Projector calibration method based on red and blue checkerboard calibration plate

A technology for calibrating plates and projectors, which is applied to instruments, measuring devices, optical devices, etc., can solve the problems of low measurement efficiency, no obvious inhibition of phase error, unavoidable phase error, etc., to achieve uniform reflectivity, improve Phase unwrapping accuracy, the effect of reducing the effects of gamma nonlinearity and ambient noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to describe the technical content of the present invention more clearly, further detailed description will be given below in conjunction with specific embodiments.

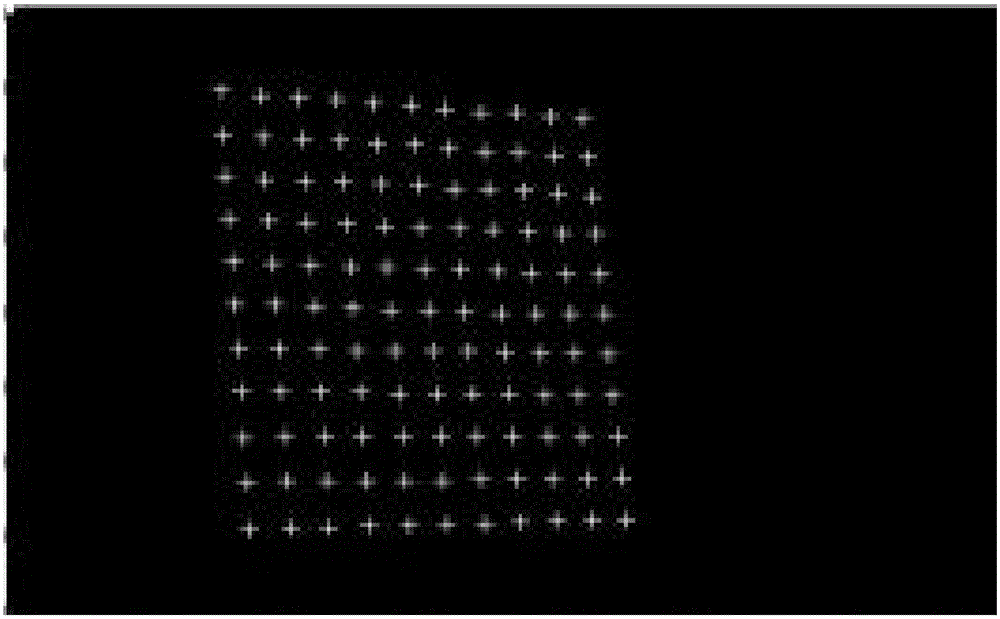

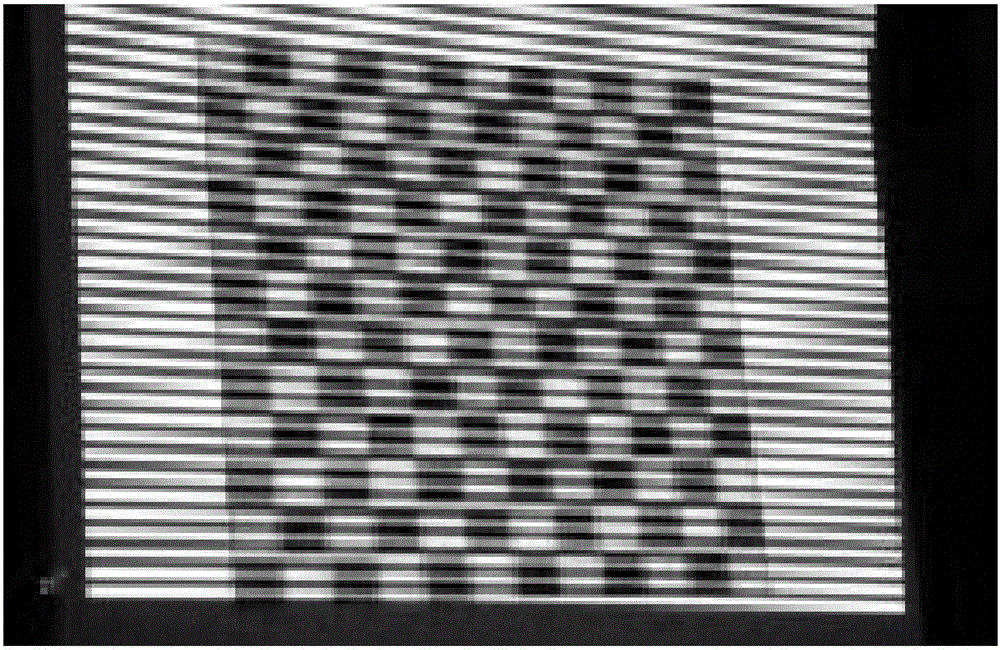

[0069] The calibration principle of the projector calibration method based on the red and blue checkerboard calibration board of the present invention is as follows: the projector is regarded as a reverse camera, and the camera calibration method can be used to calibrate the parameters of the projector. Specifically: the projector projects the vertical and horizontal white sinusoidal phase shift grating stripe images generated by computer software to the plane of the red and blue checkerboard calibration plate, and the camera at a certain angle with the projector acquires the deformed grating stripe images, and Calculate the unwrapped phase in the vertical and horizontal directions separately. Determine the pixel coordinates of the corner points in the projection image according to the unfolded pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com