding machine, cam type technology, applied in the direction of grinding frame, grinding machine parts, grinding/polishing equipment, etc. The quality and efficiency of polishing can achieve the effect of small pressure loss, stable axial force and less heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

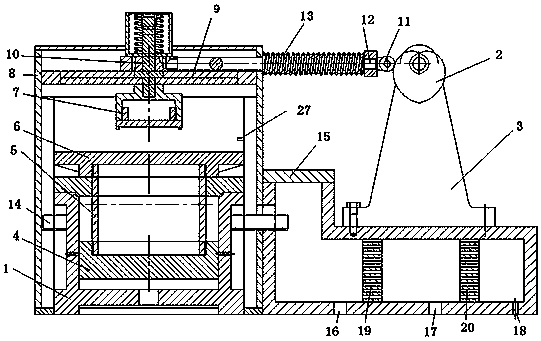

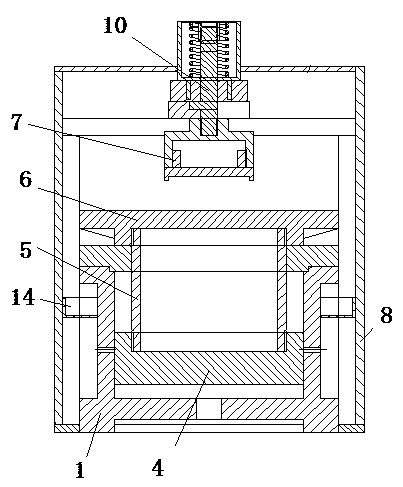

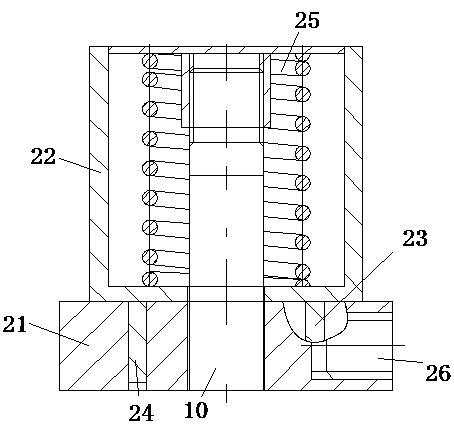

[0016] The technical solutions in the embodiments of the present invention are described in detail below with reference to the drawings in the embodiments of the present invention. The embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

[0017] like figure 1 and figure 2 As shown, a kind of cam type metallographic polishing machine provided by this embodiment includes a frame 8, a piston cylinder 1 is arranged inside the frame 8, and a driving cam 2 is arranged outside the frame 8, and the driving cam 2 is arranged on the outside of the frame 8. The cam 2 is fixed on the cam bracket 3, and a roller 11 is arranged on one side of the driving cam 2, and the roller 11 is installed on a roller pole 12, and a second wheel pole 12 is arranged between the roller pole 12 and the frame 8. A spring 13, the first spring 13 is set on the roller rod 12, the piston 4 is installed in the piston cylinder 1, the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com