Cascade utilization recycle process of energy storage lithium ion battery

A lithium-ion battery and battery technology, applied in the field of lithium-ion battery recycling, can solve the problems of endangering the personal safety of operators, low work efficiency, and low material recycling rate, and achieve the effect of ensuring personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

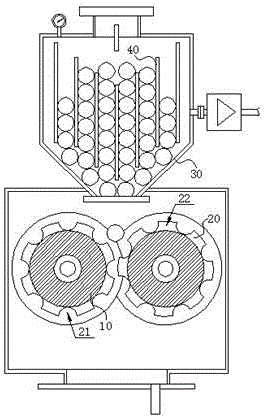

[0020] refer to figure 1 , a step-by-step energy storage lithium-ion battery recycling process provided in this embodiment includes the following steps:

[0021] Step 1. Construct a closed dismantling operation space, and the dismantling operation space includes interconnected battery feeding bins for continuously providing lithium-ion batteries for disassembly operations, and lithium ion batteries for providing lithium-ion batteries to the battery feeding bins. The battery dismantling bin for dismantling the battery; the battery feeding bin includes two symmetrically arranged inclined bottom walls 30 at the bottom, the two inclined bottom walls 30 are parallel to the axes of the two squeezing rollers, and the two inclined bottom walls 30 Several battery posture adjustment baffles are arranged on the top of the battery, and several battery posture adjustment baffles 40 are all vertically arranged, and the distance between adjacent battery posture adjustment baffles 40 is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com