Disk loading mechanism and control method of precious metal inspection machine

A control method and inspection machine technology, applied in the directions of measuring devices, instruments, measuring instrument components, etc., can solve the problems of long time consumption, large floor space, long intervals, etc., and achieve improved work efficiency, short space distance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

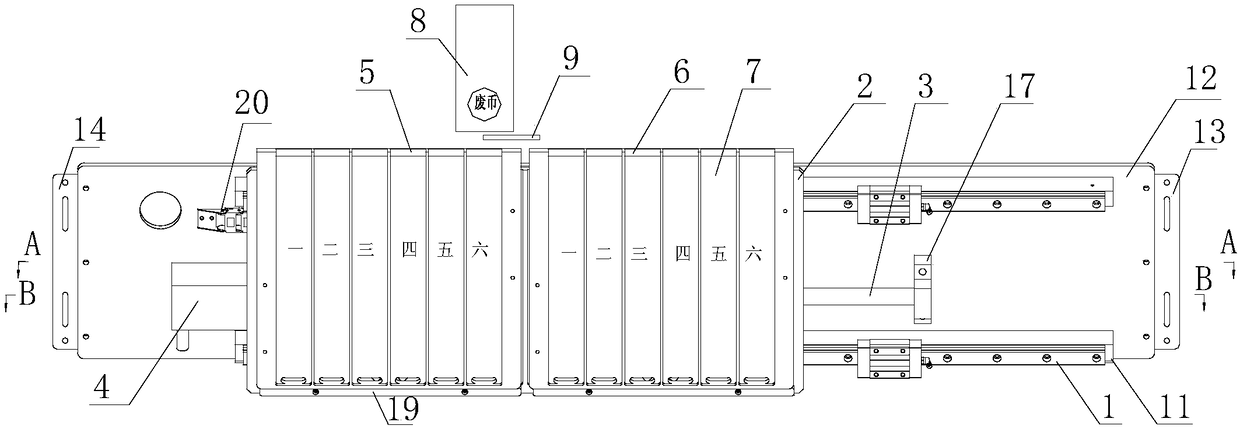

[0037] The disk loading mechanism of the precious metal inspection machine in this embodiment has a structure such as Figure 1 to Figure 4 As shown, it includes two slide rails 1, a control module, a motor 4, a screw mandrel 3, a coin feeding belt 8, a feed sensor 9 and a micro-motion sensor, wherein the feed sensor 9 is used for real-time collection of the movement of the coin feeding belt 8. The number of coins and the number of coins collected are sent to the control module, and then the control module judges whether a certain row of coin storage parts 7 of the waste coin tray is full according to the number of coins collected by the feed sensor 9; Below the plate 2, the micro-motion sensor is used to collect the micro-motion signal generated by the waste coin tray on the supporting plate 2, and transmit the micro-motion signal to the control module, and then the control module is based on the micro-motion signal collected by the micro-motion sensor Whether the waste coin ...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that six partition plates are evenly arranged along the width direction of the first waste coin tray, and the first waste coin tray is divided into seven rows of coin storage parts with the same size. Six partition plates are evenly arranged on the second waste coin tray along its width direction, and divide the second waste coin tray into seven rows of coin storage parts with the same size.

[0050] In the control method of the loading mechanism of the precious metal inspection machine in this embodiment, the loading sequence of the first waste coin tray is six, four, two, one, three, five, and seven; the loading sequence of the second waste coin tray is: one , three, five, seven, six, four, two.

Embodiment 3

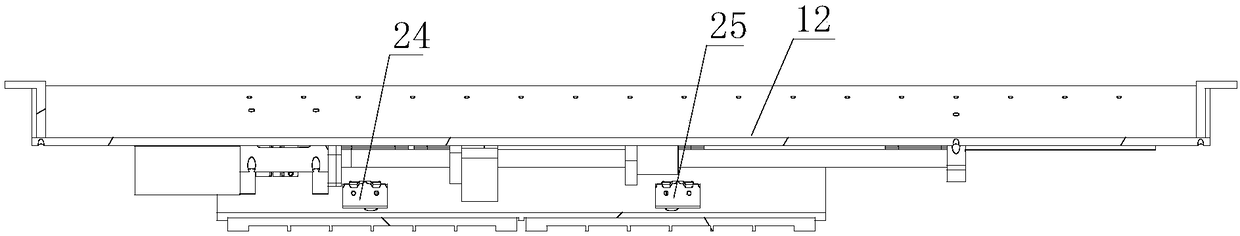

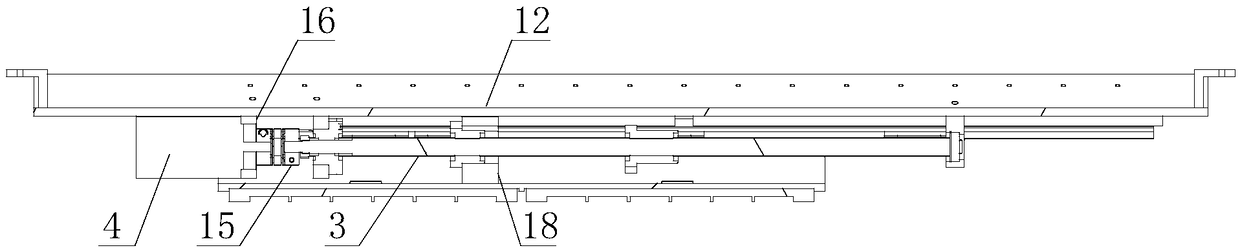

[0052] The difference between this embodiment and Embodiment 1 is that the first installation bracket 23 is arranged on the side of the motor 4 on the slide rail fixing plate 12, and the first installation bracket 23 connects with the first tow cable through the first tow cable fixing frame 21. 20 connection, the first installation bracket 23 is also connected with the first micro-motion sensor 24 through the first micro-motion sensor bracket 22, one end of the first streamer 20 is connected with the supporting plate 2, and the other end is connected with the slide rail fixing plate 12, the second The effect of a streamer 20 is to facilitate the control line of the first micro-motion sensor 24 to pass therethrough; on the side of the slide rail fixing plate 12 away from the motor 4, a second mounting bracket is provided, and the second mounting bracket passes through the second streamer The fixing frame is connected with the second streamer, and the second mounting bracket is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com