Gas protection device for back face of welding line

A gas protection device, the technology on the back, applied in the direction of providing/removing the protection gas device, welding accessories, etc., can solve the problems of poor sealing effect and gas protection effect, achieve good gas protection effect, convenient and quick assembly and disassembly, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

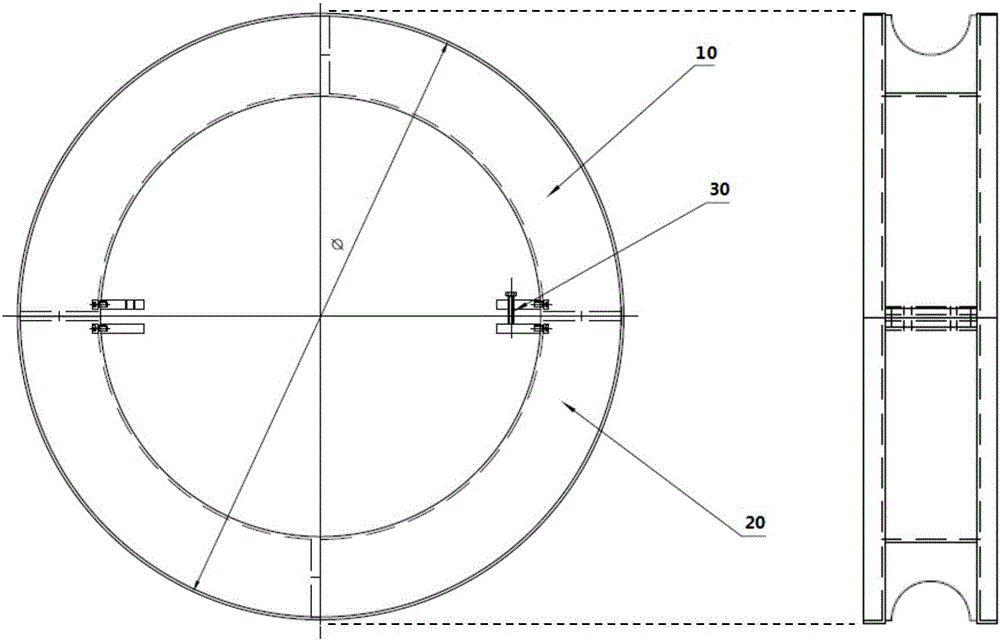

[0037] Such as figure 1 As shown, the gas shielding device for the back of the weld according to the present invention includes a symmetrical first half-ring assembly 10 and a second half-ring assembly 20, and four first bolts 30 connecting the two.

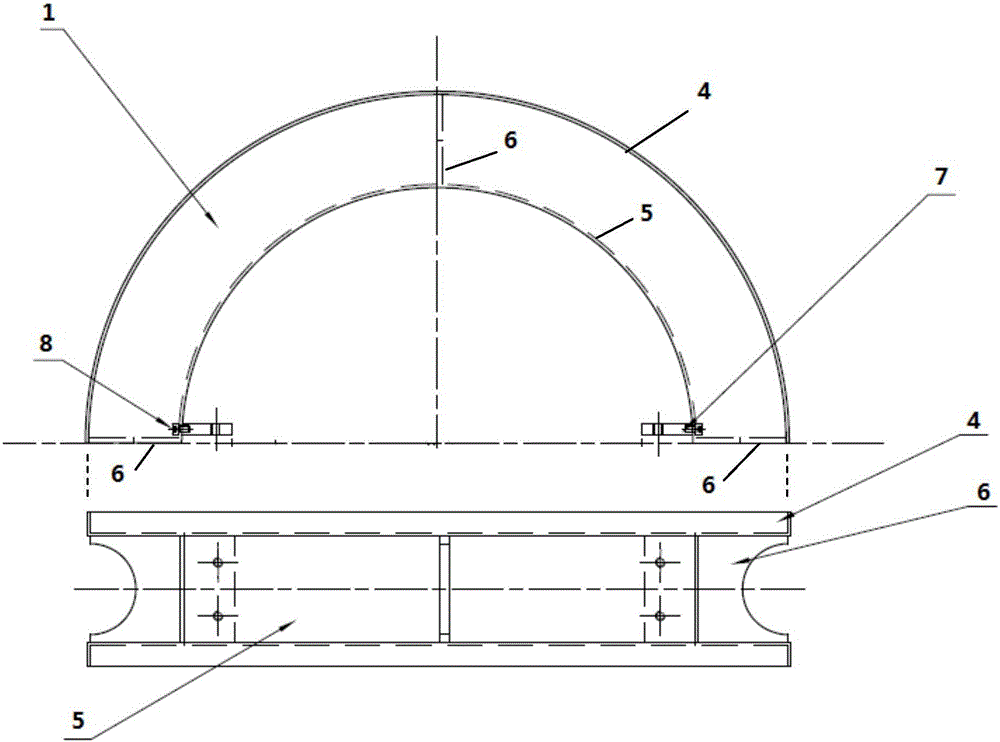

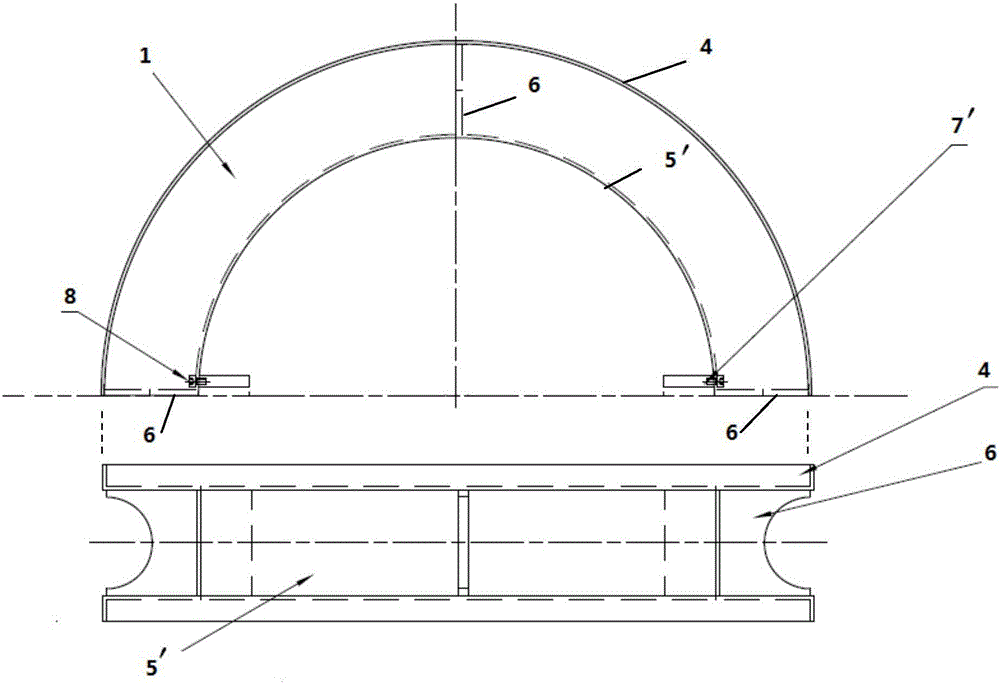

[0038] Such as figure 2 In the shown first half-ring assembly 10, two half-ring plates 1 ( Figure 4 ), two first ring plates 4 ( Figure 5 ), a second ring plate 5 ( Figure 6 ), three ribs 6 ( Figure 8 ), two first fixed blocks 7 ( Figure 9 ), four second bolts 8.

[0039] Wherein, each rib 6 is similar to a concave shape, with figure 2 middle bottom view and Figure 8 In terms of direction, the rib plate 6 includes opposite top and bottom edges, and the same side of the top and bottom edges is vertically provided with a straight inner edge, and the outer edge opposite to the inner edge is inward. The curved arc shape forms a notch on the outside of the rib 6 .

[0040] The three ribs 6 are evenly distributed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com