Short-circuit prevention thermosensitive chip and fabrication method thereof

An anti-short circuit and heat-sensitive technology, which is applied to thermistors, manufacturing resistor chips, circuits, etc., can solve problems such as hindering production and increasing production costs of heat-sensitive chips, so as to reduce the possibility and increase the production of devices cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

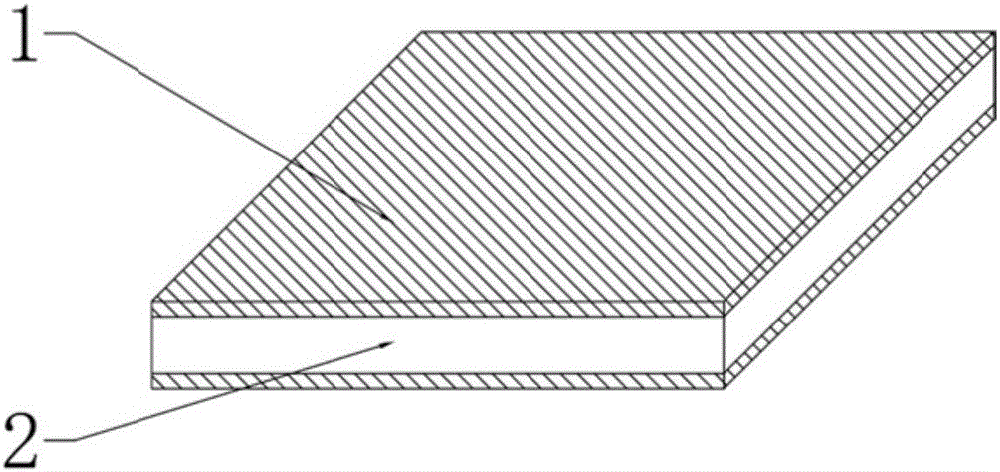

[0029] see Figure 4 and Figure 5 , which are the front view and top view of the structure of the anti-short circuit thermal chip in this embodiment, respectively. The thermosensitive chip comprises a thermosensitive substrate 10, a first metal electrode layer 20 and a second metal electrode layer 30, and the first metal electrode layer 20 and the second metal electrode layer 30 are respectively layered on the thermosensitive substrate 10 on opposite surfaces.

[0030] One surface of the heat-sensitive substrate 10 includes an electrode region (not shown) and an insulating region 12 . The insulating region 12 is disposed around the periphery of the electrode region. The first metal electrode layer 20 is disposed on the surface of the electrode area, and the second metal electrode layer 30 is disposed on the other surface of the thermal chip opposite to the electrode area. Specifically, the size of the first metal electrode layer 20 is smaller than the size of the surface ...

Embodiment 2

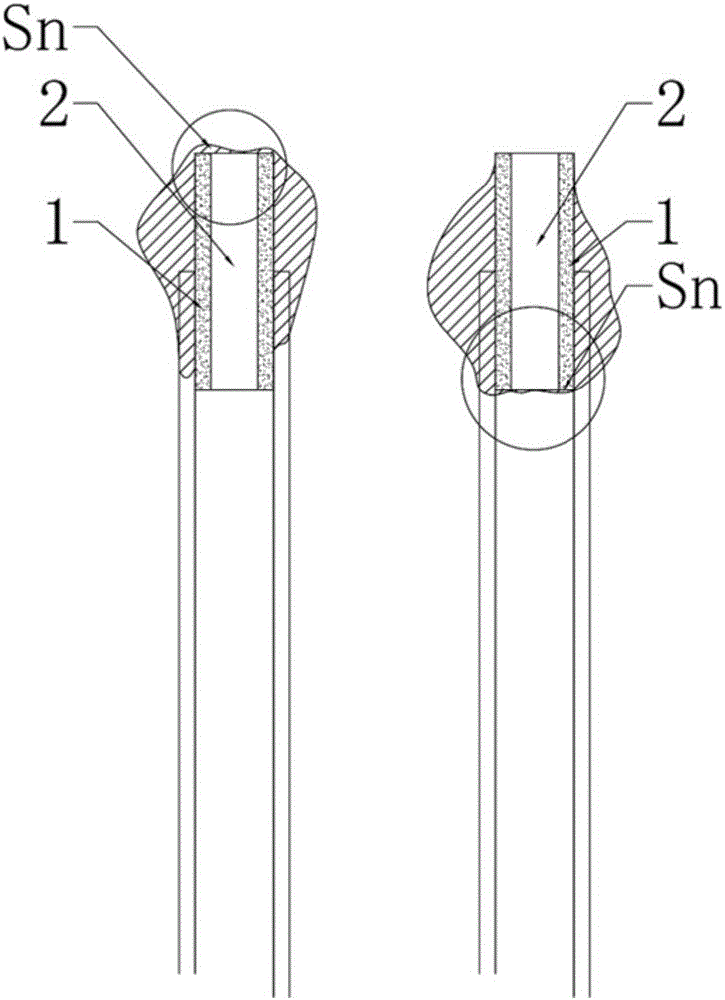

[0043] Please also see Figure 8 and Figure 9 , which are the front view and top view of the structure of the anti-short circuit thermal chip in this embodiment, respectively. The thermosensitive chip comprises a thermosensitive substrate 10, a first metal electrode layer 20 and a second metal electrode layer 30, and the first metal electrode layer 20 and the second metal electrode layer 30 are respectively layered on the thermosensitive substrate 10 on opposite surfaces.

[0044]Both surfaces of the heat-sensitive substrate 10 include electrode regions (not shown) and insulating regions 12 . The insulating region 12 is disposed around the periphery of the electrode region. The first metal electrode layer 20 and the second metal electrode layer 30 are respectively layered on the surfaces of the two electrode regions. Specifically, the size of the first metal electrode layer 20 is smaller than the size of the surface of the thermosensitive substrate, and the first metal el...

Embodiment 3

[0058] Taking a thermosensitive chip with a resistance value R=10KΩ±5% at 25°C as an example, a preparation method thereof is as follows.

[0059] S1: Preparation of heat-sensitive substrate: prepare 10KΩ heat-sensitive substrate powder, sinter the powder at high temperature to form an ingot; then cut the ingot into pieces.

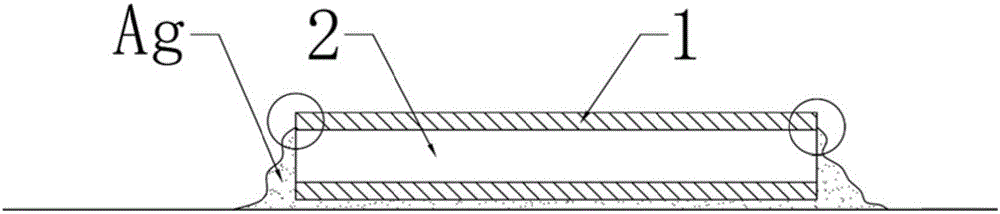

[0060] S2: Print metal paste on both sides of the heat-sensitive substrate and sinter it to form electrodes, and form horizontal and vertical grooves staggered on the electrodes on one side of the heat-sensitive substrate. Specifically, silver electrodes are first printed on one side of the heat-sensitive substrate and dried. Then, grid-shaped silver electrodes are printed on the other side of the heat-sensitive substrate and dried. High-temperature sintering makes the electrode and heat-sensitive substrate combined. Then put it into a constant temperature oil bath at 25°C for resistance testing and cleaning.

[0061] S3: According to the resistivity f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com