A deep trench filling method

A filling method and deep trench technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of inconsistent PN volume ratio and reduce the withstand voltage capacity of the depletion region, so as to reduce the difference of impurity amount and reduce the filling time , The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

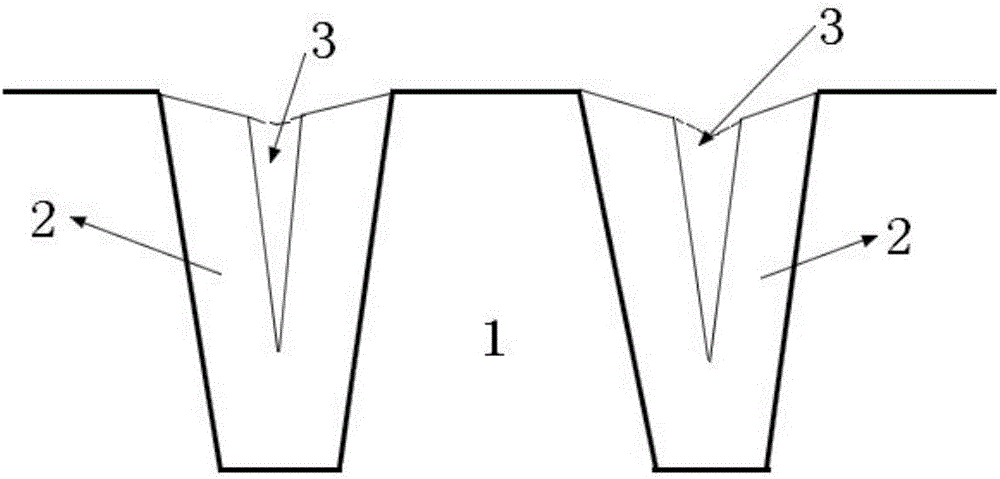

[0016] Deep trench filling method of the present invention, such as image 3 As shown, there is a deep trench in the substrate 1. In the deep trench, it is first filled with P-type or N-type epitaxy 2, and the epitaxy 2 is filled to the extent that the epitaxy of the sidewall of the trench is closed after the bottom is closed and before the top is closed. Then use a non-conductive medium such as silicon dioxide or non-doped polysilicon to continue filling the remaining space in the trench until the trench is fully filled.

[0017] The general filling time is 30% to 80% of the full filling time.

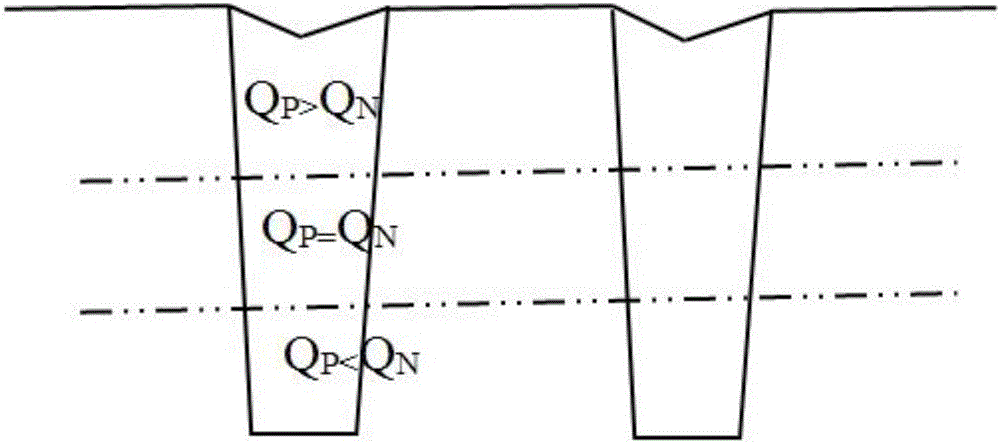

[0018] During epitaxial filling, since the epitaxial growth is constant growth along the sidewall of the deep trench, the epitaxial growth is stopped during the period from the bottom of the epitaxial to the top of the close, and the concentration of the epitaxial is calculated by the actual filled epitaxial thickness. refer to:

[0019] N epitaxial concentration × N epitaxial width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com