A kind of high uniformity red LED epitaxy structure and preparation method thereof

A technology of epitaxial structure and uniformity, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that the output rate of the die cannot be improved, and the influence of the surface oxide layer cannot be eliminated, so as to improve the uniformity of brightness and the finished product of the die Yield, Reduced Edge Effects, Effects of Reduced Deposition Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

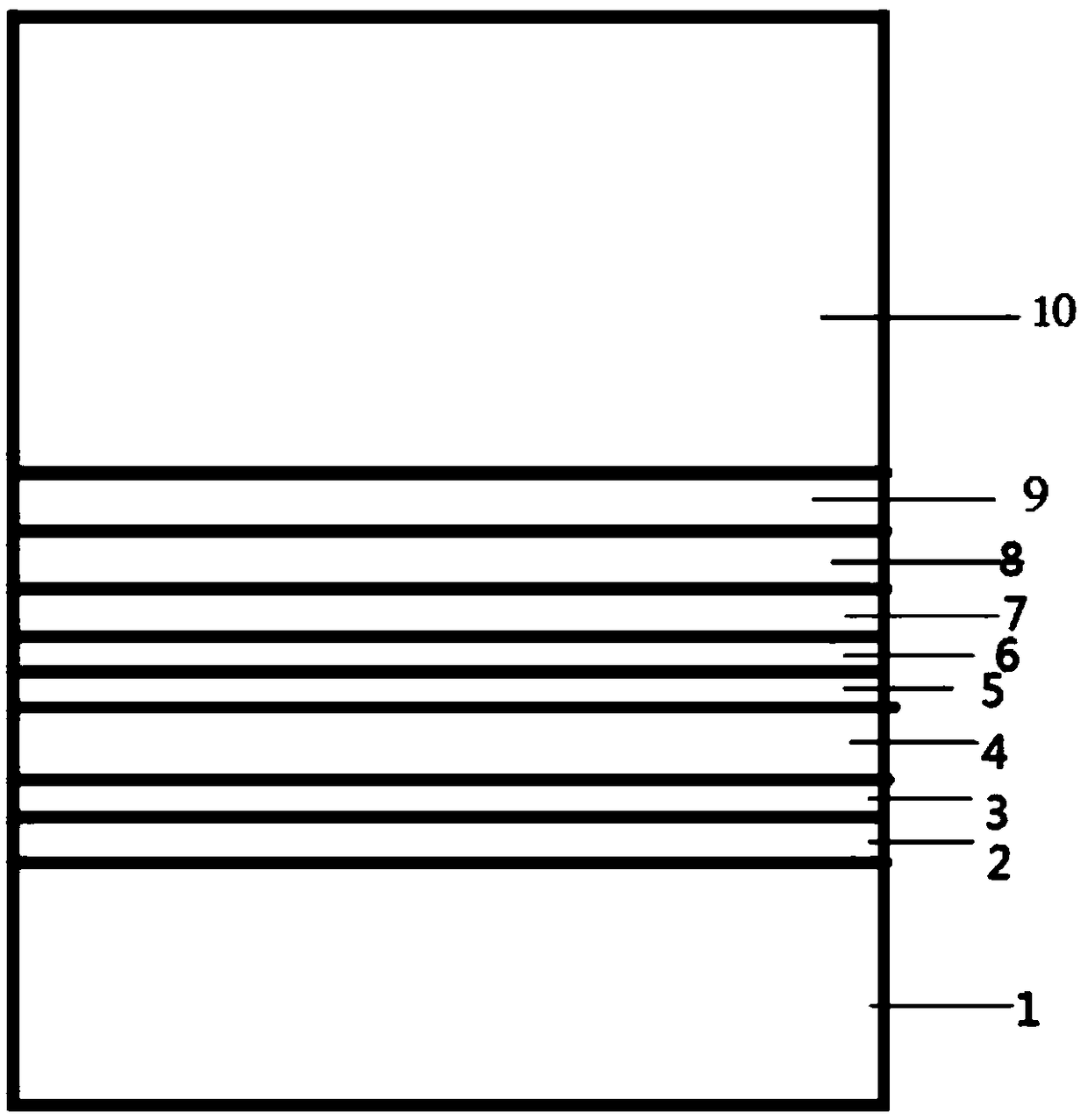

[0055] A high-uniformity red LED epitaxial structure, such as figure 1 As shown, it includes GaAs substrate 1, AlGaAs buffer layer 2, GaAs buffer layer 3, AlGaAs / AlAs DBR4, AlInP N confinement layer 5, AlGaInP N waveguide layer 6, MQW quantum well active layer 7 arranged in sequence from bottom to top , AlGaInP P waveguide layer 8, AlInP P confinement layer 9, GaP window layer 10.

[0056] The AlGaAs buffer layer 2 is used to eliminate the influence of the oxide layer on the surface of the GaAs substrate 1 on the epitaxial growth quality and improve the quality of the epitaxial growth; the GaAs buffer layer 3 is used to achieve perfect lattice matching with the GaAs substrate 1 to avoid the GaAs substrate 1 surface The defects and dislocations brought by the new growth material, and provide a fresh interface for the next growth; AlGaAs / AlAs DBR4 constitutes a composite Bragg reflection layer, which uses a periodic layered structure composed of two materials with different refr...

Embodiment 2

[0059] A kind of high uniformity red light LED epitaxial structure described in embodiment 1, its difference is that,

[0060] The thickness of the AlGaAs buffer layer 2 is 0.8 μm, and the carrier concentration is 5E18cm -3 . The thickness of GaAs substrate 1 is 375 μm; the thickness of GaAs buffer layer 3 is 0.5 μm, and the carrier concentration is 5E18cm -3 ; AlGaAs / AlAs DBR4 includes 30 pairs of AlGaAs / AlAs DBR4, the carrier concentration is 5E18cm -3 ; Each AlGaAs / AlAs DBR4 growth cycle period is a pair of AlGaAs / AlAs DBR4, and the AlGaAs / AlAs DBR4 logarithm can be grown according to the brightness required; the thickness of the AlInP N confinement layer 5 is 1 μm, and the carrier concentration is 5E18cm -3 , the III-V group ratio is 200; the AlGaInP N waveguide layer 6 has a thickness of 0.5 μm and is not doped, and the III-V group ratio is 350; the MQW quantum well active layer 7 has a thickness of 0.5 μm, is not doped, and has a III-V group ratio of 350. ratio is 350...

Embodiment 3

[0062] A kind of high uniformity red light LED epitaxial structure described in embodiment 1, its difference is that,

[0063] The thickness of the AlGaAs buffer layer 2 is 0.5 μm, and the carrier concentration is 6E17cm -3 . The thickness of GaAs substrate 1 is 310 μm; the thickness of GaAs buffer layer 3 is 0.4 μm, and the carrier concentration is 6E17cm- 3 ; AlGaAs / AlAs DBR4 includes 15 pairs of AlGaAs / AlAs DBR4, the carrier concentration is 6E17cm -3 ; Each AlGaAs / AlAs DBR4 growth cycle period is a pair of AlGaAs / AlAs DBR4, and the AlGaAs / AlAs DBR4 logarithm can be adjusted according to the brightness required by the growth; the thickness of the AlInP N confinement layer 5 is 0.7 μm, and the carrier concentration is 6E17cm -3 , the III-V group ratio is 100; the AlGaInP N waveguide layer 6 has a thickness of 0.3 μm, no doping, and the III-V group ratio is 200; the MQW quantum well active layer 7 has a thickness of 0.3 μm, undoped, and the III-V group ratio is 0.3 μm. rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com