Device and method for separating and recycling magnetic nanometer particles

A magnetic nanoparticle, separation and recovery technology, applied in the field of water purification, can solve the problems of low concentration of magnetic nanoparticle solution, inconvenient maintenance and operation, cumbersome process control, etc., achieve high production efficiency, convenient operation, and improve recovery quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

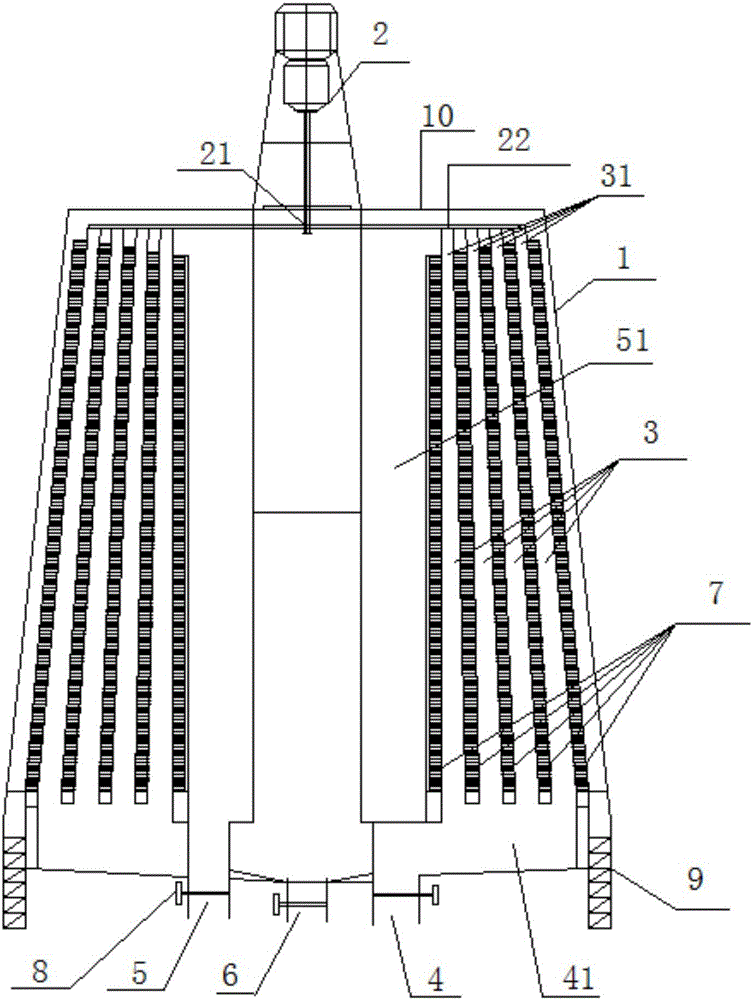

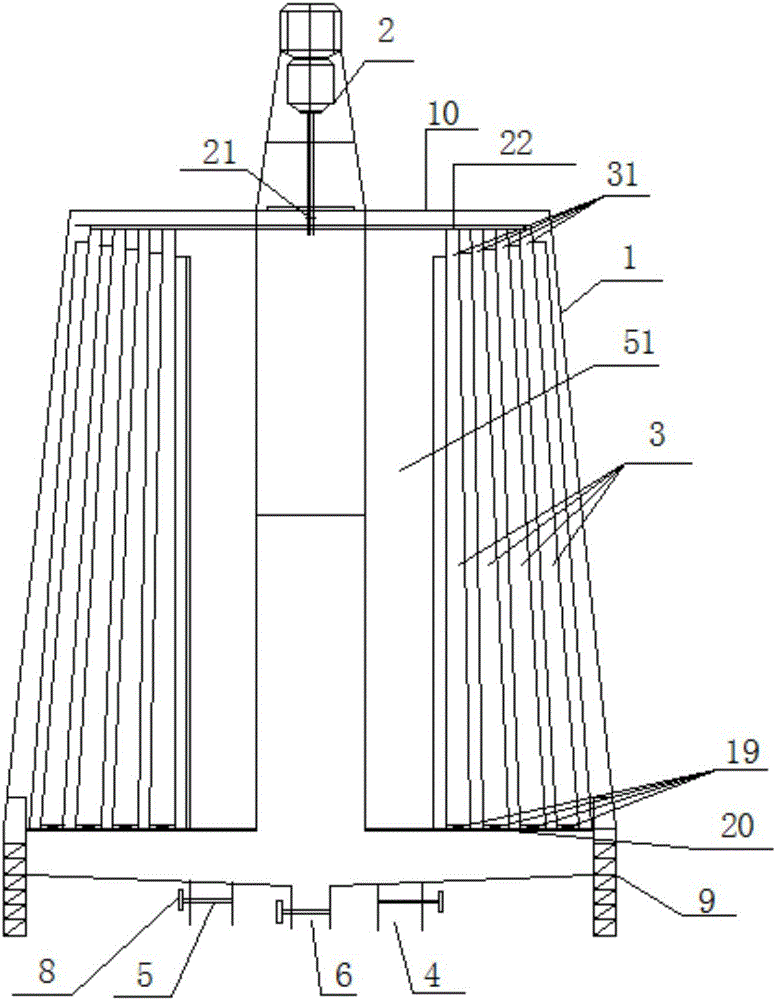

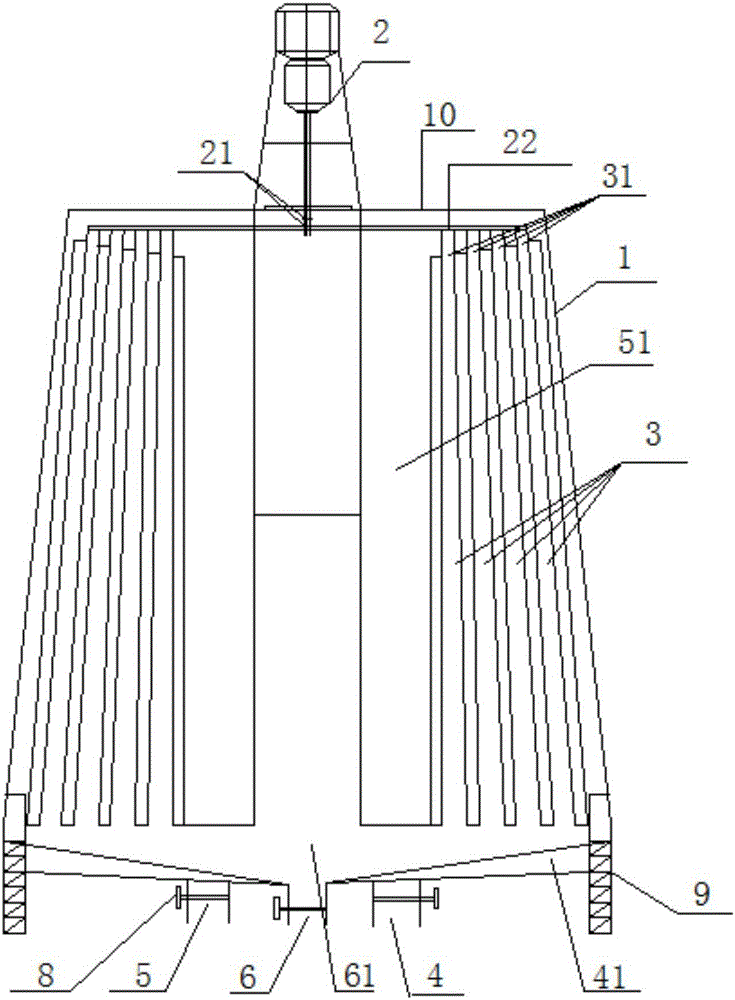

[0032] As mentioned in the background section, the current devices and methods for separating and recovering magnetic nanoparticles are not only inconvenient to operate, but also have low production efficiency.

[0033] Based on the above research, the embodiment of the present invention provides a device and method for separating and recovering magnetic nanoparticles, which can not only continuously perform separation work, but also recover without stopping the machine while separating, which not only improves the Work efficiency, and easy to operate. At the same time, in the recycling process, there is no need for backwashing, which improves the recycling quality.

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] In the following description, specific details ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com