Converter tilting DC control system and current sharing method

A DC control system, converter technology, applied in the control system, DC motor speed/torque control, electrical components, etc., can solve the problems of explosive and fast melting, uneven current, and performance differences of the silicon controlled rectifiers of the four devices, etc. Achieve the effect of ensuring safe production and improving current sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

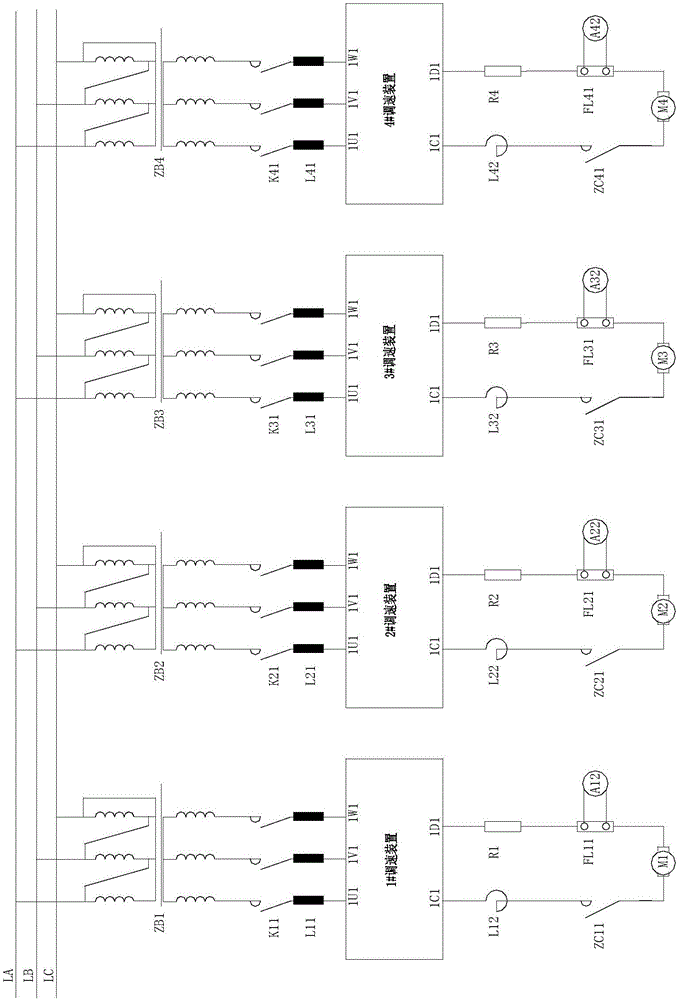

[0042] Remove the parallel connection on the output side of the four speed control devices in the original plan to realize decoupling control electrically. In actual operation, due to the accumulated gear clearance of the multi-stage reduction box, the four motors are no longer rigidly connected in theory, but It is by no means a theoretically flexible connection. It is called a rigid connection with gaps. There is no master-slave distinction in control, and it is relatively independent in speed control. Therefore, to transform the existing scheme, the structure of the converter tilting DC control system is shown in figure 1 :

[0043] An independent rectifier transformer is installed for each speed regulating device on the AC incoming line side, and it also plays the role of electrical isolation among the units. Set smoothing reactors for each speed control device on the AC incoming line side. Add 10% softening resistance to each motor armature on the output side of the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com