Device for generating rotating hexagonal plasma photonic crystals and method thereof

A plasma and photonic crystal technology, applied in the field of plasma application technology and optics, to achieve the effect of increasing the rotation speed, enriching the modulation, wide application prospects and application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

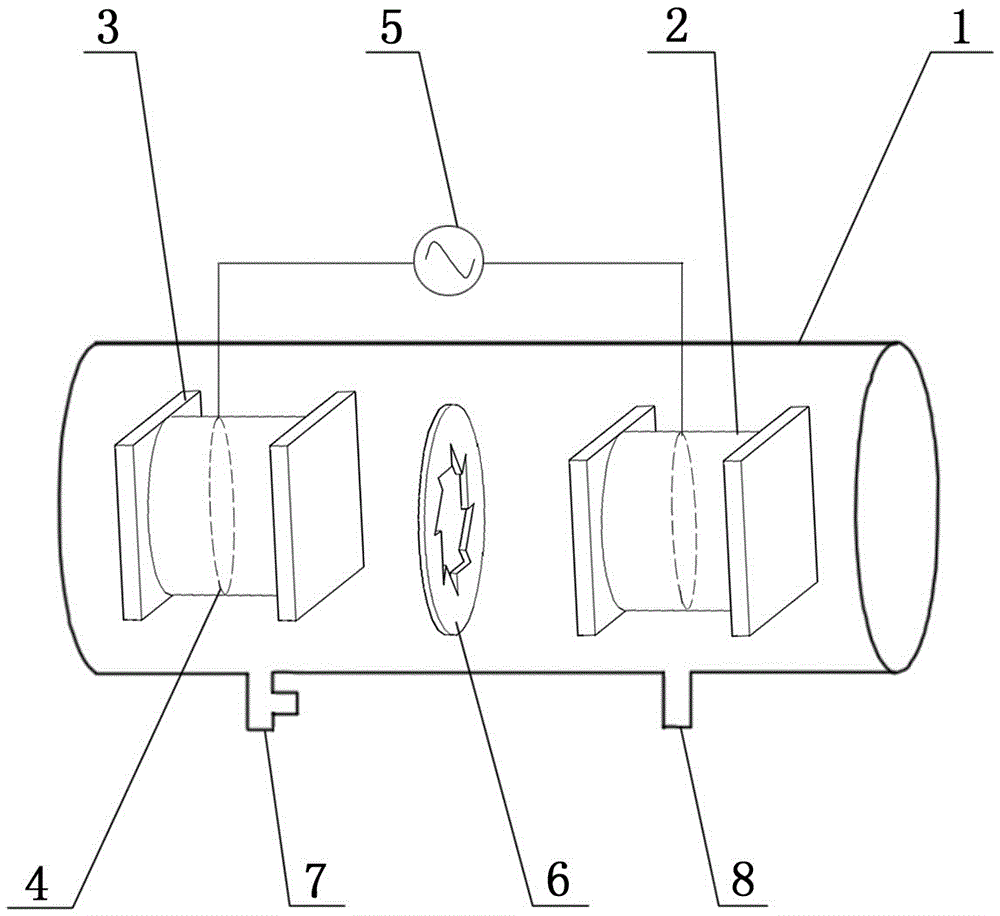

[0030] Such as figure 1 As shown, the device for generating rotating hexagonal plasmonic photonic crystals provided by the present invention is to symmetrically arrange two airtight dielectric containers in a horizontal cylindrical vacuum reaction chamber 1, and inject water into the airtight dielectric containers to form A water electrode 2 with two polar plates facing each other. The two water electrodes 2 are electrically connected with the plasma generating power source 5 outside the vacuum reaction chamber 1 . Water electrode 2 also can adopt plexiglass tube, two ends are sealed with glass baffle 3, is filled with water and built-in copper ring 4, makes two electrodes of plasma generation power supply 5 connect two copper rings 4 by power line respectively. The thickness of the glass block 3 is between 1.5 mm and 5 mm, serving as a discharge medium. A gas inlet 7 and a gas outlet 8 are opened on the wall of the vacuum reaction chamber 1 .

[0031] A frame 6 is arranged...

Embodiment 2

[0035] The method for producing the rotating hexagonal plasmonic photonic crystal provided by the present invention comprises the following steps:

[0036] a. A vacuum reaction chamber 1 is set, an air inlet 7 and an air outlet 8 are provided on the wall of the vacuum reaction chamber 1, and two water electrodes 2 opposite to each other are installed in the vacuum reaction chamber 1 . The water electrode 2 adopts a plexiglass tube sealed with glass baffles 3 on both sides and filled with water, and a built-in copper ring 4 is electrically connected with the plasma generating power supply 5 outside the vacuum reaction chamber 1 .

[0037] b. A frame 6 with a thickness of 2.5mm is arranged between the two water electrodes 2. The frame 6 is made of resin material. The plane where the frame 6 is located is perpendicular to the axes of the two water electrodes 2. The end face of the water electrode 2. The inner edge of frame 6 is to be adjacent to form a circular structure success...

Embodiment 3

[0040] Compared with Embodiment 2, this embodiment differs in that: the pressure of the discharge gas is p=0.7atm.

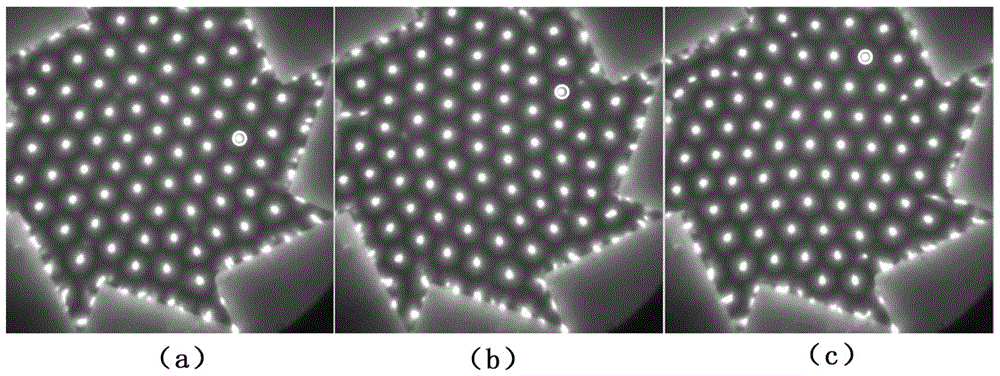

[0041] The photo of the rotating hexagonal plasmonic photonic crystal produced in the discharge gap of the present embodiment is as follows Figure 4 as shown, Figure 4 The three photos in (a), (b), and (c) are also taken every 500ms. The discharge wire marked by the white circle on each photo is the same discharge wire. It can be seen from the change of the position of the discharge wire, The angular velocity of the rotating hexagonal plasmonic photonic crystal generated in this embodiment is about 20° / s, and the rotation direction is consistent with the inclination direction of all ratchets, that is, it rotates along the gentle slope of the ratchet to its steep slope, as shown in the figure Rotate clockwise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com