Device for improving optical orientation of sleeve cutting type panel

一种切面、板光的技术,应用在图纹面的照相制版工艺、用于光机械处理的原件、光学等方向,能够解决碎亮点、液晶扩散不良等问题,达到提高显示质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

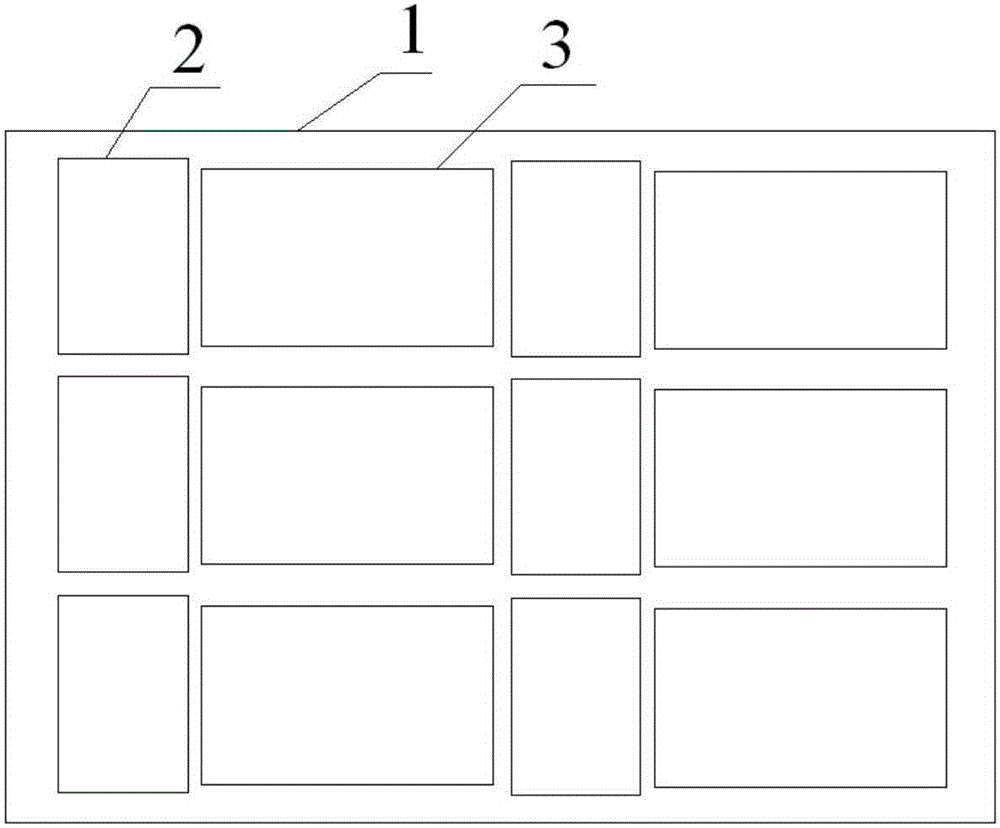

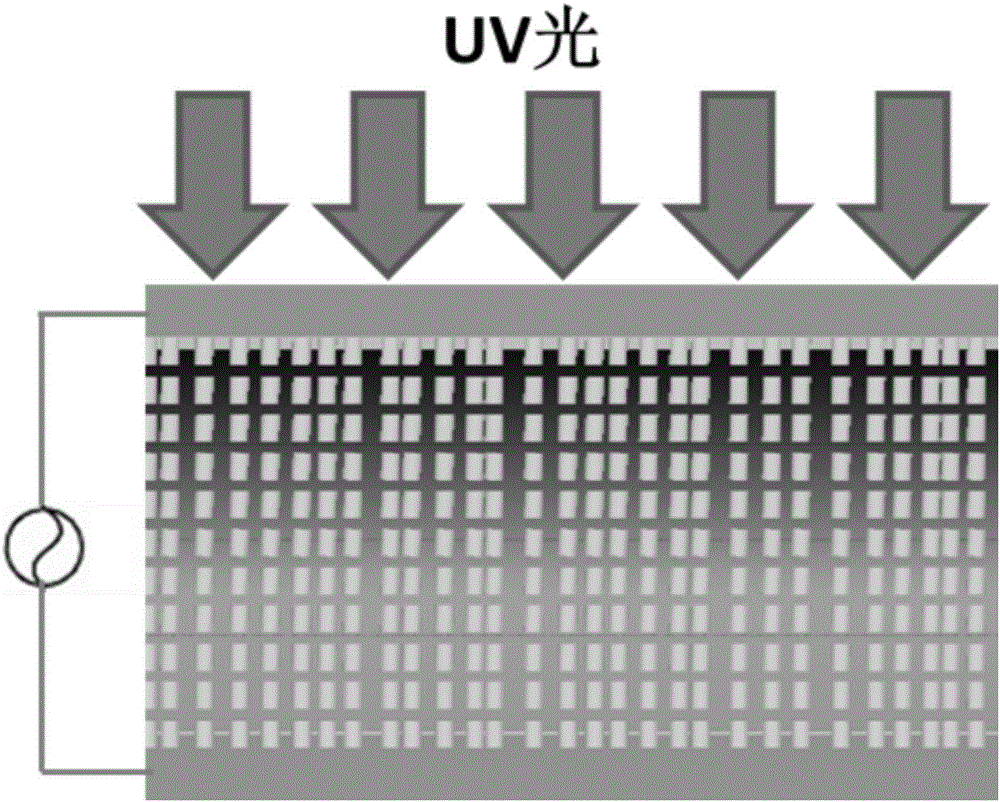

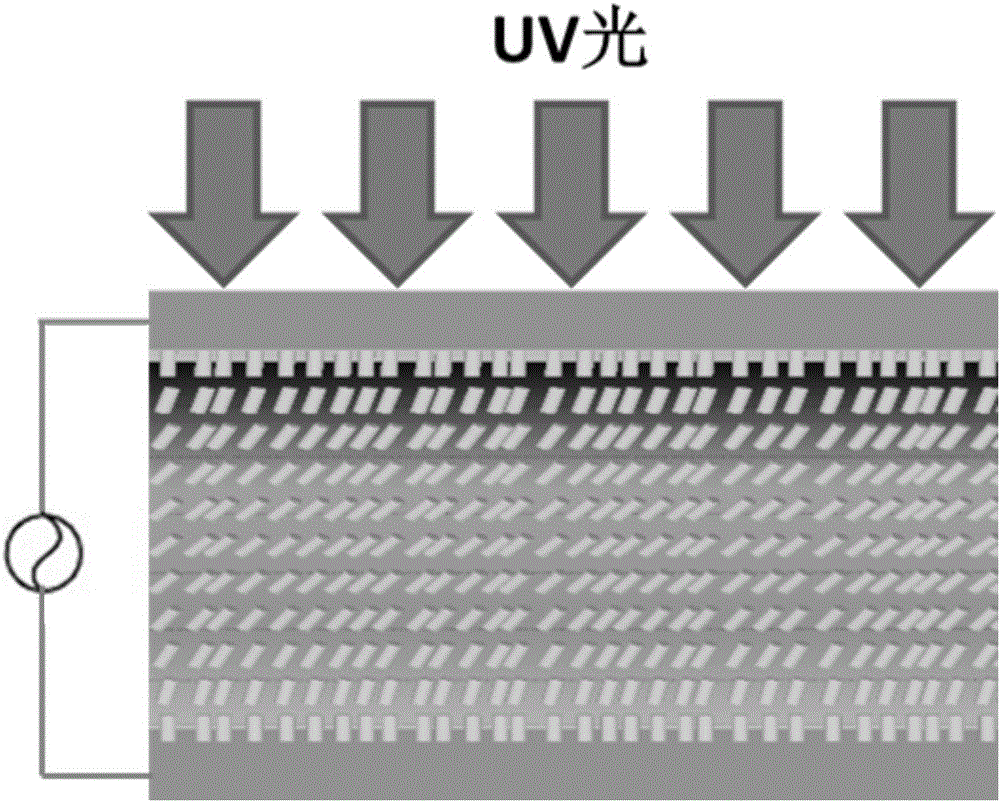

[0055] Specific implementation mode one: combine Figure 4 , Figure 5 , Image 6 , Figure 7 Describe this embodiment mode, a device for improving the optical alignment of a sleeve panel in this embodiment mode, including a sleeve cut substrate 1, N-row chip one 2, N-row chip two 3, and is characterized in that it also includes a photomask 4;

[0056] The N-row chips one (2) and the N-row chips two (3) are arranged alternately and sequentially to form an alternate arrangement structure, and are installed on the nesting substrate 1;

[0057] The area of the chip two 3 is greater than the area of the chip one 2;

[0058] The photomask 4 is used to cover N row chip one (2) and N row chip two 3, so that ultraviolet light passes through the photomask to irradiate N row chip one 2 and N row chip two 3;

[0059] Said N is a positive integer.

specific Embodiment approach 2

[0060] Embodiment 2: This embodiment is different from Embodiment 1 in that: the number of pixels per inch (PPI) in the operable area (AA) of the N columns of chips (Chip) with different areas is different.

[0061] The difference in the number of pixels per inch (PPI) affects the size of the liquid crystal pre-tilt angle.

[0062] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0063] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is:

[0064] The pixels include:

[0065] a first alignment film formed on the first substrate and a second alignment film formed on the second substrate and facing the first alignment film;

[0066] A plurality of adjacent domains, each of which includes a normal luminance area and a domain boundary area, each domain boundary area defining a partial area between adjacent domains.

[0067] Figure 9 is a perspective view of a partial cross-section of a liquid crystal display panel showing the combination of a liquid crystal layer and a substrate with a polarizer and an alignment film. refer to Figure 9 The liquid crystal display panel 5 has a first substrate 6 , a second substrate 10 and a liquid crystal layer 14 interposed between the first substrate 6 and the second substrate 10 .

[0068] like Figure 9 As shown, the first polarizer 8 is fabricated in the form o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com