A processing method of ultra-thin multi-layer printed circuit board

A technology of printed circuit boards and processing methods, applied in multilayer circuit manufacturing, printed circuit, printed circuit manufacturing, etc., can solve problems such as low efficiency and yield, rising production costs, complicated operations, etc., to reduce difficulty and risk , the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

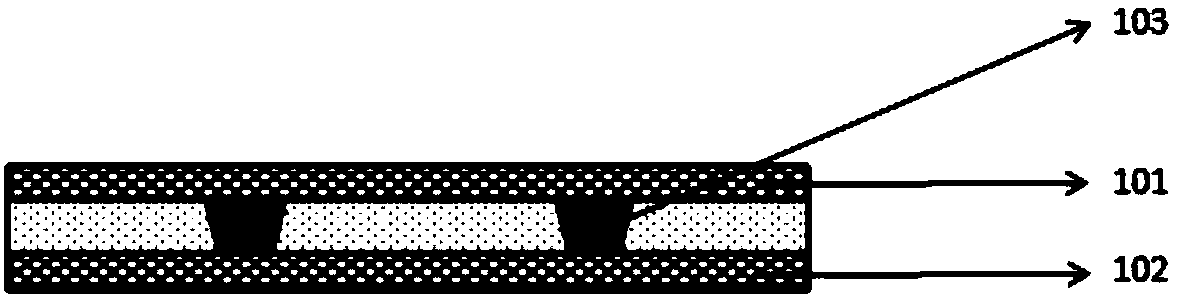

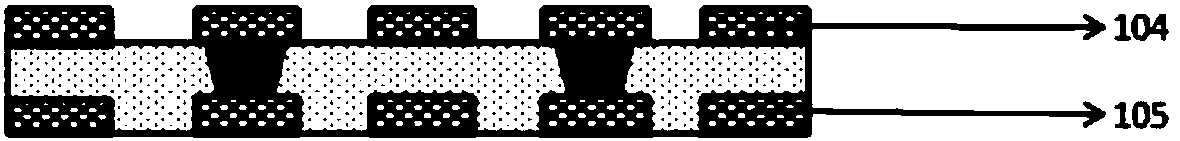

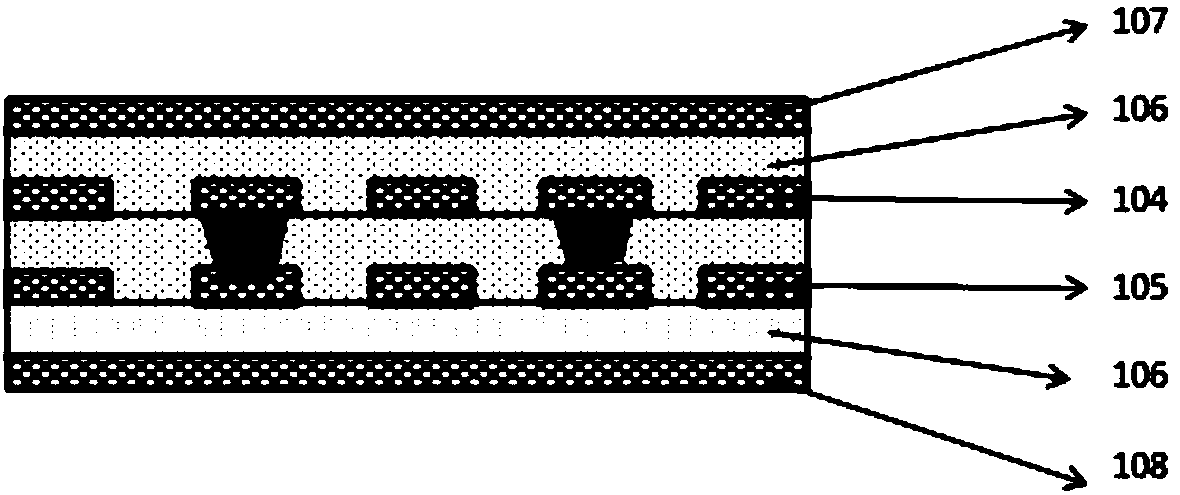

[0056] The main manufacturing process of any interlayer interconnection ultra-thin printed circuit board or semiconductor integrated circuit packaging substrate of the present invention is as follows, taking the ultra-thin six-layer circuit board processing flow as an example:

[0057] The first step is to prepare an ultra-thin carrier copper foil of a specific size. The structure is that an ultra-thin copper foil 202, 202' of 2-5 microns is attached to a carrier copper foil 201, 201' of 12 or 18 microns. In addition, the ultra-thin copper foil 202 and the carrier copper foil 201, the ultra-thin copper foil 202' and the carrier copper foil 201' can be disassembled, and the specific size can be determined according to the actual production situation, which is usually the minimum plate size for the production line process. The ultra-thin carrier copper fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com