Double-clutch planetary electric differential mechanism

A dual-clutch and differential technology, applied in transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as limited climbing ability, poor acceleration performance, and poor passing performance, so as to reduce the number of uses and strength , reduce emissions and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

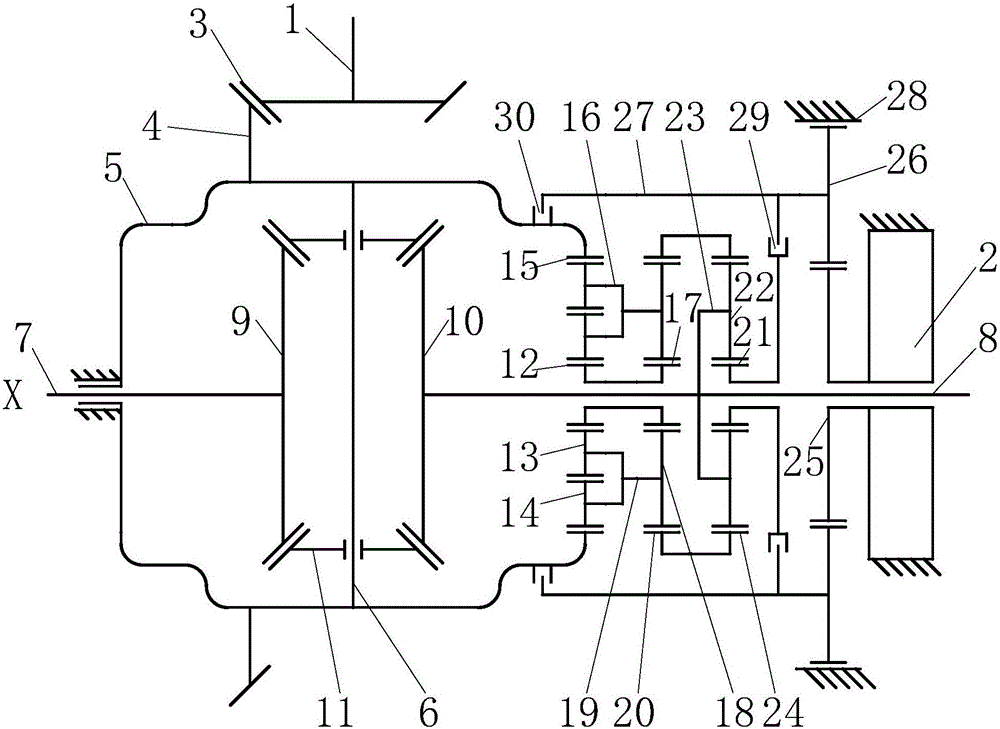

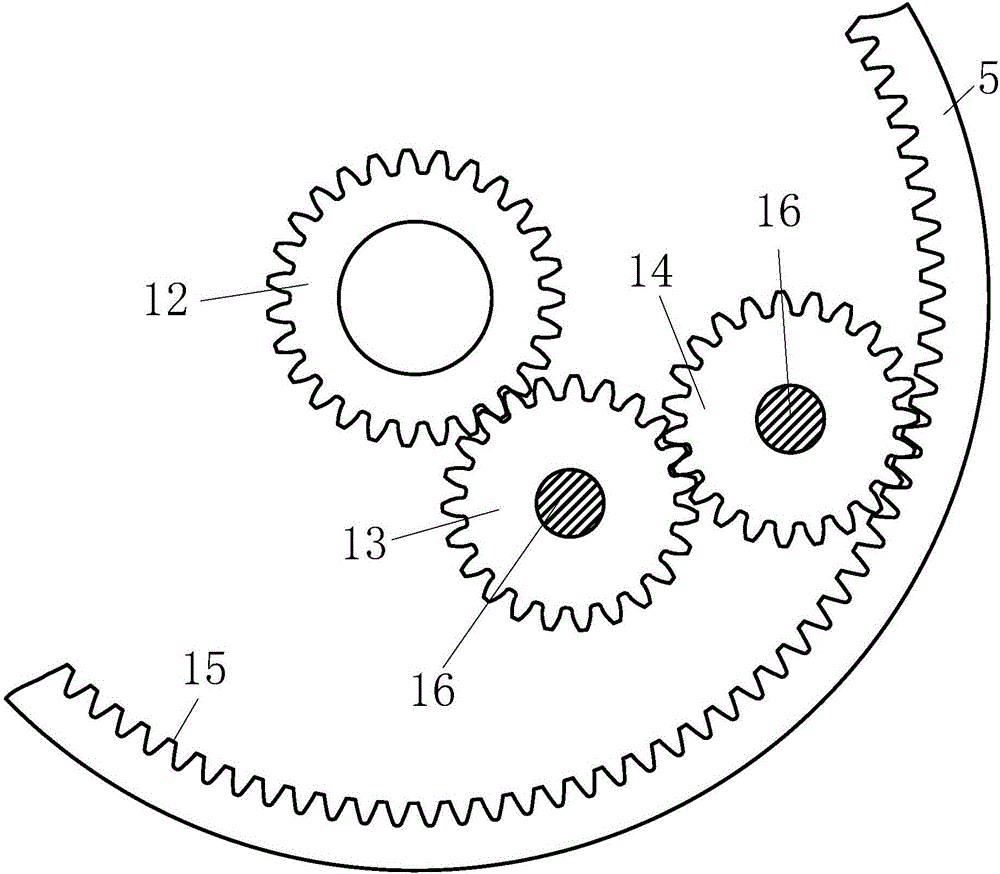

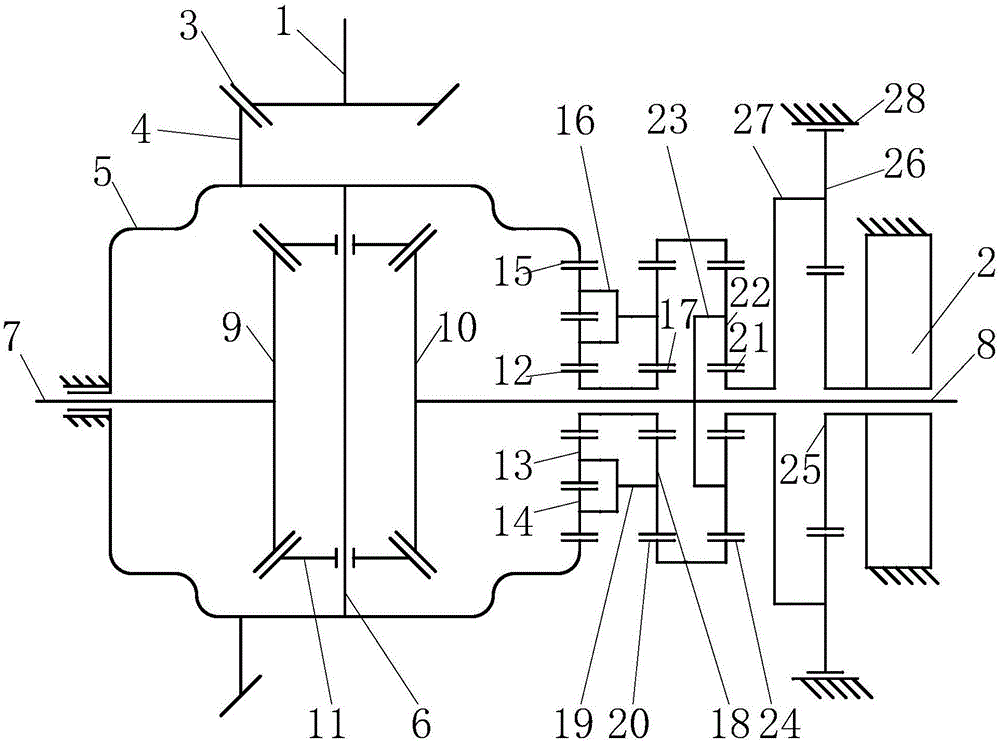

[0036] refer to figure 1 , figure 2 , image 3 , Image 6 , the present invention provides a dual-clutch planetary electric differential. The dual-clutch planetary electric differential mainly includes a main differential, a double planetary gear planetary row, a torque distribution left planetary row, a rotating Torque distribution right planetary row, deceleration planetary row, power clutch, torque distribution clutch and motor.

[0037] refer to figure 1 , image 3 , Image 6 , the main differential includes power input shaft 1, driving bevel gear 3, driven bevel gear 4, differential case 5, planetary gear shaft 6, left half shaft 7, right half shaft 8, left half shaft Bevel gear 9, right side bevel gear 10, planetary bevel gear 11.

[0038] refer to figure 1 , image 3 , Image 6 , the power input shaft 1 and the driving bevel gear 3 have an integral structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com