A Hydraulic Adjustable Variable Compression Ratio Engine

A compression ratio and adjustable technology, applied in the field of hydraulically regulated variable compression ratio engines, can solve the problems of inertia force, vibration and noise increase, engine external size increase, friction loss power increase, etc., to avoid side pressure, The effect of easy control process and low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

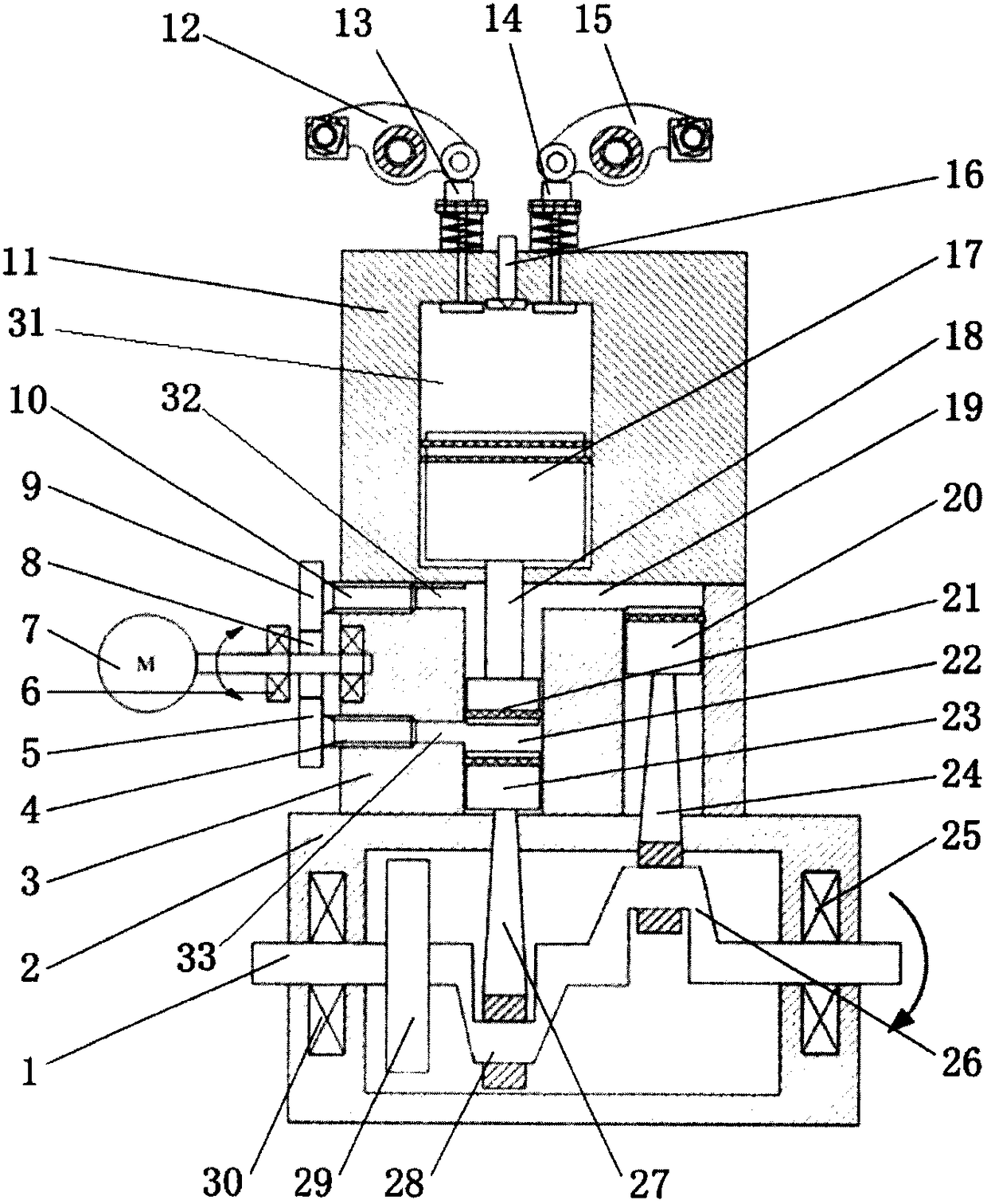

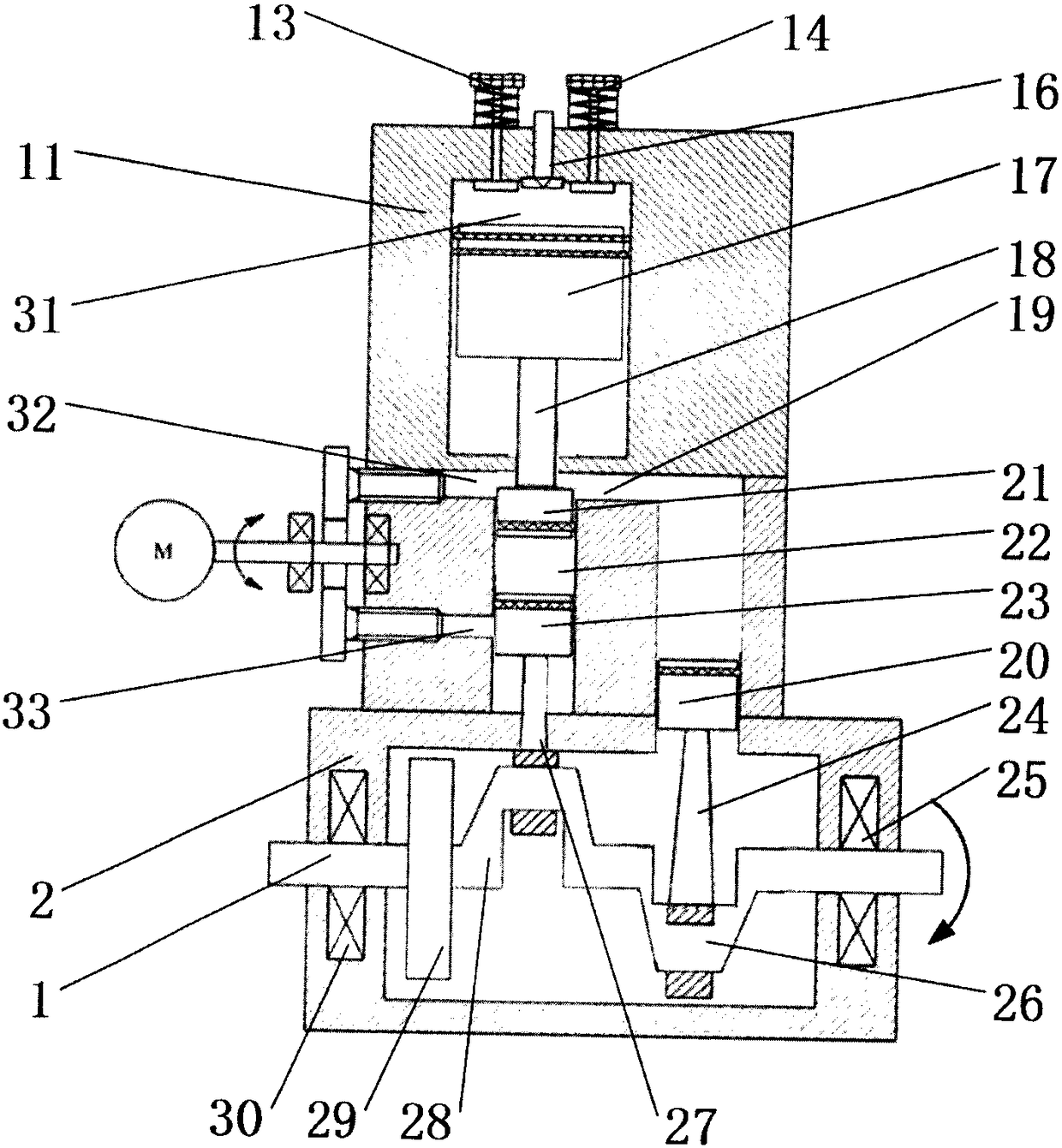

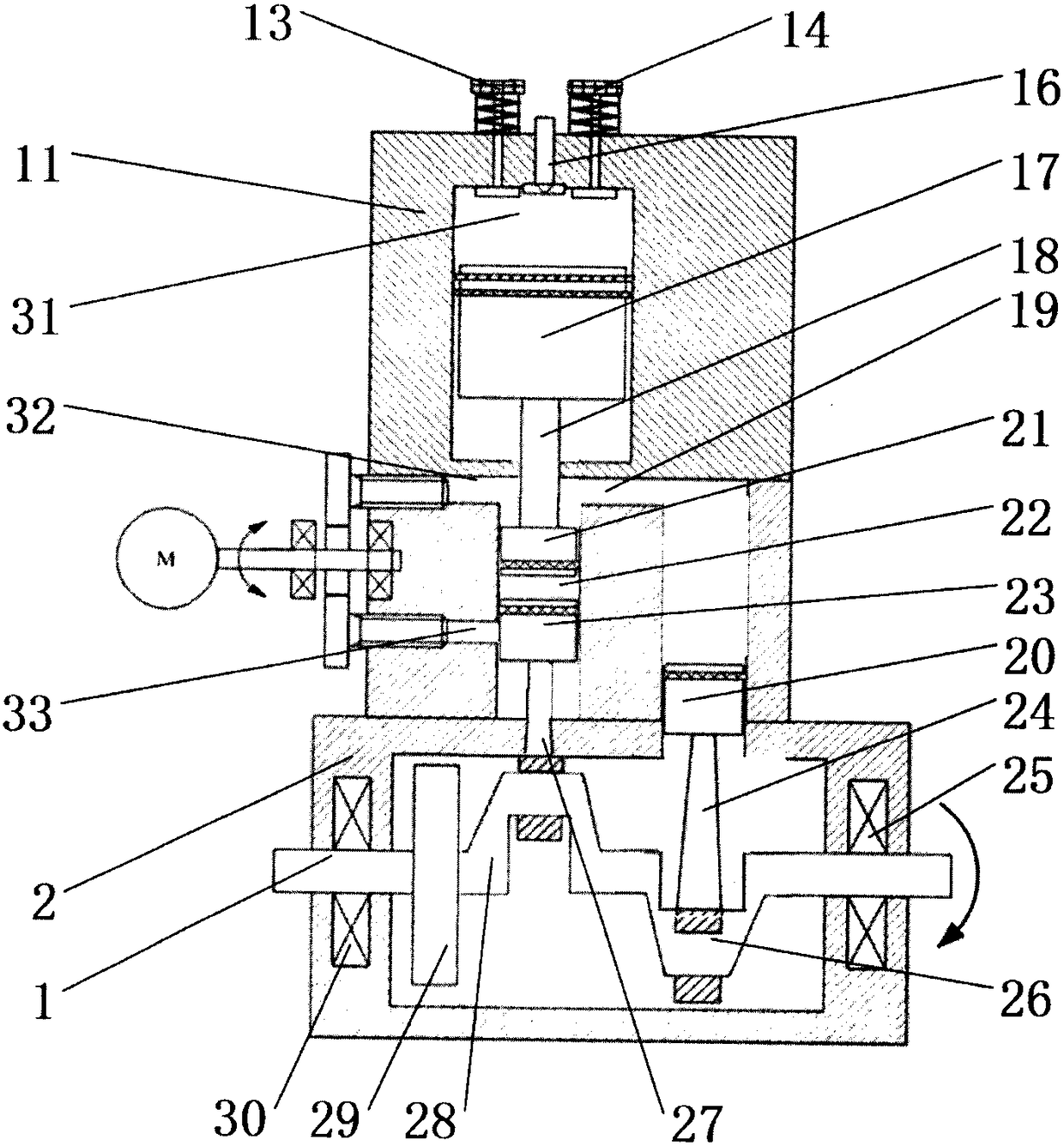

[0042] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0043] Such as figure 1 As shown, the present invention discloses a hydraulically adjustable variable compression ratio engine, which includes a cylinder block 11 and a crankcase 2. A crankshaft 1 is arranged inside the crankcase 2, and a crankshaft 1 in the cylinder block 11 is provided on the crankshaft 1. The heat energy released by the combustion of gas is converted into the crank B28 of mechanical energy for the rotation of the crankshaft 1. An intermediate body 3 is connected between the cylinder block 11 and the crankcase 2, and the intermediate body 3 is provided with a connection between the cylinder block 11 and the crankcase 2. A hydraulic system, the hydraulic system is used to realize the transmission of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com