Machine tool

A machine and workpiece technology, applied in the field of processing machines, can solve problems such as difficult rotation connections, complex maintenance of energy lines, etc., and achieve the effect of all-round processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

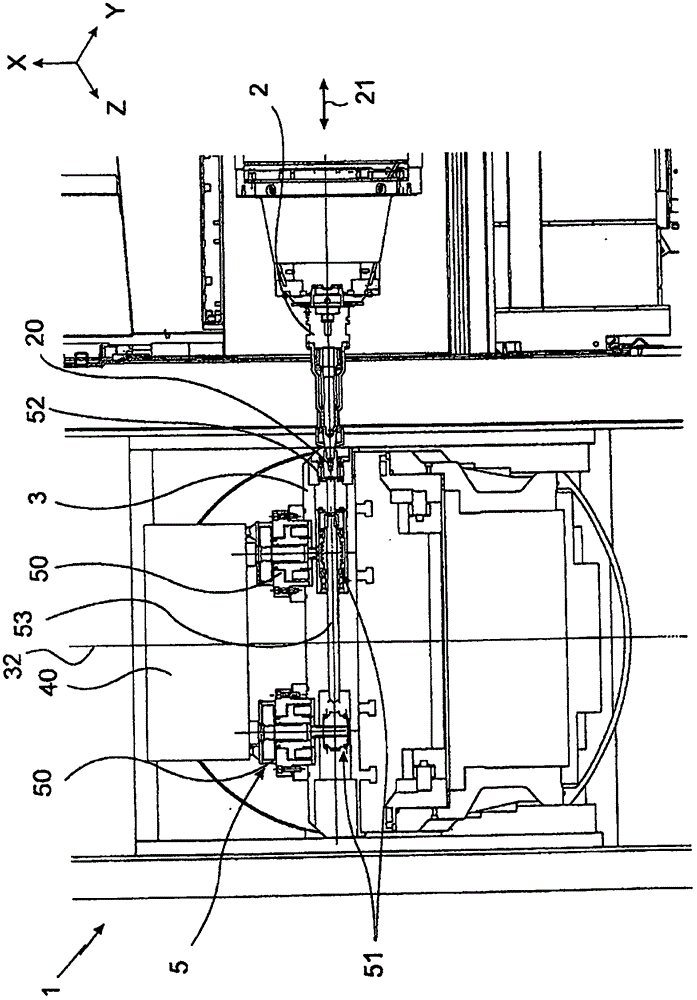

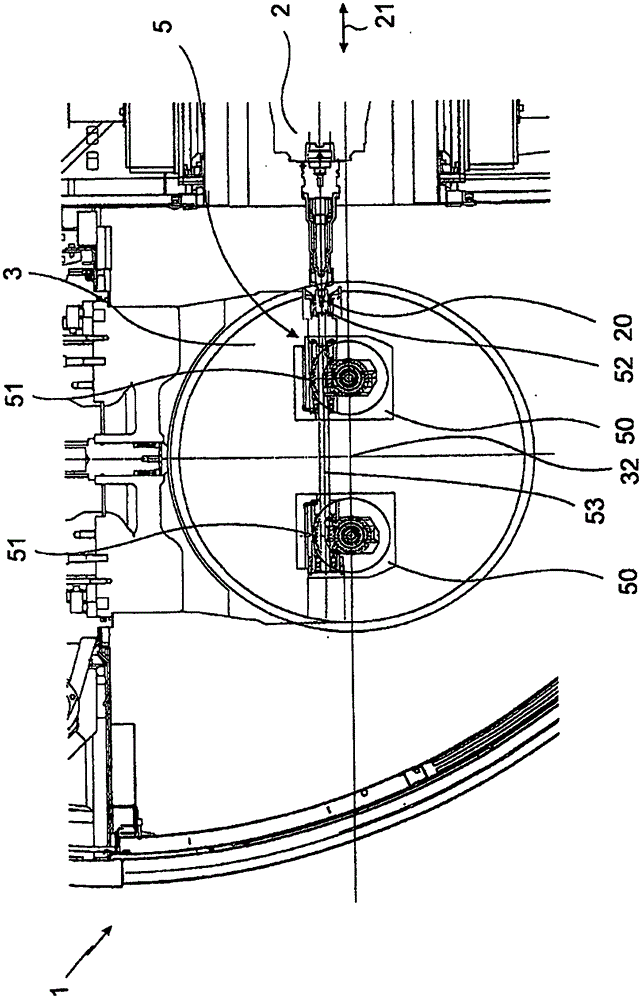

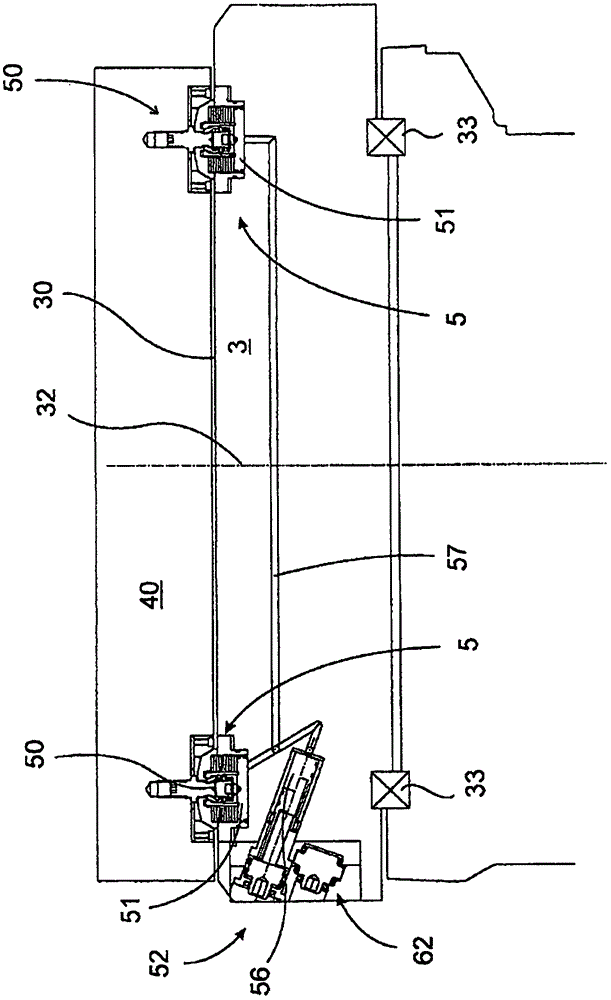

[0053] figure 1 A side view of a processing machine 1 according to a first embodiment is shown. The processing machine 1 is designed to process workpieces, not shown, which are held by a pallet 40. Below the pallet 40 there will be The manner further illustrated is held on a workpiece table 3 . The workpiece table 3 is rotatable about a vertical axis 32 so that the pallet 40 is correspondingly rotatable.

[0054] For machining the workpiece, there is a motor spindle 2 which is designed to receive a tool and drive it rotatably. This can be, for example, a drill or a grinding head. However, the The motor spindle 2 can also accommodate a tool which is designed specifically for actuating the device on the workpiece table 3 in a manner which will be explained further below. For this purpose, for example, a hexagonal head can be accommodated.

[0055] A clamping device 5 is arranged in the workpiece table 3. The clamping device 5 has two clamping mechanisms 50. The clamping mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com