A deep treatment system for sintering/pellet wet desulfurization flue gas

A wet desulfurization and flue gas technology, applied in the field of environmental engineering, can solve problems such as high operating cost, pulverization, and easy occurrence of corrosion, and achieve the effects of avoiding dead ends of flue gas, reducing energy consumption, and uniform flue gas flow field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] The present invention aims at the problems of sintering in the iron and steel industry, wet desulfurization of pellet flue gas and tailing problems, as well as the scaling of traditional wet electrostatic precipitators, which are prone to corrosion, pulverization, and high operating costs. / Pellet wet desulfurization flue gas advanced treatment system.

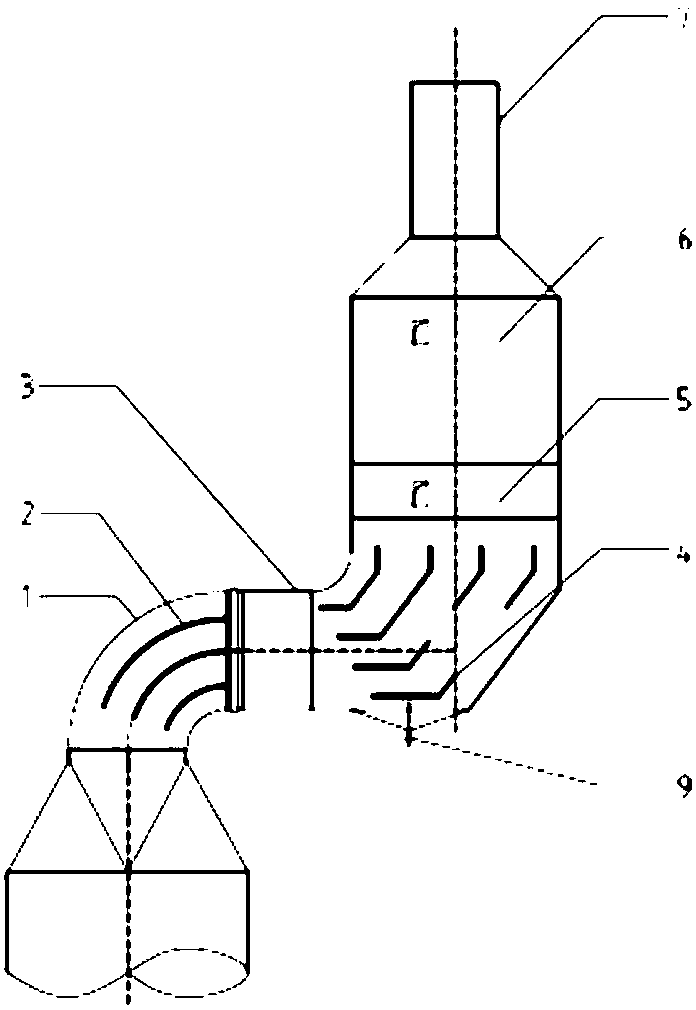

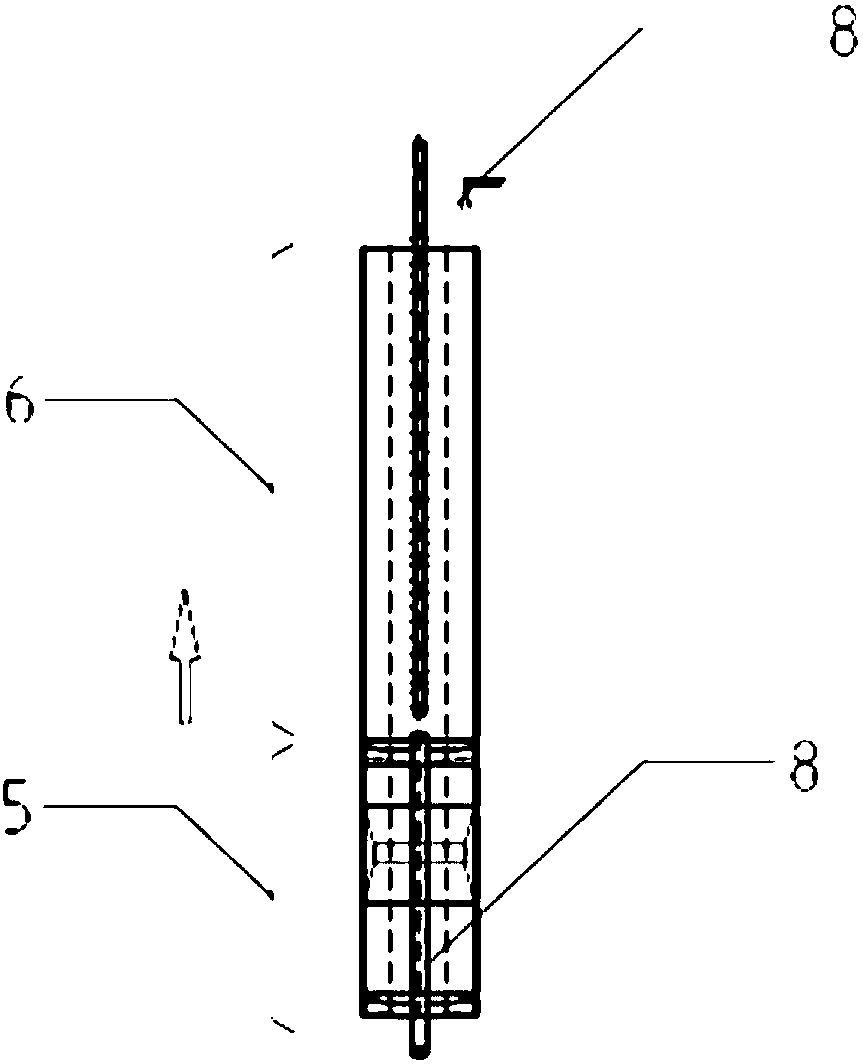

[0032] Such as figure 1 As shown, the deflector 2 is located in the middle flue 1, the middle flue 1 is connected to the system inlet 3, the air flow uniform distribution plate 4 is arranged in the system inlet 3, the tube bundle dust and mist removal device 5 is connected to the system inlet 3, and the honeycomb The wet dust and mist removal device 6 is connected to the tube bundle dust and mist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com