Ultrasonic extraction tank with stirring device

A stirring device, ultrasonic technology, applied in mixers with rotating stirring devices, mixer accessories, solvent extraction, etc., can solve the problems of lengthy extraction process, slow material exchange, poor heat penetration effect, etc., to improve heat penetration The effect of increasing the material, increasing the speed of the material, and shortening the dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

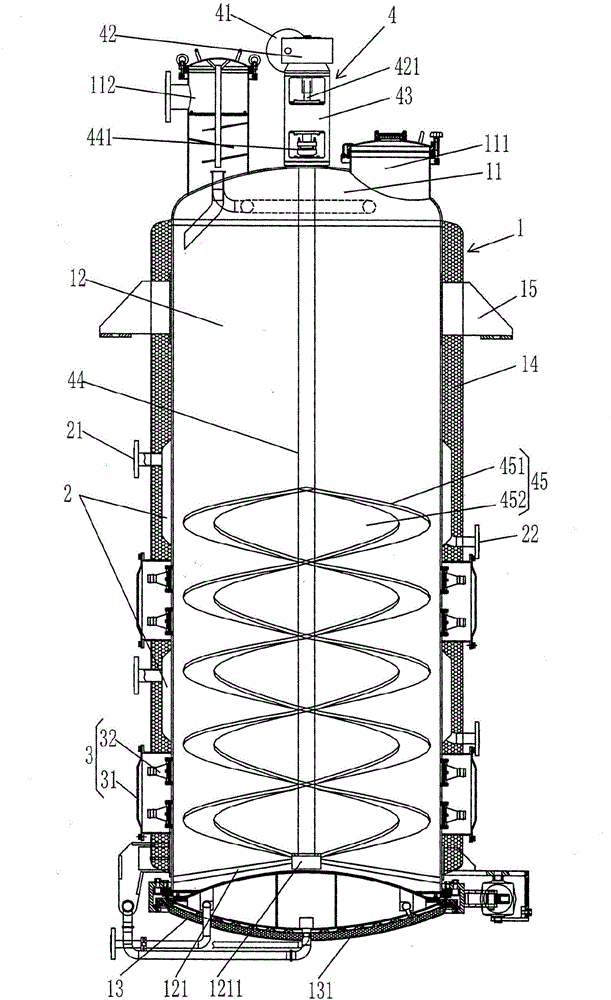

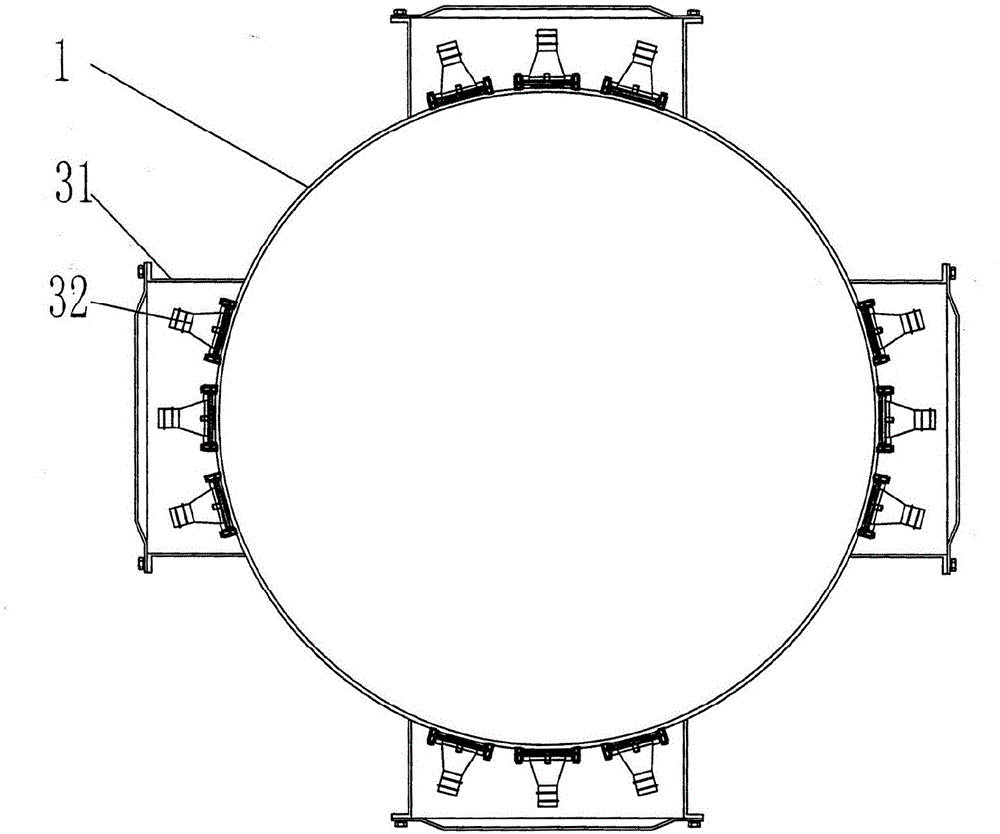

[0017] See figure 1 and figure 2 , shows the tank body 1, the tank body 1 is preferably made of 304 stainless steel, and a tank cover 11 is arranged on the top of the tank body 1, and a sealing gasket is arranged between the tank cover 11 and the tank body 1. The tank cover 11 is provided with a feed port 111 and a secondary steam outlet 112 communicating with the tank cavity 12 of the tank body 1, and a slag discharge door 13 is provided at the bottom of the tank body 1; a heating jacket 2 is shown, the The heating jacket 2 is arranged in the middle of the aforementioned tank body 1 . In this embodiment, the effective volume of the aforementioned tank body 1 is 3000L, specifically: the inner diameter, that is, the diameter of the tank chamber 12, is 1200 mm, and the height is 3000 mm. Since the height of the tank body 1 is relatively high, there are two groups of the aforementioned heating jackets 2 . The ultrasonic generating mechanism 3 is shown, and the ultrasonic gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com