Low-voltage MOSFET device with antistatic protection structure and manufacturing method therefor

An electrostatic protection and device technology, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve the problem that the characteristic resistance of low-voltage MOSFET cannot be optimized, the process flow and production cost increase, and the overall performance of the device cannot be improved. and other problems, to achieve the effect of saving processing time, reducing production costs, and compatible process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific drawings and embodiments.

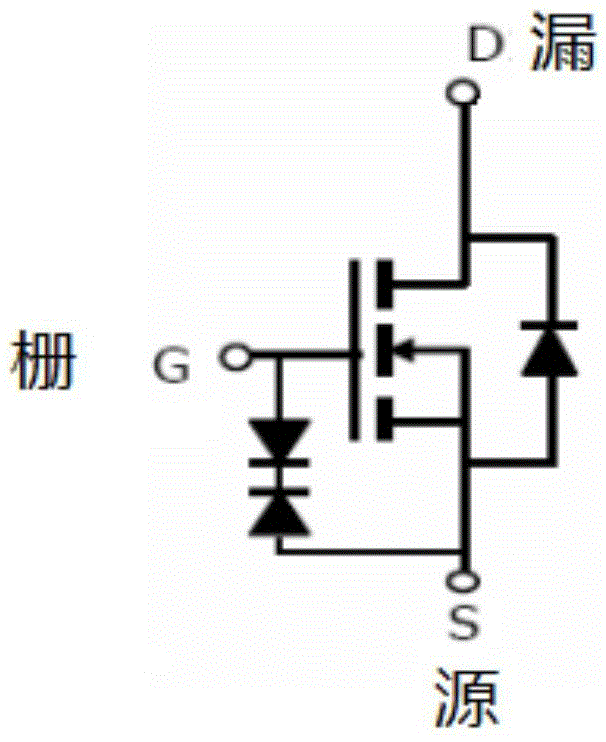

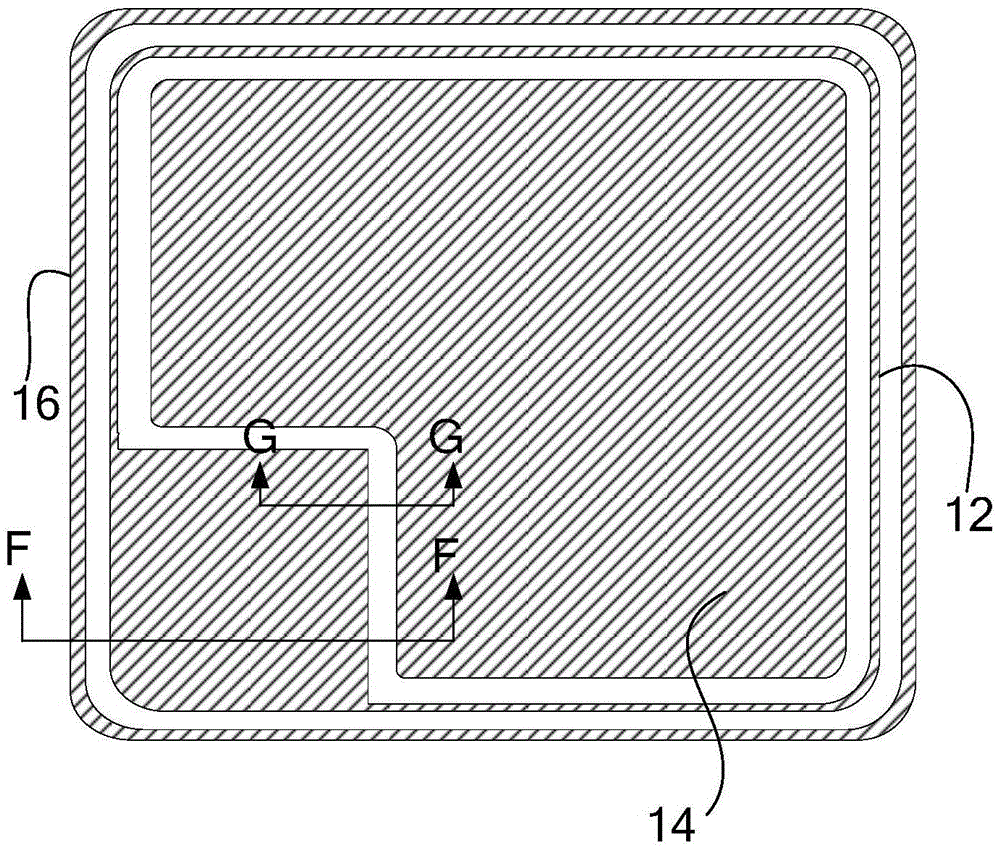

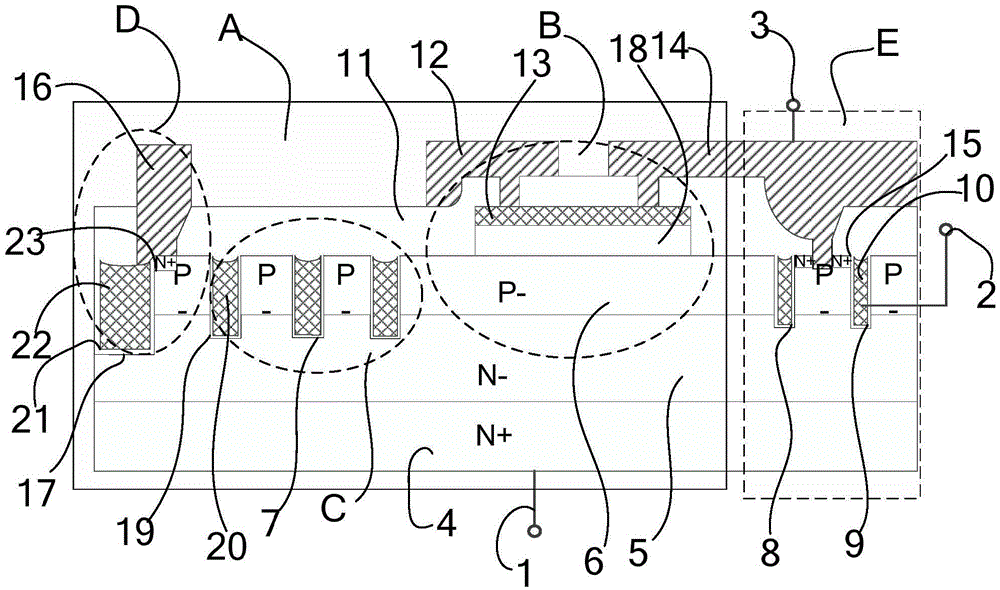

[0035] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown: in order to improve the withstand voltage of devices with ESD protection and reduce manufacturing costs, taking an N-type low-voltage MOSFET device as an example, the present invention includes a cell region E and a terminal on the semiconductor substrate on the top view plane of the MOSFET device In the protected area A, the cellular area E is located in the central area of the semiconductor substrate, and the terminal protected area A is located in the outer circle of the cellular area and surrounds the cellular area A; the terminal protected area A includes the adjacent cellular area A An electrostatic protection zone B; on the cross section of the MOSFET device, the semiconductor substrate includes an upper N-type drift region 5 and a lower N+ substrate 4, the N+ substrate 4 is adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com