Super junction device and manufacturing method thereof

A technology of super junction devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing the difficulty of process control, small P-pillar width, and large deviation of breakdown voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

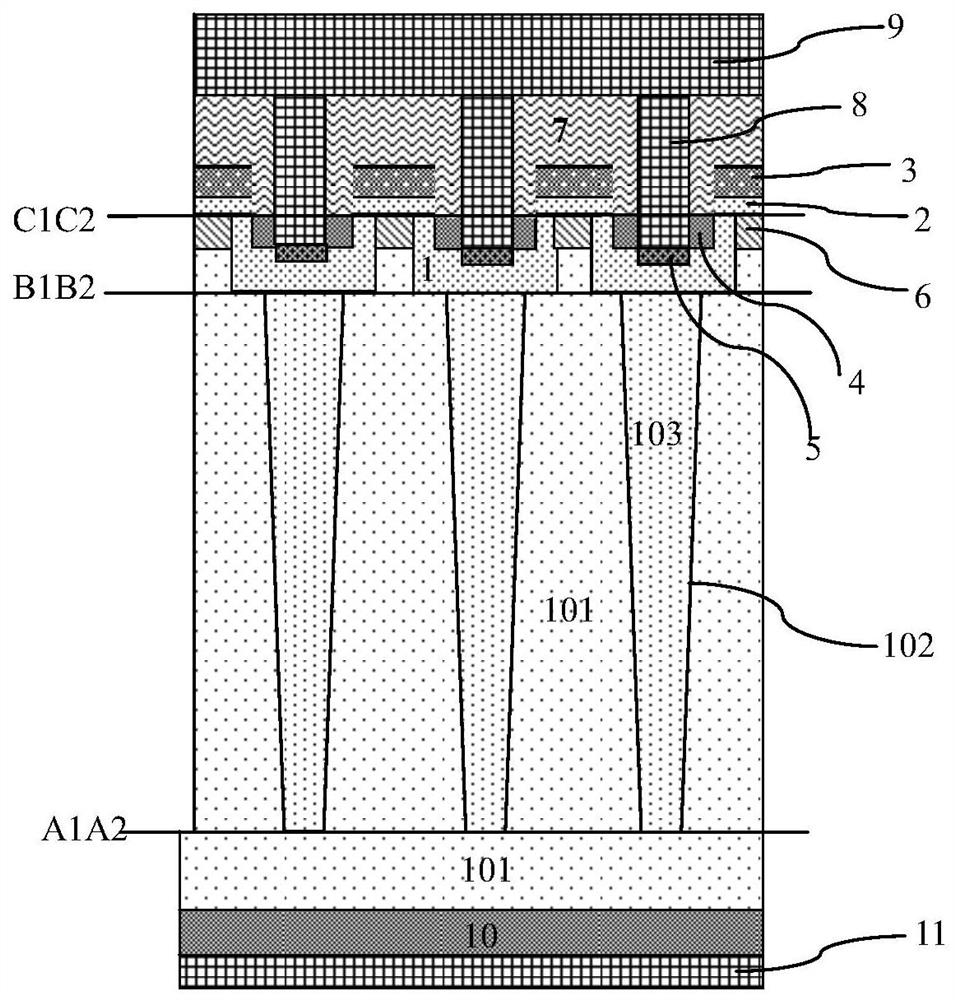

[0058] Existing superjunction devices:

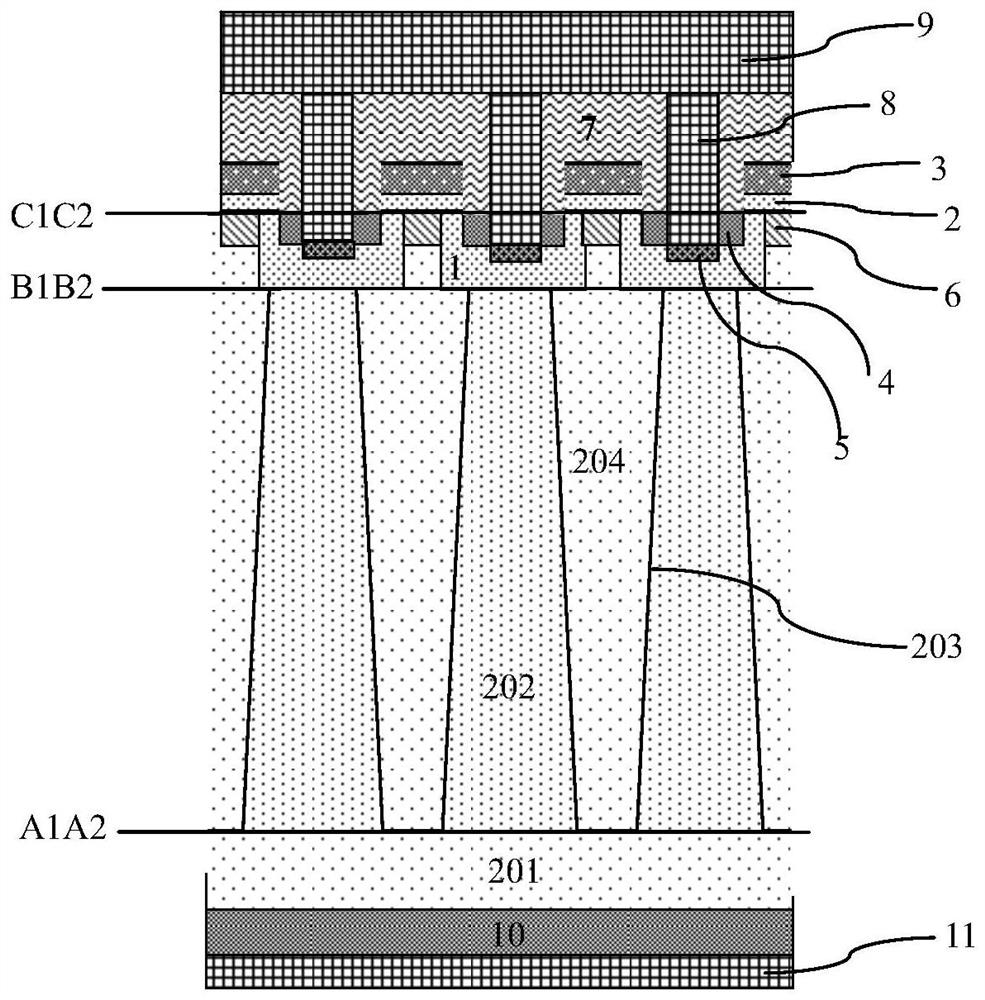

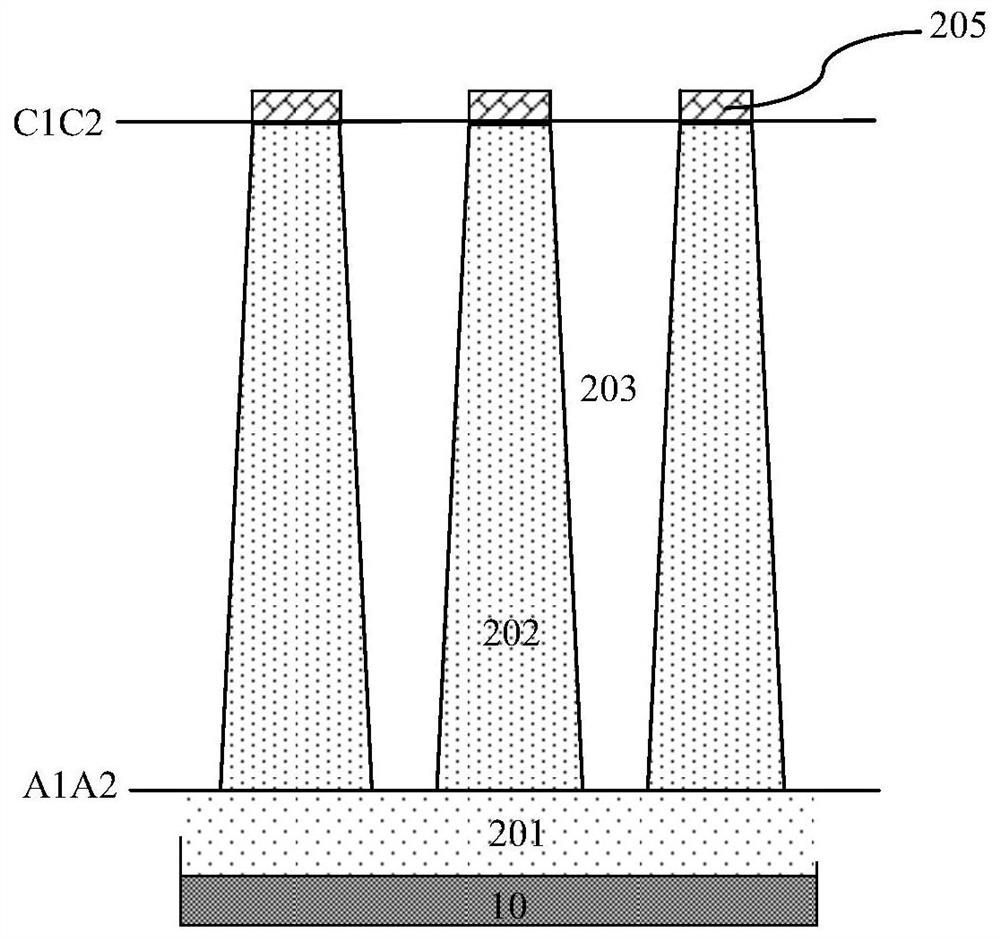

[0059] In order to compare with the super junction device of the first embodiment of the present invention, first introduce the existing super junction device, such as figure 1 Shown is a schematic structural view of an existing super junction device; the existing super junction device includes a super junction structure formed by alternating arrangement of P-type columns 103 and N-type columns 101; the super-junction device is an N-type device and is formed on the super junction In junction structure: one P-type pillar 103 and one adjacent N-type pillar 101 form a super junction unit.

[0060] In the prior art, the P-type column 103 is composed of a P-type epitaxial layer filled in the trench 102 . The N-type column 101 is composed of the N-type epitaxial layer 101 between the trenches 102 . The trench 102 is located in the N-type epitaxial layer 101 , and the N-type epitaxial layer 101 at the bottom of the trench 102 serves as a buf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com