Laser processing device based on dynamic focusing

A dynamic focusing, laser processing technology, applied in laser welding equipment, metal processing equipment, optics, etc., can solve the problems of low position accuracy and can not meet the needs of high-speed and high-precision scanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

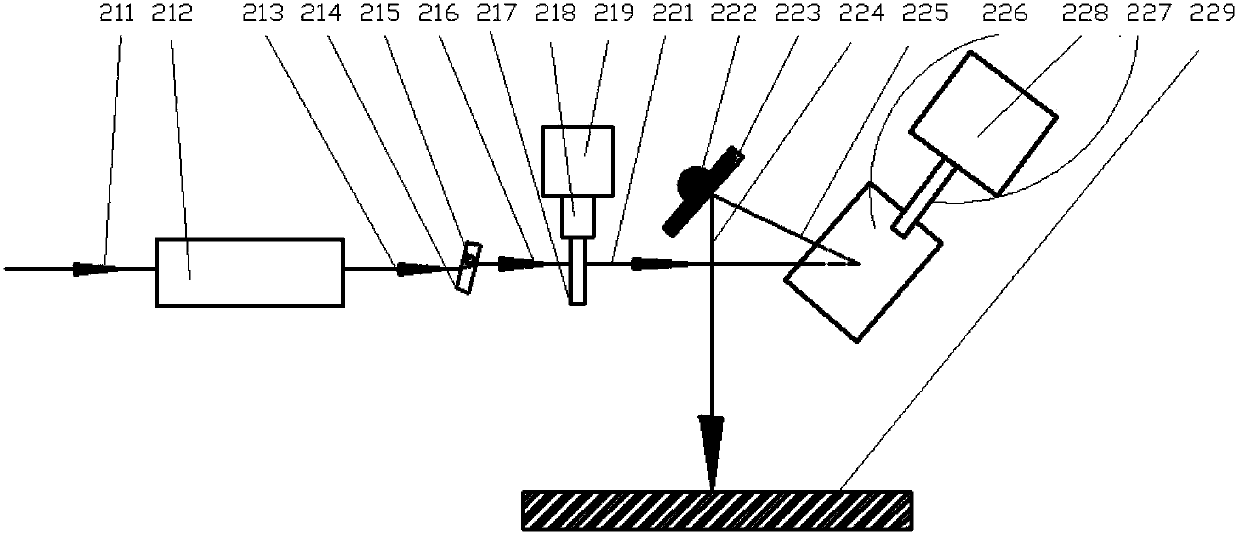

[0043] figure 1 Schematic diagram of the device structure for rapid prototyping of ultraviolet laser photocuring, such as figure 2 Shown: UV laser photocuring rapid prototyping device, including dynamic focusing mirror, beam fine scanning module and large format scanning module.

[0044] The dynamic focusing mirror has a wavelength of 355 nanometers, a central focal length of 1500 mm, and a focusing spot of 100 microns.

[0045] The beam fine scanning module includes two laser beam offset units, namely a first laser beam offset unit and a second laser beam offset unit, the first laser beam offset unit includes a first flat quartz glass 214 and is used to drive the The first motor of the first flat quartz glass 214, the first flat quartz glass 214 is installed on the motor shaft 215 of the first motor, and the axis of the motor shaft 215 of the first motor is perpendicular to the paper. The second laser beam offset unit includes a second flat quartz glass 217 and a second mo...

Embodiment 2

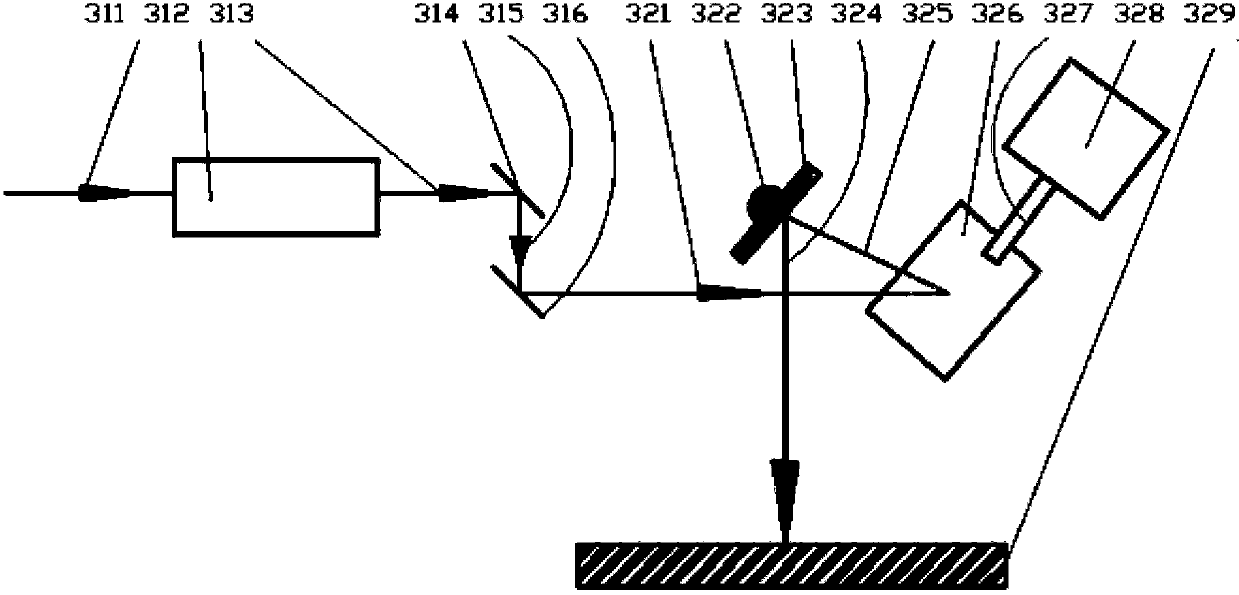

[0057] figure 2 Schematic diagram of the device structure for touch screen ITO film engraving, such as figure 2 Shown: The touch screen ITO film engraving device includes a dynamic focusing mirror, a beam fine scanning module and a large format scanning module.

[0058] The dynamic focusing mirror has a wavelength of 355nm and a central focal length of 1000mm.

[0059] The beam fine scanning module includes two laser beam offset units, namely a first laser beam offset unit and a second laser beam offset unit, the first laser beam offset unit includes a first plane mirror 314 and is used to drive the The first piezoelectric ceramic driving system (not shown in the figure) for the movement (swing or translation) of the first plane mirror 314, the second laser beam offset unit includes a second plane mirror 316 and is used to drive the first plane mirror 316 The second piezoelectric ceramic drive system (not shown in the figure) for the movement (swing or translation) of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com