Axial modification method of involute straight toothed spur gear pair and special parametric CAD (computer aided design) system matched with axial modification method

A technology of spur gears and involutes, applied in geometric CAD, electrical digital data processing, design optimization/simulation, etc., can solve the problem of meshing performance analysis and Problems such as performance evaluation, inability to accurately calculate the strength of the modified gear, and difficulty in optimizing the structure of the modified gear, etc., to achieve high-tech economy, practicality, strong versatility, and the effect of ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

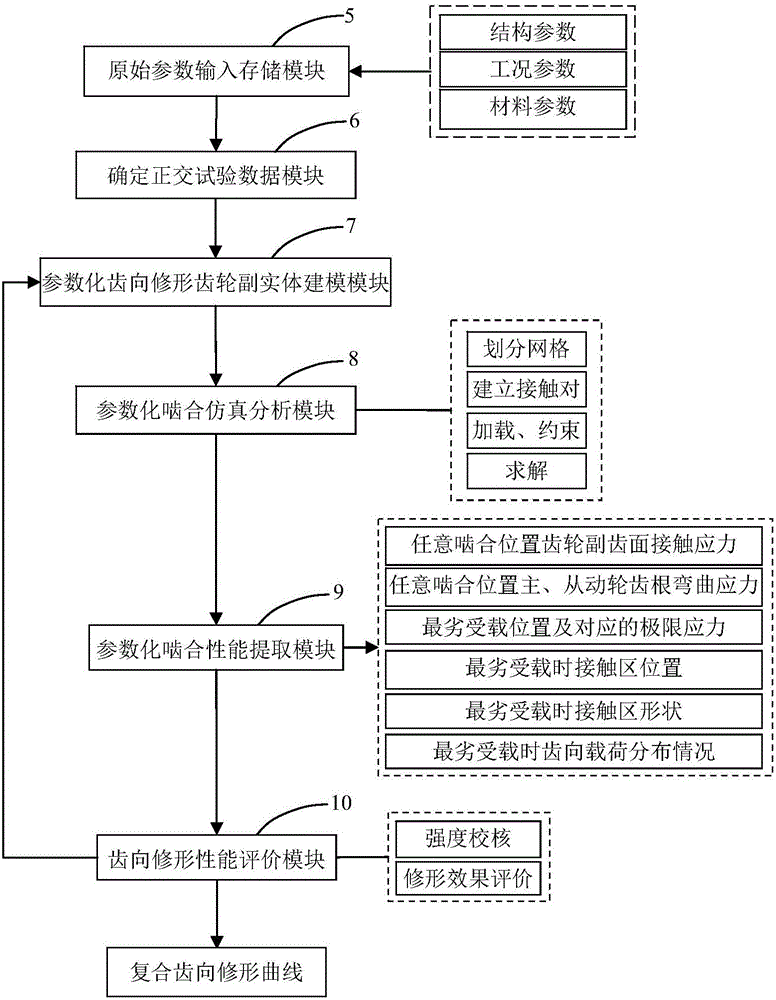

[0102] In the following, the present invention will be described in detail by taking a pair of involute spur gear pairs that need to be used under two working conditions as an embodiment.

[0103] Description: In the following examples, the original parameters of a pair of involute spur gear pairs that need to be used in two working conditions are shown in Table 1.

[0104] Table 1 Original parameters of involute spur gear pair

[0105]

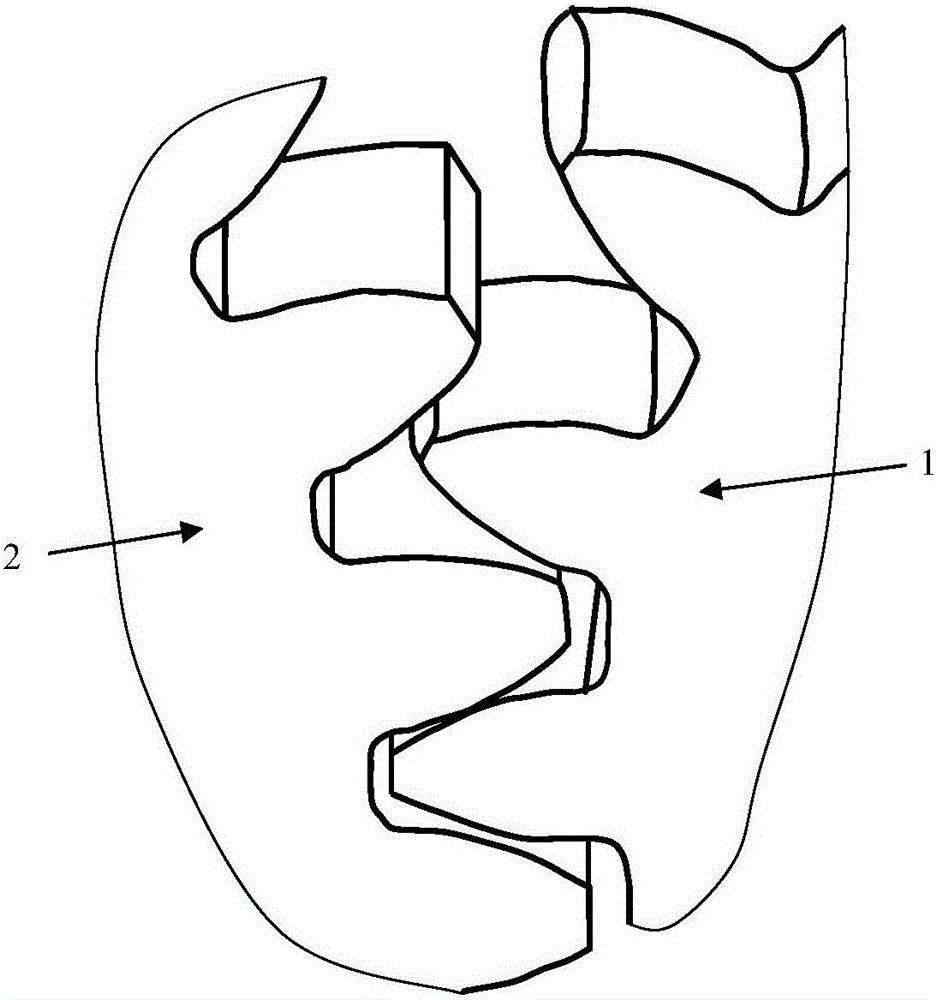

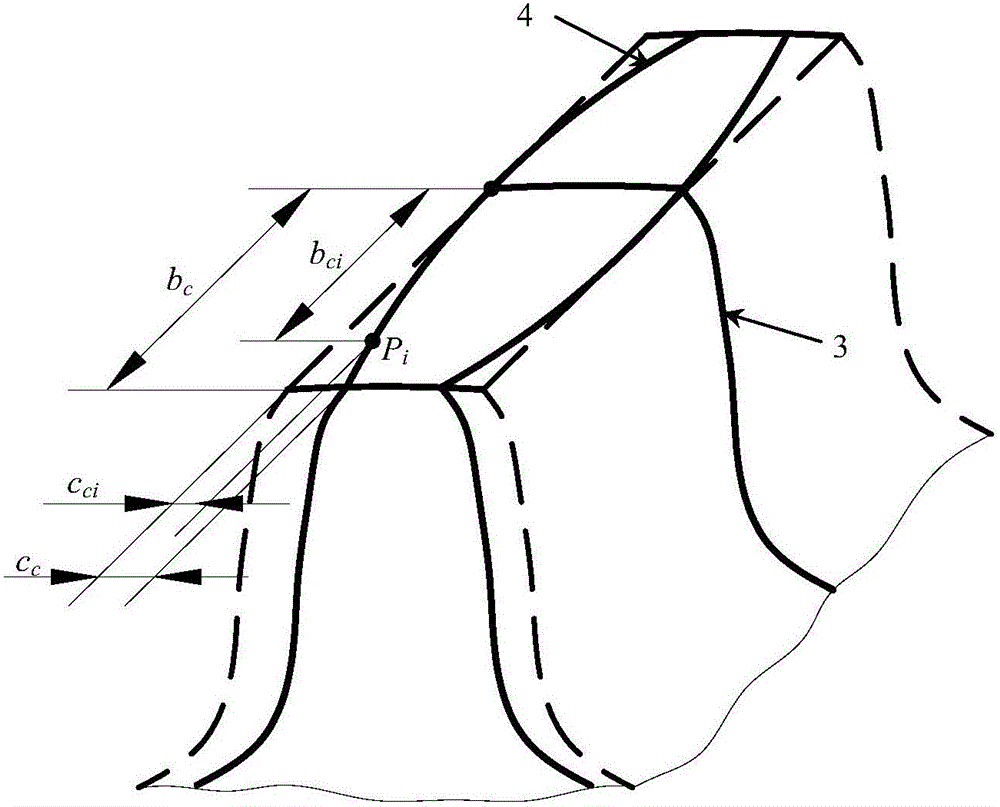

[0106] like figure 1 As shown in the figure, a method for modifying the tooth direction of an involute spur gear pair, only one gear in the gear pair is modified, the gear is named as gear A; the other gear in the gear pair is named as Gear B; it is characterized in that the compound tooth direction modification curve of the above-mentioned gear A satisfies the following general formula (1):

[0107] c c i = αc c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com