Optimal design method for block rotor switched reluctance motor

A rotor switch and reluctance motor technology, applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve problems such as low calculation efficiency, cumbersome process, and inability to obtain the mathematical relationship of the optimization target, so as to achieve easy engineering implementation, Easy to achieve, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

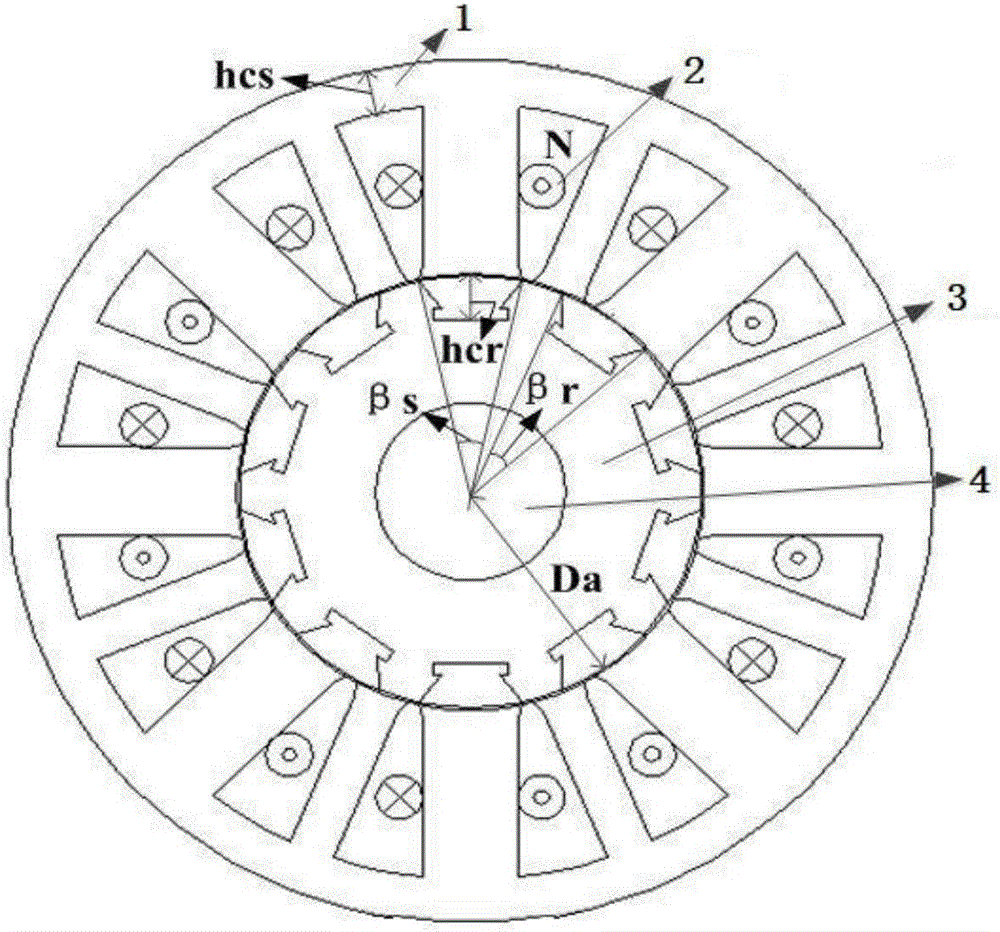

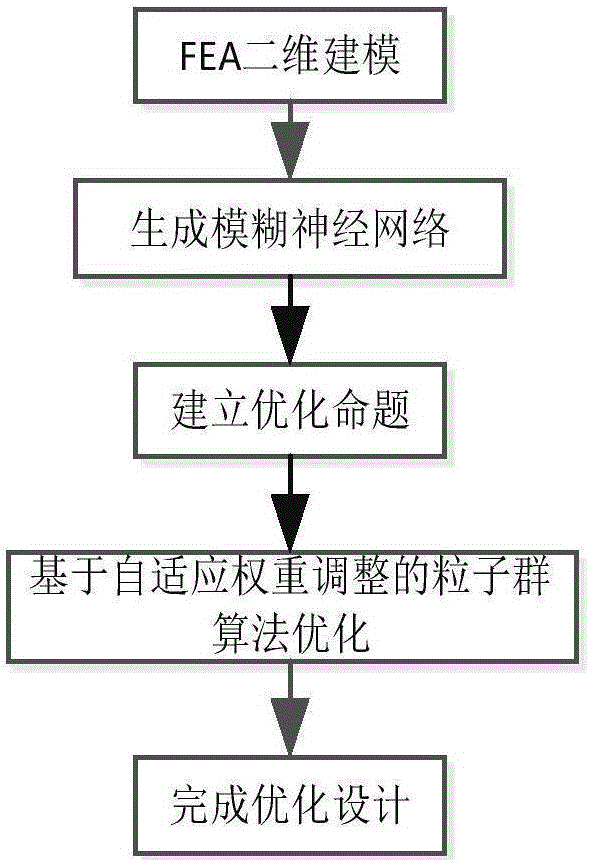

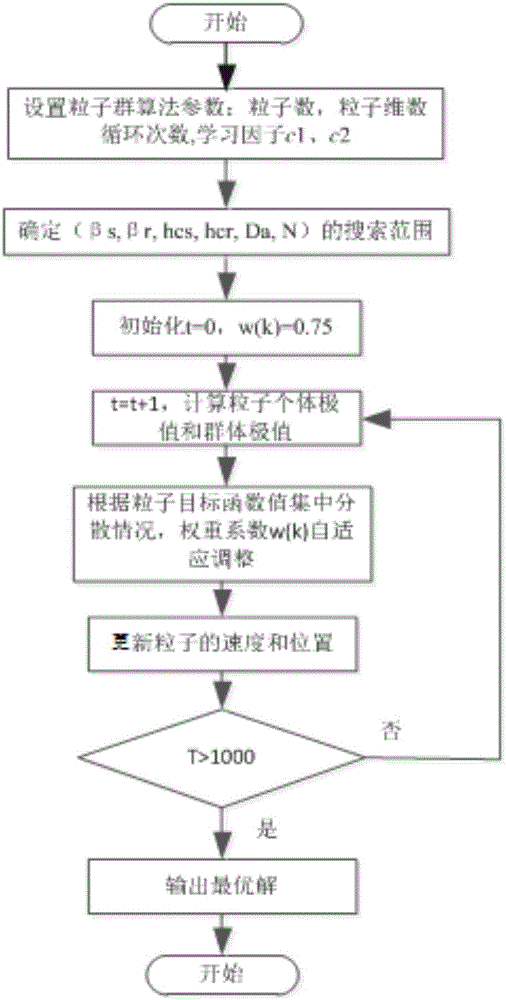

[0020] see figure 2 , using two-dimensional finite element software to establish a finite element model for the segmented rotor switched reluctance motor to obtain the torque ripple and motor efficiency under different structural parameters, and thus construct a sample data space set {K T , η, β s , β r 、h cs 、h cr 、D a , N}, where K T is the torque ripple coefficient, η is the motor efficiency, β s and beta r Respectively represent the stator pole arc and rotor pole arc of the motor, h cs and h cr Respectively represent the stator yoke thickness and rotor block radial height of the motor, D a Indicates the outer diameter of the rotor, and N is the number of turns of the winding.

[0021] The sample data space set {K T , η, β s , β r 、h cs 、h cr 、D a , N} as the input of the fuzzy neural network, input the fuzzy neural network, after the training of the fuzzy neural network, the output is a non-parametric model of the block rotor switched reluctance motor, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com