Quantitative determination method and special device of corrosive sulfur in insulating oil

A corrosive sulfur, quantitative measurement technology, applied in the field of measurement, can solve the problems of shortening the life of electrical equipment such as transformers, affecting the insulation partial discharge performance, affecting the accuracy of test results, etc., to achieve rapid installation, isolation of air effects, and rapid response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Embodiment: a kind of quantitative determination method of corrosive sulfur in insulating oil, it comprises the steps:

[0041] 1. Sample collection:

[0042] Use a special sampler for corrosive sulfur in insulating oil (sampler for short) to collect samples of insulating oil in operation;

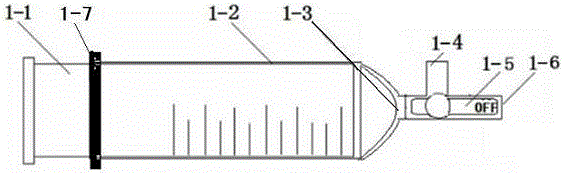

[0043] The described sampler for the analysis of dissolved gas in insulating oil (see figure 1 ) includes a sampler body 1-2, the sampler body 1-2 adopts a combination structure of a cylinder and a hemisphere, the sampler body 1-2 is provided with a push-pull sampler piston 1-1; the hemisphere of the sampler body 1-2 The top of the body is provided with a sample injection quick interface 1-3, and the sample injection quick interface 1-3 is respectively connected to the oil discharge port 1-4 and the sampling port 1-6 through the multi-channel sealing valve 1-5. The end of the sampler body is provided with fastening clips 1-7 that protrude from the plane of the body. The cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com