Multilayer radiation-protective glove and manufacture process thereof

A technology of radiation protection and manufacturing process, which is applied in the field of radiation protection, γ-ray, neutron comprehensive protection products, and X-ray, and can solve the problem of not adding too much shielding material, high shielding efficiency, tensile strength, bending strength and softness Reduced flexibility and other issues, to achieve the effect of good wearability and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

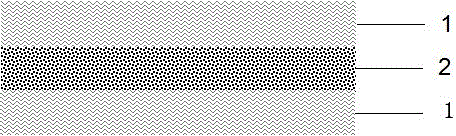

[0054] Such as figure 1 As shown, the multilayer radiation protection glove disclosed by the present invention is divided into three layers, the first layer is a neutron shielding layer, the second layer is a gamma ray shielding layer, and the third layer is a neutron shielding layer.

[0055] The manufacturing steps of multi-layer anti-radiation gloves in the present embodiment are as follows:

[0056] (1) Put 70kg B 4 After C powder, 0.1kg sodium dibutylnaphthalene sulfonate, 0.5kg ammoniacal liquor and 95kg soft water are mixed, carry out ball milling, obtain the first dispersion liquid;

[0057] (2) Put 50kg Bi 2 o 3 After powder, 0.1kg sodium dibutylnaphthalene sulfonate and 70kg soft water are mixed, carry out ball milling, obtain the second dispersion liquid;

[0058] (3) Mix the first dispersion in step (1) with 100 kg of filtered pre-vulcanized natural rubber latex, filter, mature for 2 days, and defoam to obtain the first rubber latex for dipping;

[0059] (4) M...

Embodiment 2

[0068] Such as figure 1 As shown, the multilayer radiation protection glove disclosed by the present invention is divided into three layers, the first layer is a neutron shielding layer, the second layer is a gamma ray shielding layer, and the third layer is a neutron shielding layer.

[0069] The manufacturing steps of multi-layer anti-radiation gloves in the present embodiment are as follows:

[0070] (1) Put 50kg B 4 After C powder, 0.1kg sodium dibutylnaphthalene sulfonate, 0.5kg ammoniacal liquor and 75kg soft water are mixed, carry out ball milling, obtain the first dispersion liquid;

[0071] (2) Add 60kg Gd 2 o 3 After powder, 0.1kg sodium dibutylnaphthalene sulfonate and 80kg soft water are mixed, carry out ball milling, obtain the second dispersion liquid;

[0072] (3) Mix the first dispersion in step (1) with 100 kg of filtered pre-vulcanized nitrile rubber latex, filter, mature for 2 days, and defoam to obtain the first rubber emulsion for dipping;

[0073] (4...

Embodiment 3

[0082] Such as figure 1 As shown, the multilayer radiation protection glove disclosed by the present invention is divided into three layers, the first layer is a neutron shielding layer, the second layer is a gamma ray shielding layer, and the third layer is a neutron shielding layer.

[0083] The manufacturing steps of multi-layer anti-radiation gloves in the present embodiment are as follows:

[0084] (1) Put 60kg B 4 After C powder, 0.1kg sodium dibutylnaphthalene sulfonate, 0.5kg ammonia and 80kg soft water are mixed, carry out ball milling, obtain the first dispersion liquid;

[0085] (2) Add 50kg Gd 2 o 3 After powder, 0.1kg sodium dibutylnaphthalene sulfonate and 70kg soft water are mixed, carry out ball milling, obtain the second dispersion liquid;

[0086](3) Mix the first dispersion in step (1) with 100 kg of filtered pre-vulcanized nitrile rubber latex, filter, mature for 2 days, and defoam to obtain the first rubber emulsion for dipping;

[0087] (4) Mix the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com