Oil refining enterprise equipment reliability performance management assessment method

A reliability and equipment technology, applied in the evaluation field of equipment reliability performance management of oil refining enterprises, can solve problems such as failure to comprehensively consider the measurement of operating system or equipment reliability, poor quality of inspection and maintenance, and control of equipment operating conditions, etc. The effect of equipment unplanned parking incidents, improving performance management, and reducing enterprise operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

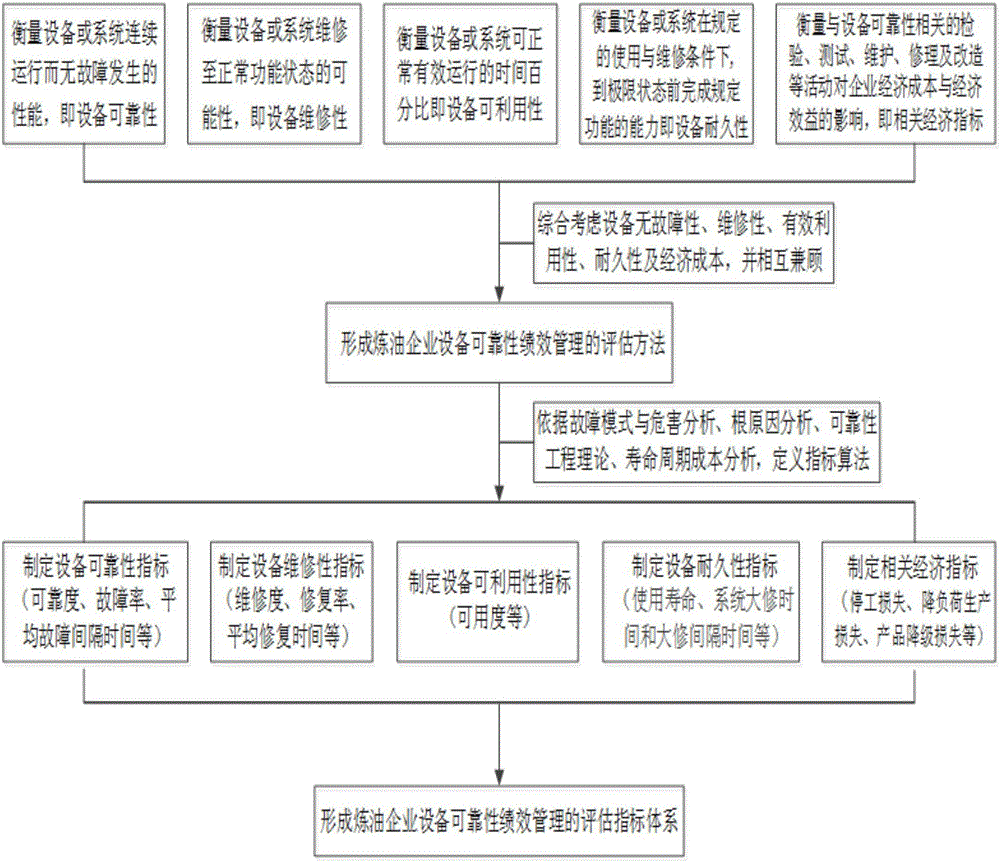

[0020] In order to overcome the equipment performance management of oil refining enterprises, the reliability of operating equipment or systems is not considered comprehensively, and there is a lack of quantitative reliability performance management index system, resulting in low equipment reliability, poor maintainability and low utilization rate, which not only increases the economy Loss, waste of production costs, and seriously affect the long-term safe operation of oil refining and chemical enterprises. The invention provides an evaluation method for equipment reliability performance management of oil refining enterprises, which includes comprehensively considering and measuring the trouble-free performance, maintainability, effective utilization, durability and economical efficiency of equipment or systems, and thus determining a set of equipment reliability performance management methods for oil refining enterprises. The index system of equipment reliability performance m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com