High-quality high-yield dustproof moxa stick maker

A high-yield, moxa stick technology, applied in the direction of heating/cooling reflective point instruments, etc., can solve the problems of using a large number of workers, labor-intensive, not compact structure, etc., to ensure the quality of finished products, protect human-machine safety, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

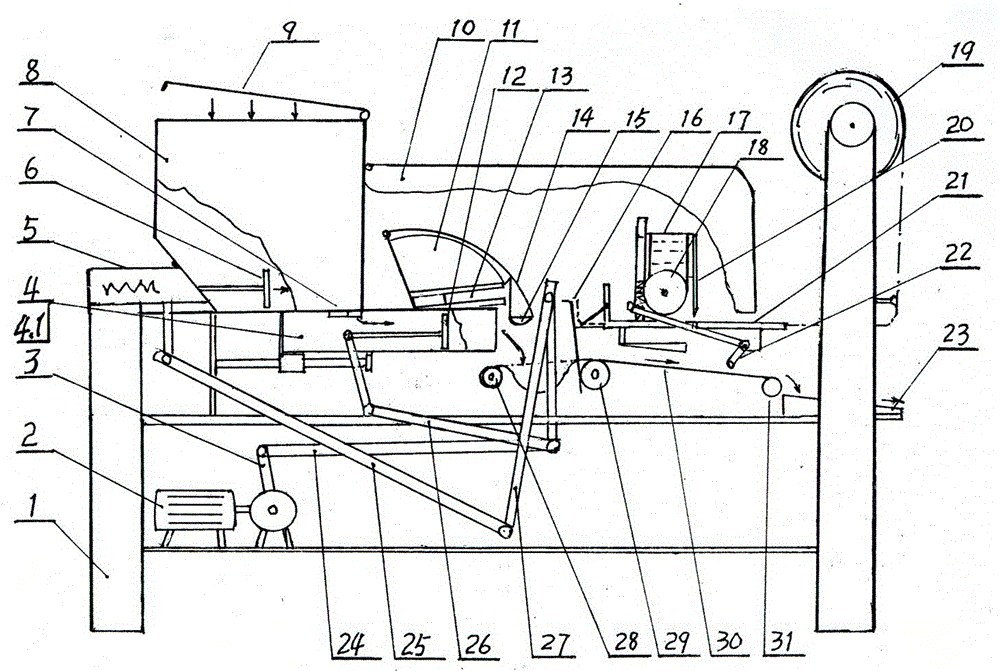

[0035] The present invention creates a kind of embodiment 2 of high-quality and high-yield dust-proof moxa stick machine, see figure 1 , Its structure includes: in the structure of embodiment 1, also described blank forming device, baffle plate, cutting paper cutter, glue box and the upper part of pallet are provided with dustproof cover 10.

Embodiment 3

[0036] The present invention creates a kind of embodiment 3 of high-quality and high-yield dust-proof moxa stick machine, see figure 1 , its structure includes: in the structure of embodiment 1, a protective enclosure (not shown in the figure) is also provided outside the frame 1;

[0037] Also set moxa feeding device (not shown in the figure) upstream of the moxa hopper;

[0038] A moxa stick transport and sorting device (not shown) is also arranged downstream of the moxa stick slide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com