Method for evaluating performance of monocrystalline high-temperature alloy in special environments

A high-temperature alloy and evaluation method technology, applied in the field of high-temperature alloys, can solve problems such as no available data reference, no special equipment for molding, blank experimental data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

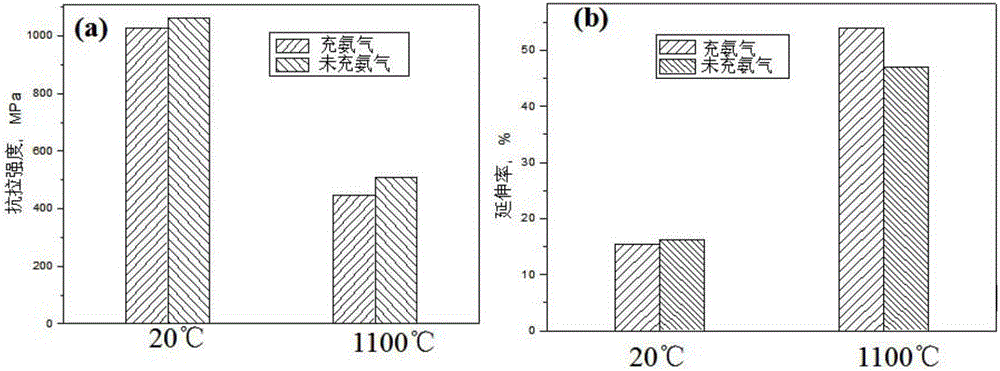

[0020] First, the single crystal superalloy (DD405 alloy) is processed into performance test samples, and the processed performance test samples are placed in the inner tube of the glass tube. After the air in the tube is drawn out, it is filled with ammonia gas at a pressure of 0.02MPa, and then the glass The inner tube of the tube is closed, and the diameter of the inner tube of the glass tube is 13 mm.

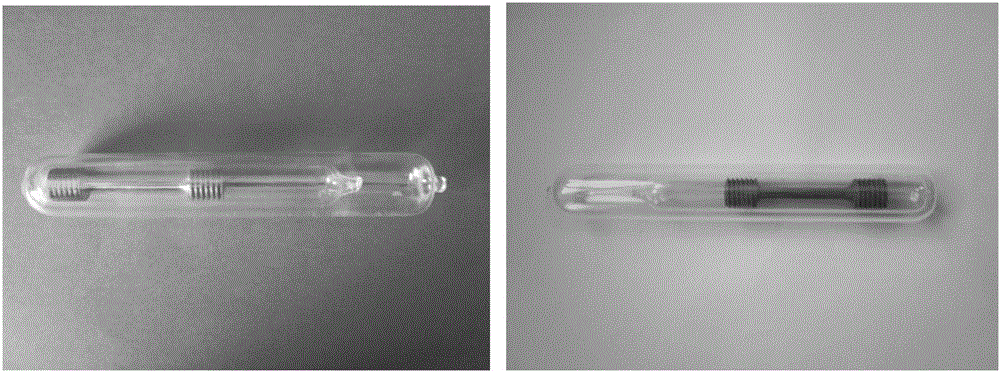

[0021] In order to prevent the glass tube from rupturing in high temperature environment, double-layer glass tube encapsulation is adopted. The inner tube of the first encapsulated glass tube is placed in the outer tube of the larger diameter glass tube (diameter 15mm). After the air in the glass tube sandwich is exhausted, Then fill the ammonia gas with a pressure of 0.02MPa, and then seal the outer tube of the glass tube (such as figure 1 ).

[0022] Place the packaged sample in a high-temperature muffle furnace, raise the temperature to 1000°C, and take out the glass tube aft...

Embodiment 2

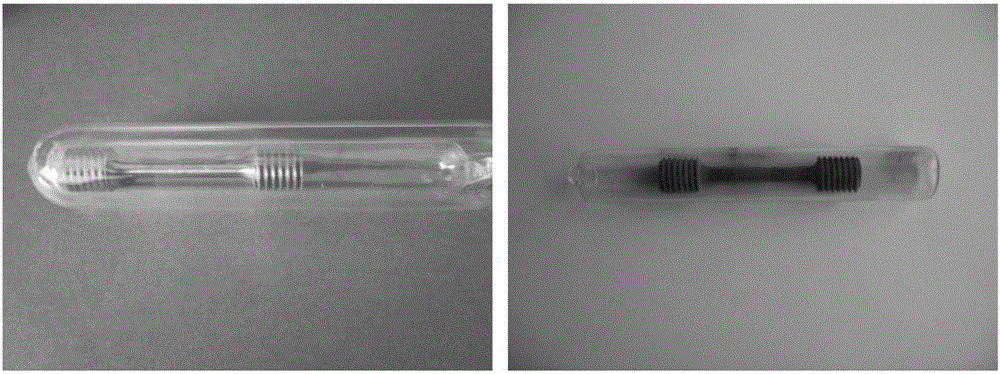

[0025] First, the single crystal superalloy (DD405 alloy) is processed into performance test samples. The processed performance test samples are placed in the inner tube of the glass tube. After the air in the tube is drawn out, it is filled with nitrogen at a pressure of 0.02MPa, and then the glass tube The inner tube of the glass tube is closed, and the diameter of the inner tube of the glass tube is 13mm.

[0026] In order to prevent the glass tube from rupturing in high temperature environment, double-layer glass tube encapsulation is adopted. The inner tube of the first encapsulated glass tube is placed in the outer tube of the larger diameter glass tube (diameter 15mm). After the air in the glass tube sandwich is exhausted, Then fill the ammonia gas with a pressure of 0.02MPa, and then seal the outer tube of the glass tube (such as image 3 ).

[0027] Place the packaged sample in a high-temperature muffle furnace, raise the temperature to 1000°C, and take out the glass tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com