Flame-retardant bi-component polyurethane adhesive and preparation method thereof

A two-component polyurethane and adhesive technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of performance degradation, poor flame retardancy, and improved flame retardancy, and achieve The effect of improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

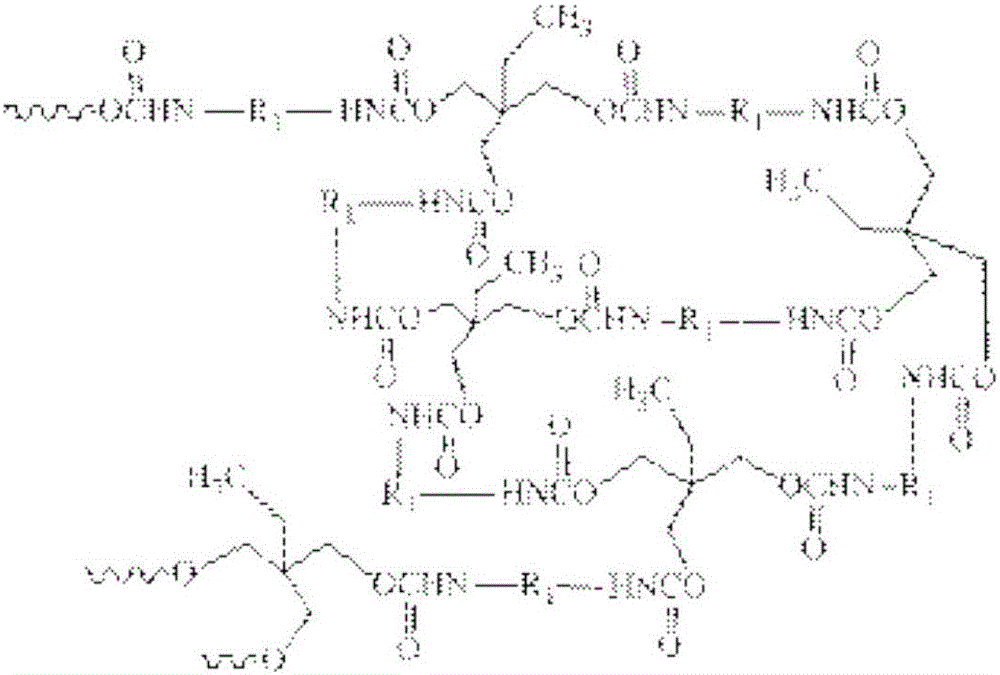

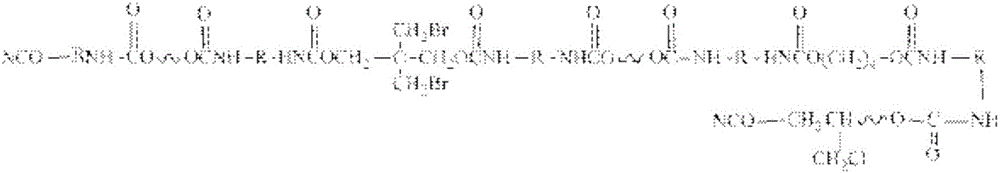

Method used

Image

Examples

Embodiment 1

[0038]A component formula: PPG-1000: 1.00g, TDI: 8.93g. B component formula: BDO: 0.30g, PPG-1000: 6.00g, TMP 1g. The mass percentage content of each component in component A is: the content of diisocyanate TDI is 89.93%, the polyol is polyether polyol PPG-1000, which is 10.07%; no reactive flame retardant is added; each group in component B Points: PPG-1000 is selected for polyol, the content is 82.19%, the content of reactive flame retardant is 0, the cross-linking agent is TMP, the content is 13.70%, and the chain extender is BDO, the content is 4.11%.

[0039] Add the TDI in component A into the three-necked flask, then add the dehydrated PPG-1000 and TMP, stir rapidly, slowly raise the temperature and control it at 80°C, 2 Reaction under protection, sampling analysis—when the NCO mass fraction reaches 10%, the reaction is stopped after about 2.5 hours to obtain a polyisocyanate prepolymer, which is sealed and stored for later use.

[0040] Weigh component B, mix and sti...

Embodiment 2

[0042] A component formula: PPG-1000: 5.30g, PECH-2000: 1.06g, TDI: 5.12g, DBNPG: 1.59g. B component formula: BDO: 0.58g, TMP: 0.59g, PPG-1000: 4.70g, PECH-2000: 0.95g, DBNPG: 1.45g. The mass percentage content of each component in component A is: TDI is used for diisocyanate, and the content is 39.17%; PPG-1000 and PECH-2000 are used for polyols, and the content of PPG-1000 is 40.55%% and the content of PECH-2000 is 8.11%; The reactive flame retardant is DBNPG with a content of 12.17%; the crosslinking agent is 0. Components in component B: PPG-1000 and PECH-2000 are used for polyols, the content of PPG-1000 is 56.83%, and the content of PECH-2000 is 11.49%; the reactive flame retardant is DBNPG, with a content of 17.53%. The agent is TMP, the content is 7.13%, and the chain extender is BDO, the content is 7.01%.

[0043] Add the TDI in component A into the three-necked flask, then add the dehydrated PPG-1000, PECH-2000, DBNPG, stir rapidly, slowly raise the temperature and...

Embodiment 3

[0046] A component formula: PPG-1000: 6.60g, PECH-2000: 2.20g, TDI: 8.61g, DBNPG: 2.0g, B component formula: BDO: 0.80g, TMP: 0.80g, PPG-1000: 6.64g , PECH-2000: 2.21g, DBNPG: 2.40g. The mass percentage content of each component in component A is: TDI is used for diisocyanate, and the content is 44.4%; PPG-1000 and PECH-2000 are used for polyols, and the content of PPG-1000 is 34.0%% and the content of PECH-2000 is 11.3%; The reactive flame retardant is DBNPG with a content of 10.3%; the crosslinking agent is 0. Each component in component B: PPG-1000 and PECH-2000 are selected for polyols, and the content of PPG-1000 is 51.7%; the content of PECH-2000 is 17.2%; the reactive flame retardant is DBNPG with a content of 18.7%, and the crosslinking agent is selected TMP, the content is 6.2%, the chain extender is BDO, the content is 6.2%.

[0047] First add quantitative TDI into the three-necked flask, then add dehydrated PPG-1000, PECH-2000, DBNPG respectively, stir at a consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com