Solution defrosting and freezing regenerated air source heat pump unit

A technology for regenerating air and solution regeneration, which is applied in the fields of air conditioners, heat pumps, and refrigeration. It can solve the problem of energy loss in defrosting of heat pump units that cannot effectively realize frost-free operation of heat pump units, difficulty in meeting the heat required for solution regeneration, and difficulty in achieving solution regeneration. Temperature requirements and other issues to achieve the effect of improving convenience and flexibility, avoiding energy loss, and solving difficult regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

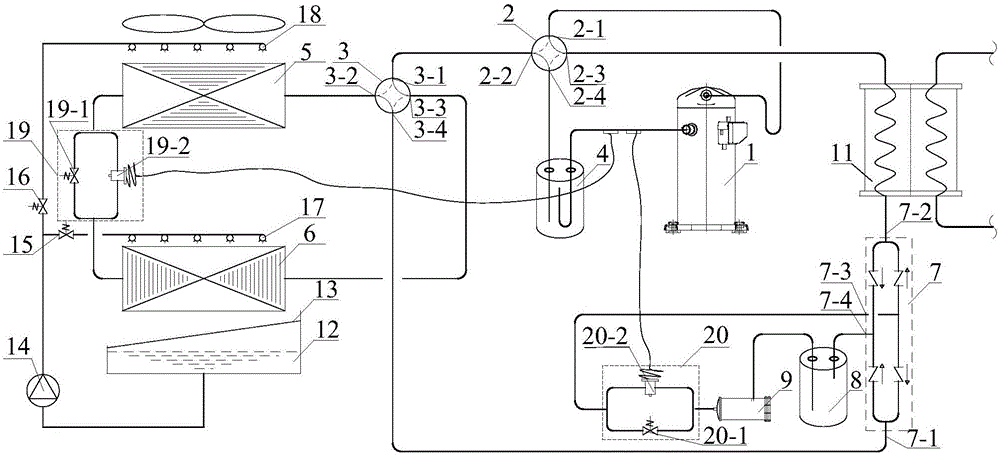

[0020] combine figure 1 , the solution defrosting freezing regeneration air source heat pump unit of the present invention uses the low-temperature refrigerant on the evaporation side to freeze and regenerate the dilute solution after defrosting, and includes a compressor 1 for inhaling gaseous refrigerant and compressing and outputting it. Connecting to reversing valve 2, gas-liquid separator 4, user-side heat exchanger 11, check valve assembly 7, high-pressure liquid reservoir 8, and dry filter 9. The second interface 7-2 of the one-way valve assembly 7 is connected to the outlet of the user-side heat exchanger 11, and the fourth interface 7-4 of the one-way valve assembly 7 is connected to the inlet of the high-pressure accumulator 8, and the high-pressure accumulator 8 is sequentially connected with the dry filter 9 and then connected with the inlet of the second throttle valve assembly 20, and the outlet of the second throttle valve assembly 20 is connected with the third...

Embodiment 2

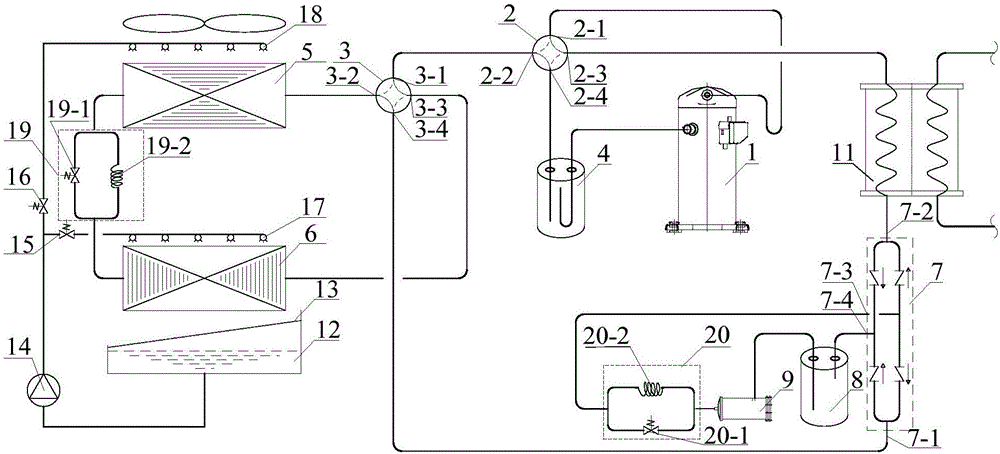

[0040] combine figure 2, the solution defrosting freezing regeneration air source heat pump unit of the present invention uses the low-temperature refrigerant on the evaporation side to freeze and regenerate the dilute solution after defrosting, and includes a compressor 1 for inhaling gaseous refrigerant and compressing and outputting it. Connecting to reversing valve 2, gas-liquid separator 4, user-side heat exchanger 11, check valve assembly 7, high-pressure liquid reservoir 8, and dry filter 9. The second interface 7-2 of the one-way valve assembly 7 is connected to the outlet of the user-side heat exchanger 11, and the fourth interface 7-4 of the one-way valve assembly 7 is connected to the inlet of the high-pressure accumulator 8, and the high-pressure accumulator 8 is sequentially connected with the dry filter 9 and then connected with the inlet of the second throttle valve assembly 20, and the outlet of the second throttle valve assembly 20 is connected with the third...

Embodiment 3

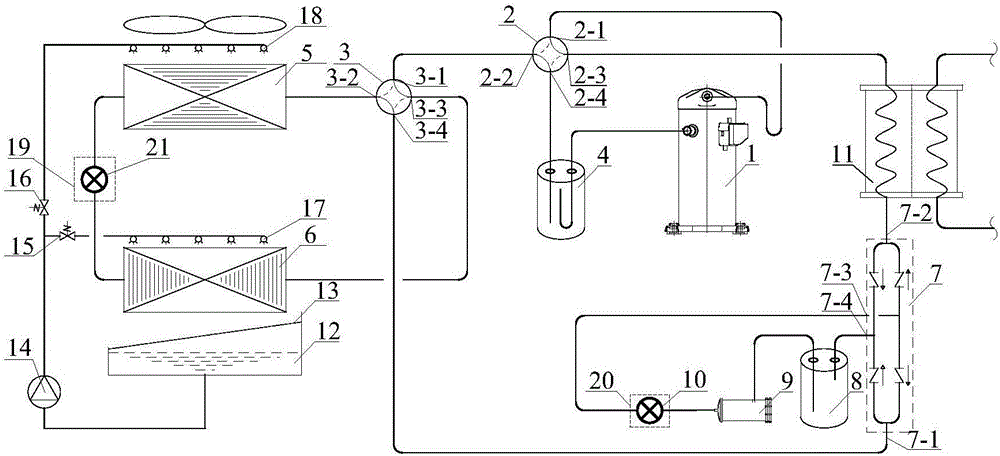

[0044] combine image 3 , the solution defrosting freezing regeneration air source heat pump unit of the present invention uses the low-temperature refrigerant on the evaporation side to freeze and regenerate the dilute solution after defrosting, and includes a compressor 1 for inhaling gaseous refrigerant and compressing and outputting it. Connecting to reversing valve 2, gas-liquid separator 4, user-side heat exchanger 11, check valve assembly 7, high-pressure liquid reservoir 8, and dry filter 9. The second interface 7-2 of the one-way valve assembly 7 is connected to the outlet of the user-side heat exchanger 11, and the fourth interface 7-4 of the one-way valve assembly 7 is connected to the inlet of the high-pressure accumulator 8, and the high-pressure accumulator 8 is sequentially connected with the dry filter 9 and then connected with the inlet of the second throttle valve assembly 20, and the outlet of the second throttle valve assembly 20 is connected with the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com