Flexible sensor and its preparation method

A flexible sensor and flexible insulating material technology, applied in the direction of electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve the problems of complicated, unobtainable, and difficult flexible sensors, etc., with simple and convenient methods, low cost, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The concrete steps of preparation are:

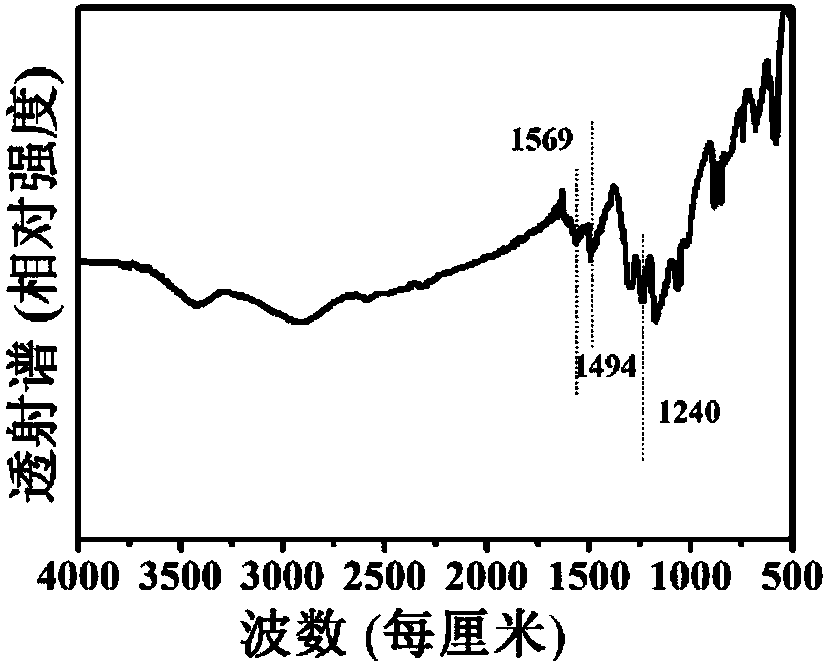

[0045] In step 1, the molar ratio of aniline and protonic acid is 0.8:2.2, and the two are mixed and then stirred evenly to obtain a transparent mixed solution; wherein, the protonic acid is sulfuric acid. Then put the positive electrode and graphite negative electrode in a transparent mixed solution, and the current density is 0.2A / cm 2 After 2 hours of electrodeposition, the following figure 1 Protonic acid-doped polyaniline coated on the positive electrode shown in the spectral line; wherein, the positive electrode is conductive glass.

[0046]Step 2, first bake the protonic acid-doped polyaniline covered on the positive electrode at 50°C for 30 minutes, and then install electrodes on the upper surfaces of both ends; where the electrodes are installed by using conductive silver glue to mix the wire with protonic acid The mixed polyaniline is connected to obtain the protonic acid-doped polyaniline covered on the positive elec...

Embodiment 2

[0048] The concrete steps of preparation are:

[0049] In step 1, the molar ratio of aniline and protonic acid is 0.9:2.1, and the two are mixed and then stirred evenly to obtain a transparent mixed solution; wherein, the protonic acid is sulfuric acid. Then put the positive electrode and graphite negative electrode in a transparent mixed solution, and the current density is 0.4A / cm 2 After 1.7h of electrodeposition, the following figure 1 Protonic acid-doped polyaniline coated on the positive electrode shown in the spectral line; wherein, the positive electrode is conductive glass.

[0050] Step 2, first bake the protonic acid-doped polyaniline covered on the positive electrode at 55°C for 25 minutes, and then install electrodes on the upper surfaces of both ends; wherein, the installation electrode is to use conductive silver glue to mix the wire with protonic acid The mixed polyaniline is connected to obtain the protonic acid-doped polyaniline covered on the positive elec...

Embodiment 3

[0052] The concrete steps of preparation are:

[0053] In step 1, the molar ratio of aniline and protonic acid is 1:2, the two are mixed and then stirred evenly to obtain a transparent mixed solution; wherein the protonic acid is sulfuric acid. Then put the positive electrode and graphite negative electrode in a transparent mixed solution, and the current density is 0.6A / cm 2 After 1.3h of electrodeposition, the following figure 1 Protonic acid-doped polyaniline coated on the positive electrode shown in the spectral line; wherein, the positive electrode is conductive glass.

[0054] Step 2, first bake the protonic acid-doped polyaniline covered on the positive electrode at 60°C for 20 minutes, and then install electrodes on the upper surfaces of both ends; wherein, the installation electrode is to use conductive silver glue to mix the wire with protonic acid The mixed polyaniline is connected to obtain the protonic acid-doped polyaniline covered on the positive electrode wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com