Method for manufacturing parallel-series thin film battery pack

A thin-film battery and component technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, and circuits, can solve problems such as poor uniformity of the film layer, reduced power generation, and poor laser marking, so as to increase the effective area and reduce the impact. , Reduce the effect of hot spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples.

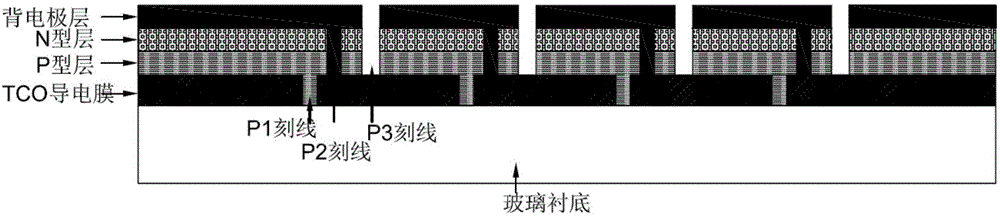

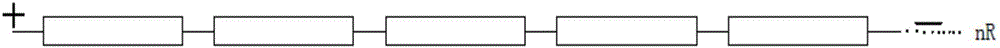

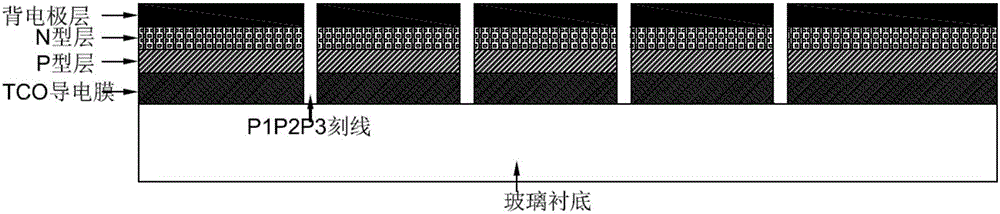

[0031] The preparation method of thin-film battery modules that are first connected in parallel and then connected in series in this embodiment is mainly to separate two or more sub-batteries on a piece of TCO conductive glass by laser scribing, and then connect the sub-batteries in parallel with drain strips. Then use the bus bar to make it in series, which includes the following steps:

[0032] 1) After the rectangular TCO conductive glass is ground and cleaned, the automatic transfer station sends the TCO conductive glass to the first laser equipment for marking, and the first laser marking line (P1 for short) is drawn parallel to the short side according to the process requirements TCO conductive film layer or coating layer (such as Image 6 shown), and run through the two long sides of the glass, and then evenly mark the conductive film or coating layer of the whole glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com