Lithium battery assembly capable of providing high discharge pulse within wide temperature range, and forming method

A technology of lithium batteries and lithium-ion batteries, applied in electrical components, secondary batteries, circuits, etc., can solve problems such as poor low-temperature performance and limited applications, and achieve the effect of reducing aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In order to demonstrate the superior performance of the embodiment of the present invention, a rechargeable secondary lithium-ion battery was constructed according to the scheme involved in the present invention, and related basic tests were carried out.

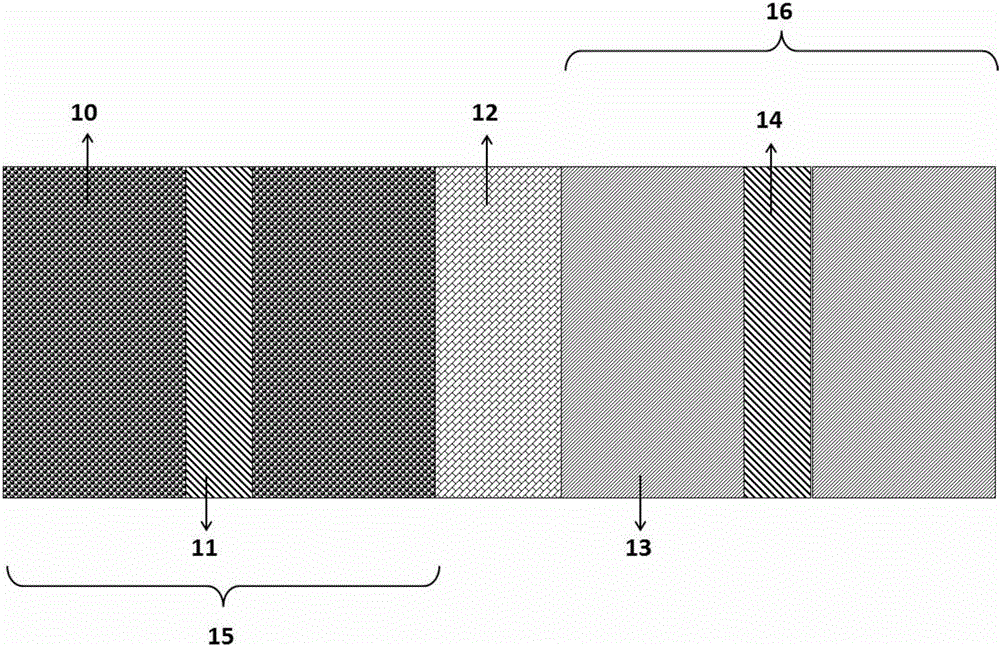

[0049] A pouch type test battery was fabricated using the following components. The anode is made of 9-micron copper foil, and a carbon-based anode: carbon powder: PVDF (80:10:10w%) hard material mixture layer is coated on both sides of the copper foil with a thickness of 27.5 microns (each side). The carbon-based anode material particles are flakes with a thickness of 100-200 nanometers and a diameter of 500 nanometers to 5 micrometers, the total thickness of the anode is 64 micrometers, the width of the anode is 22 millimeters, and the length of the anode is 1185 millimeters. Herein, "w%" all represent mass percent.

[0050] The cathode selects 20 micron aluminum foil as the carrier, and the cathode material with a...

Embodiment 2

[0053] Lithium-ion batteries were manufactured using the processes and materials described in Example 1 above, wherein the anode material used was a spherical carbon-based anode material, and the particle size of the spherical carbon-based anode material was 1 micron to 10 microns. The battery prepared in this embodiment is charged and discharged with a current of 1C in the voltage range of 2.75-3.76, and the measured capacity is about 35mAh.

Embodiment 3

[0055] The flow process and materials described in the above-mentioned embodiment 1 are used to manufacture lithium-ion batteries, wherein the anode material uses a sheet-like carbon-based material, and the particle thickness of the sheet-like carbon-based material is 500 nanometers to 21 microns, and the diameter is 30 microns to 100 microns. The battery is charged and discharged with a current of 1C within the voltage range of 2.75-3.76, and its measured capacity is about 47mAh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com