Cooling apparatus and cooling method for polyethylene insulating sheath of crosslinked cable after extrusion

A polyethylene insulated and cross-linked cable technology, applied in the direction of conductor/cable insulation, cable/conductor manufacturing, circuit, etc., can solve problems such as affecting the surface quality of the cable, and achieve the effect of increasing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

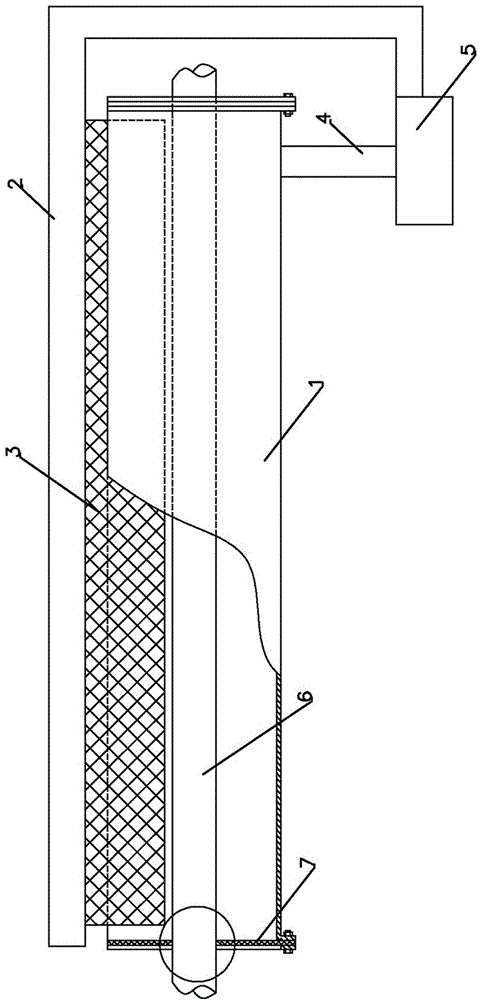

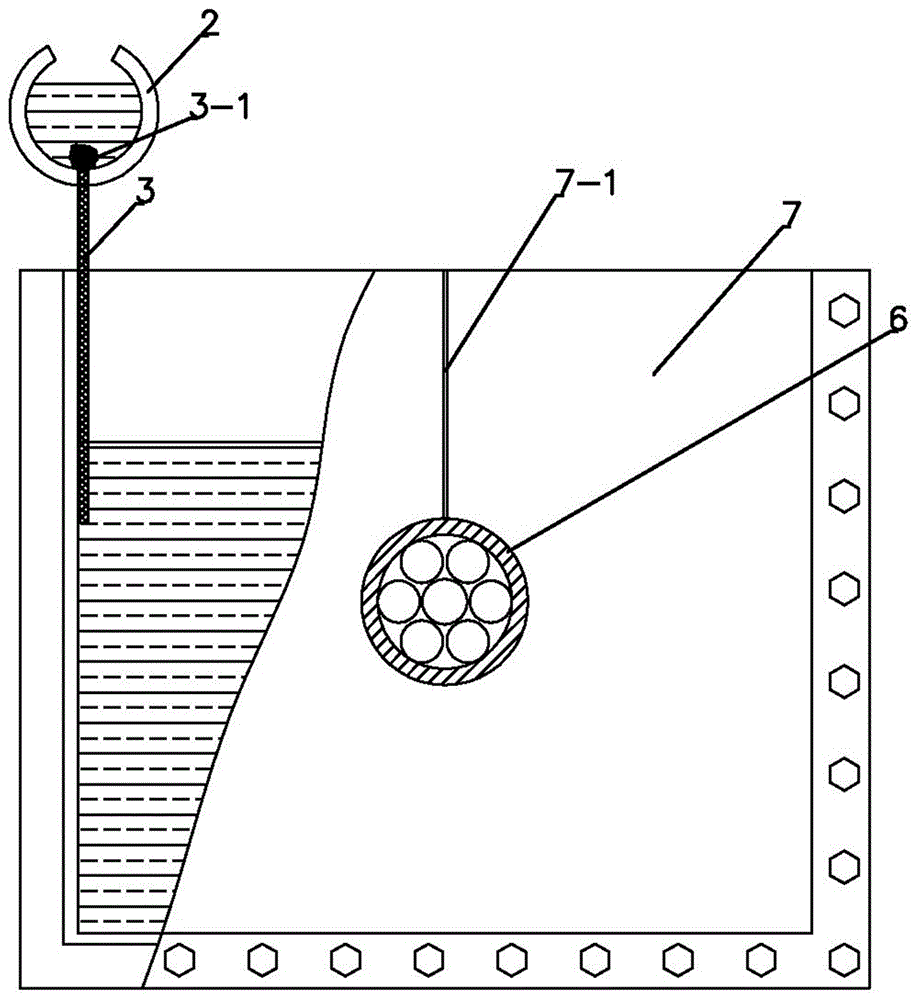

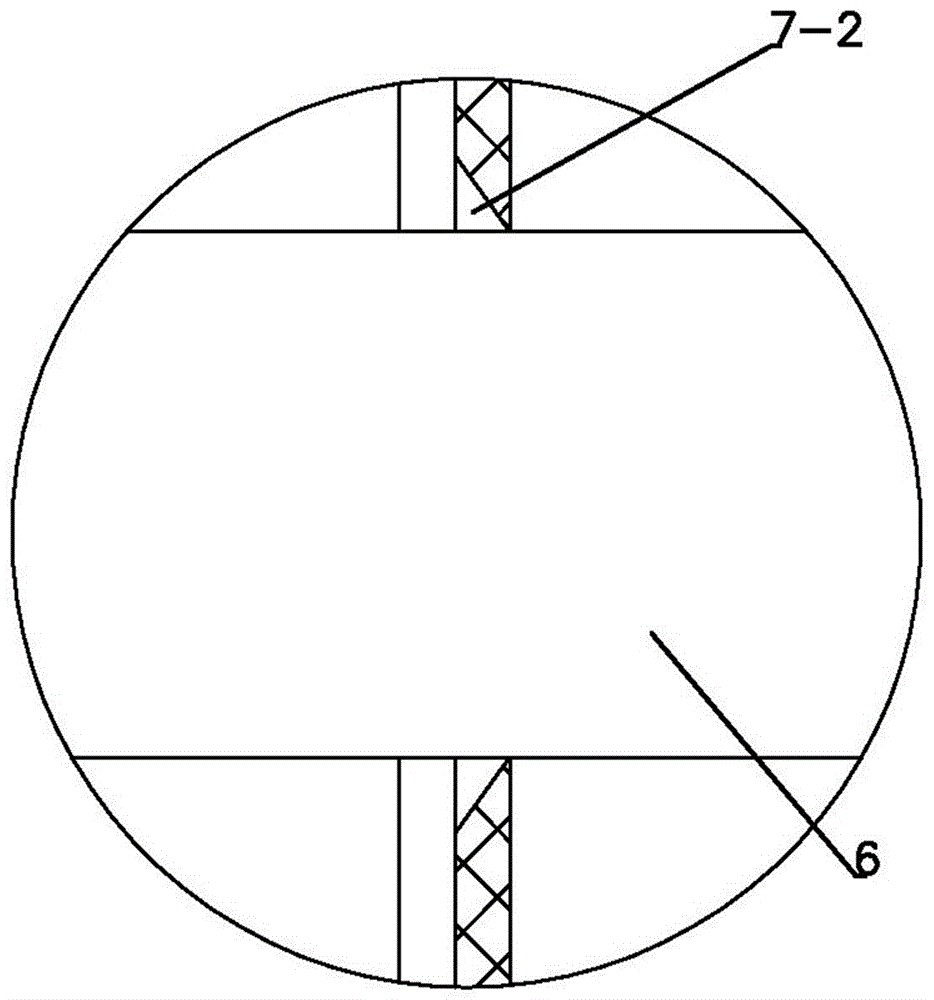

[0024] Embodiment one: see Figure 1-7 , in the figure, a cross-linked cable polyethylene insulated sheath cooling device after extrusion, including a groove-shaped pool body, a water inlet structure is provided on the upper part of the pool, a water outlet structure is provided on the lower part of the pool, and a water outlet structure is provided between the water outlet structure and the water inlet structure. Water circulation power device, the two ends of the trough-shaped pool body are provided with plate-shaped soft silicone plugs, and the periphery of the soft silicone plugs is sealed and connected with the two ends of the pool body through "concave"-shaped pressure plates and bolts. The middle part of the soft silicone plugs There is a cable hole, and there is a vertical gap from the upper edge of the soft silicone plug. The lower part of the gap is connected with the cable hole. This structure can quickly and conveniently install the cable jacket into the cable hole,...

Embodiment 2

[0029] Embodiment 2: A method for cooling after extrusion of the cross-linked cable polyethylene insulating sheath carried out according to the device of Embodiment 1, comprising the following steps,

[0030] a. Add soap liquid to the circulating water, driven by the circulating power device, the circulating water goes up to the upper slow water inlet structure, slowly flows into the trough-shaped pool along its textile, and the circulating water in the pool flows again along the outlet structure into the cycle power plant,

[0031] b. Put the extruded cable with insulating sheath down into the cable hole along the gap of the soft silicone plug,

[0032] c. Then install the strip clips to clamp the connection structure formed by the convex strips and grooves at the gaps, so as to avoid a large amount of cooling water leaking from the gaps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com